EPS semi-automatic gear-shifting system

A semi-automatic, shifting cylinder technology, applied in the direction of transmission control, toothed components, belts/chains/gears, etc., can solve the problems of economical reduction, driving cost increase, low safety, etc., to reduce gear shifting Control strength, increase shift response speed, and save installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

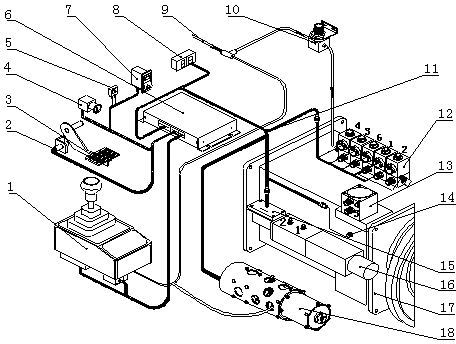

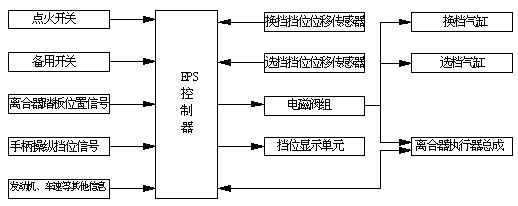

[0015] The structure and principle of the EPS semi-automatic shift system of the present invention are as follows: figure 1 and figure 2 As shown, the mechanical gearbox 17 is the control body of the entire system, and the shift cylinder 16 and the gear selection cylinder 13 are fixedly installed on the casing of the gearbox 17 in an orthogonal manner. The gear shift cylinder 16 controls the gear shift fork in the gearbox 17 to realize gear shifting, and the gear selector cylinder 13 controls the gear selector shaft in the gearbox 17 to realize gear position selection, and the two coordinate motion to realize vehicle gear shifting. The shift position feedback unit 15 is installed on the shift cylinder 16, and the position sensing is realized by a Hall sensor group, which is used to feed back the position information of the piston in the shift cylinder 16, that is, to determine the position of the shift fork. The gear selection cylinder displacement sensor 14 is installed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com