Rice preservation method and device

A technology of rice and equipment, applied in the field of rice preservation, to improve the quality of rice, reduce water loss, and avoid yellowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

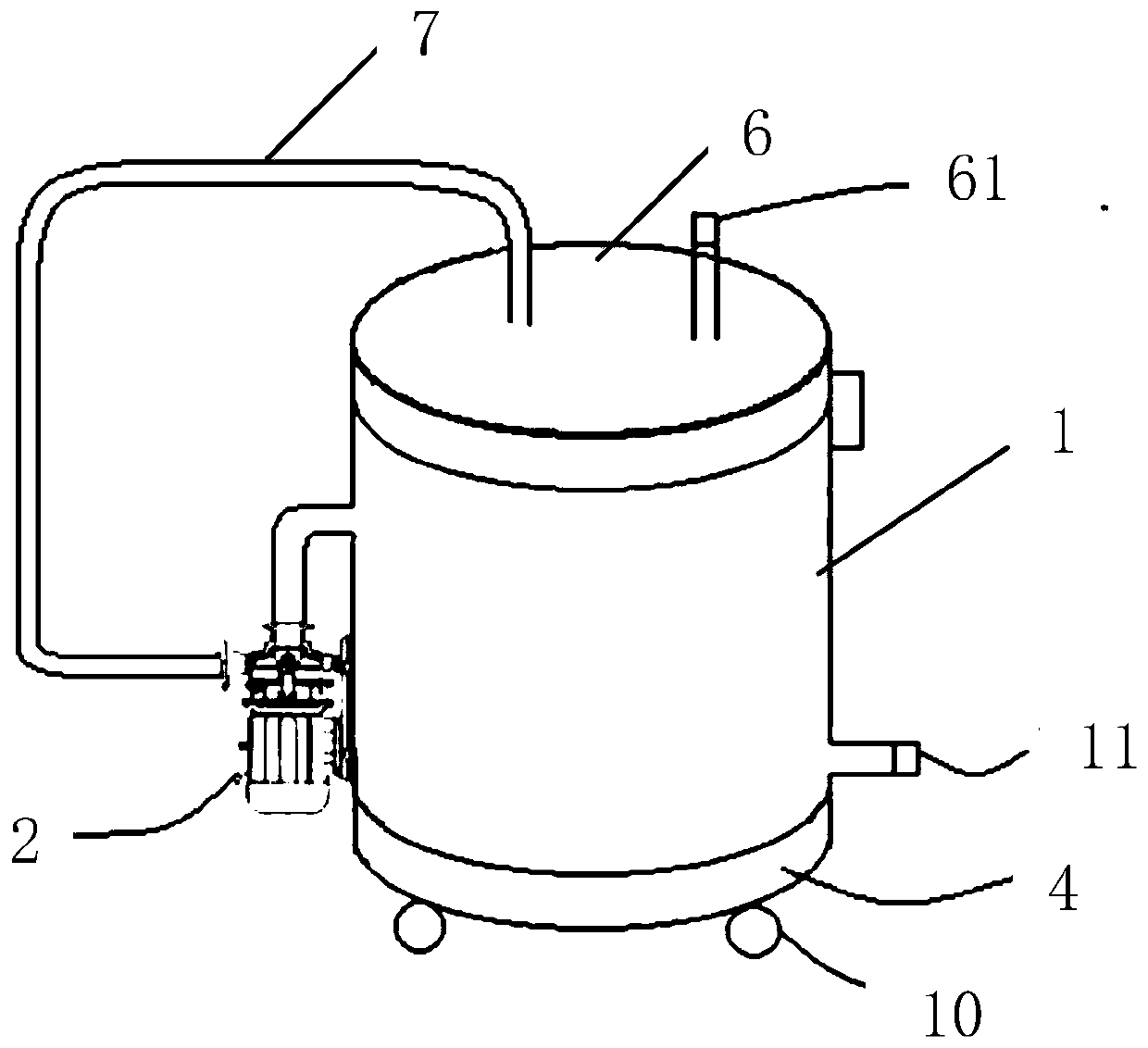

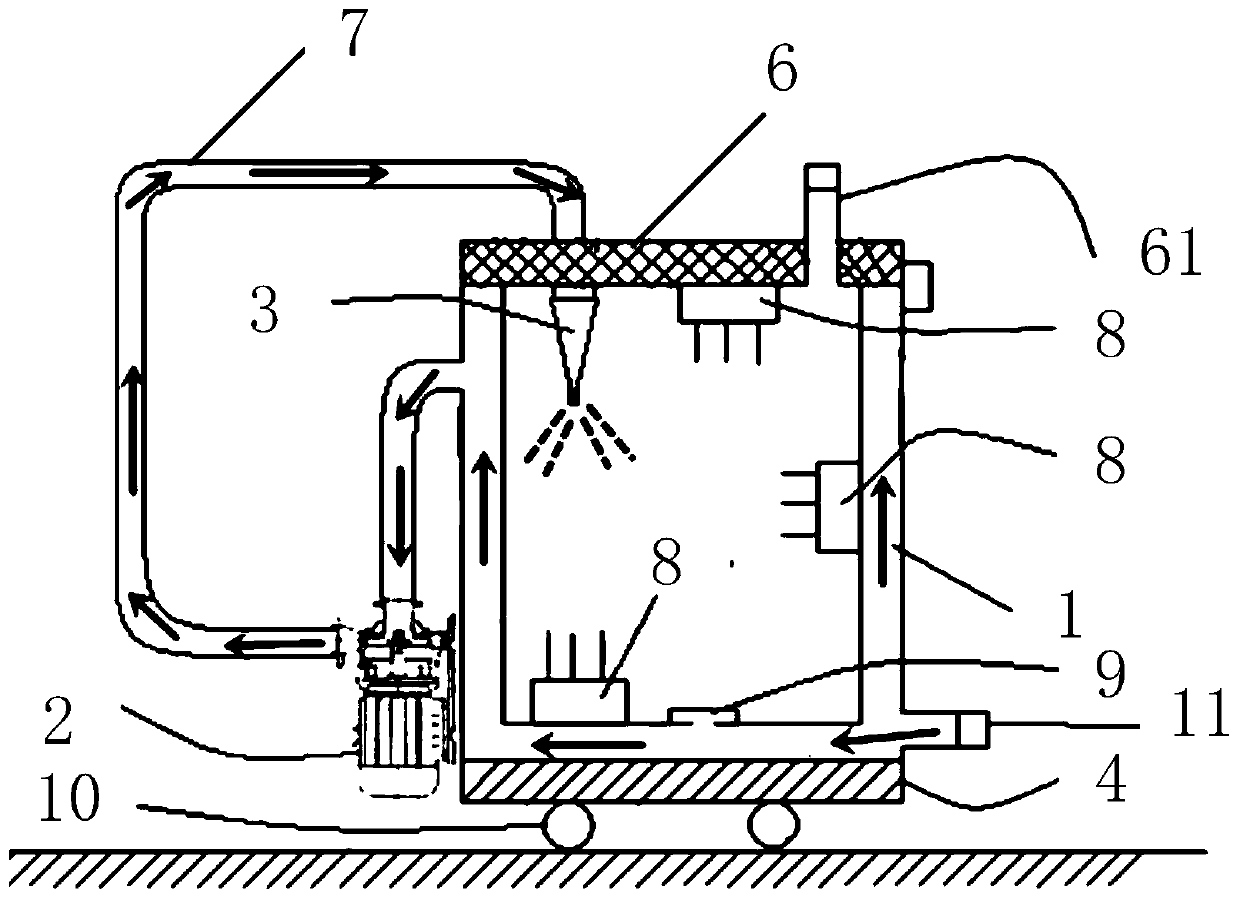

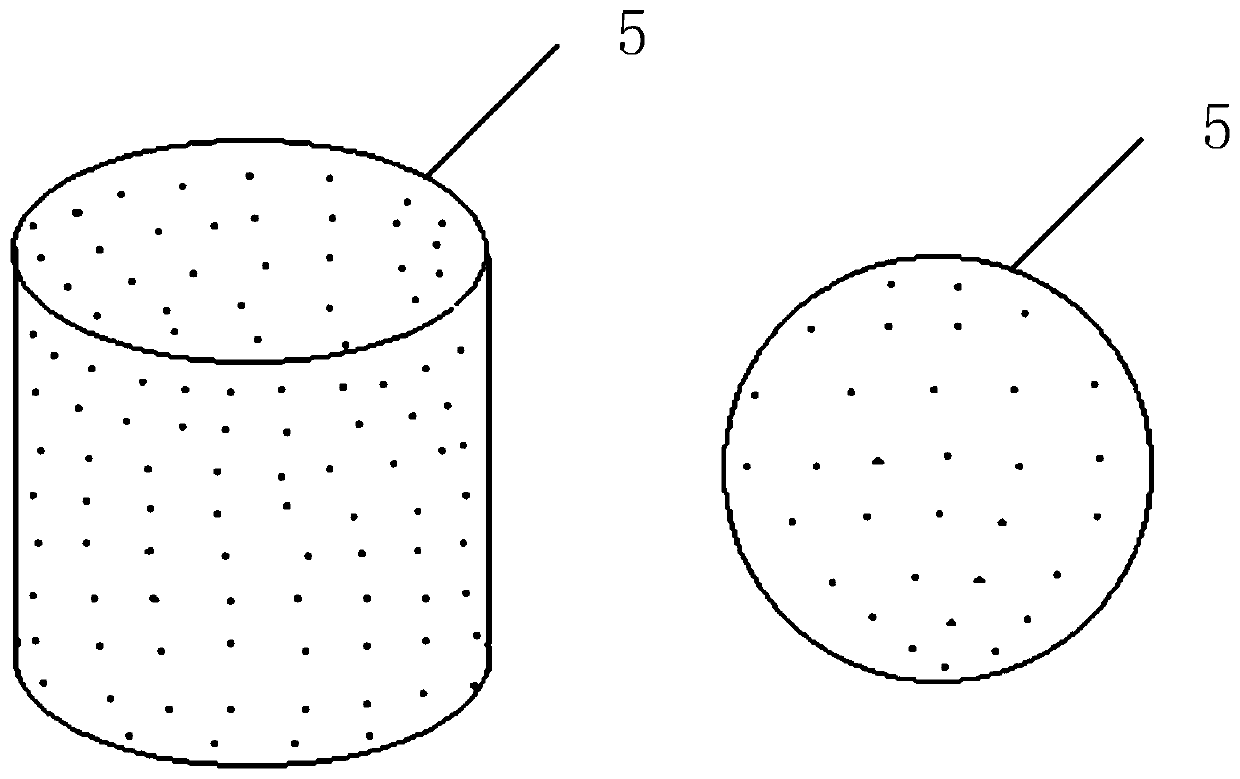

[0044] Embodiment 1 of the present invention provides a kind of equipment for keeping rice fresh, such as Figure 1-Figure 4 As shown, it includes a jacket cavity 1 that can inject solutions, a water pump 2, an ultrasonic nebulizer 3 (or an evaporative molecular sieve humidifier), a heating base 4, a porous container 5 and a cover 6, specifically:

[0045] The porous container 5 is used to hold cooked rice, and the porous container 5 is arranged in the inner container of the jacket cavity 1 during operation;

[0046] The water pump 2 is arranged on the outer wall of the jacket cavity 1, and injects water into the jacket cavity 1 through the water pipe 7 to realize diversion; the other end of the water pump 2 is connected to the ultrasonic atomizer 3 (or evaporative molecular sieve humidifier), used to supply the water drained from the jacket cavity 1 to the ultrasonic nebulizer 3 (or evaporative molecular sieve humidifier); wherein, the ultrasonic nebulizer 3 (or evaporative m...

Embodiment 2

[0061] After providing the device for rice preservation as described in Example 1, the present invention also provides a method for keeping rice fresh, using the device for keeping rice fresh as described in Example 1, and associated preferred implementation solutions, pre-configured for Import the solution of the jacket cavity 1, and adopt various steaming methods to obtain the rice to be kept fresh, such as Image 6 As shown, specifically:

[0062] In step 201 , inject the solution into the jacket cavity 1 , cover the lid 6 , and turn on the heating base 4 .

[0063] In step 202, when the temperature of the solution rises to the first target temperature, the water pump 2 and the ultrasonic nebulizer 3 (or evaporative molecular sieve humidifier) are turned on to atomize the solution at the first target temperature and pass it into the clip through a pipeline. Jacket the inner tank of the cavity 1 so that the relative humidity of the inner tank of the jacket cavity 1 is not...

Embodiment 3

[0074] The embodiment of the present invention is based on the rice preservation equipment provided in Embodiment 1 and the rice preservation method provided in Embodiment 2. The embodiment of the present invention is further equipped with a set of optimal parameters to realize the method process. The embodiment of the present invention provides a special fresh-keeping method for rice controlled by environmental factors, which is used for instant fresh-keeping of rice after cooking. The rice fresh-keeping equipment described in the above is also referred to as equipment for short, and in the embodiment of the present invention, an ultrasonic atomizer is used for discussion. Embodiments of the present invention include the following steps:

[0075] 1. Preparation of raw and auxiliary materials: cooked rice, water;

[0076] 2. Equipment preheating: While cooking rice, it is necessary to start preheating the rice preservation equipment. Fill the jacket with distilled water or t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com