Refrigerator with variable temperature chamber having nitrogen fresh-keeping function

A technology for changing greenhouses and refrigerators, which is applied in household refrigerators, food preservation, household appliances, etc. It can solve problems such as difficulty in productization, low compressive strength, and hidden dangers of air pressure leakage, and achieve convenient operation, slow down losses, The effect of maintaining quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

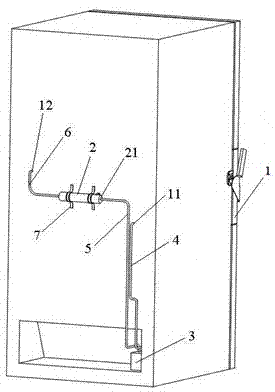

[0031] Such as figure 1 Shown is a first embodiment of the invention, as figure 1 The refrigerator with nitrogen fresh-keeping function in the variable temperature room includes a variable temperature room 1, and also includes a gas separation device 2, an air pump 3, an air suction pipe 4, a first air outlet pipe 5, a second air outlet pipe 6 and a fixed block 7, and the variable temperature room A first interface 11 and a second interface 12 are arranged on the top, and the above-mentioned structures are all arranged on the back of the refrigerator. The air extraction pipe 4 is connected to the first interface 11 and the air extraction pump 3, the first air outlet pipe 5 is connected to the air extraction pump 3 and the gas separation device 2, and the second air outlet pipe 6 is connected to the gas separation device 2 and the second interface 12. The gas separation device 2 is fixedly connected to the back panel of the refrigerator by a fixing block 7 . The air pump 3 is...

Embodiment 2

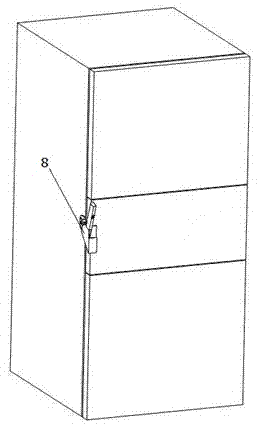

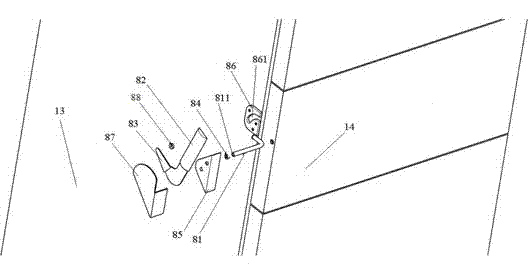

[0034] Such as figure 2 , image 3 and Figure 4 Shown is a second embodiment of the invention, as image 3 As shown, the temperature-changing room includes a box body 13 and a door body 14, figure 2 The shown variable room is also provided with a pressure relief assembly 8, which connects the box body and the door body, image 3 The pressure relief assembly shown includes an air duct 81, a handle seat 82 and a connecting rod, the handle seat 82 is fixedly connected to the connecting rod 83, the handle seat and the connecting rod form an L shape, and the air duct 81 is fixed inside the door body , the air guide pipe is provided with an air outlet 811, the air outlet 811 is connected to the outside of the variable greenhouse, the outer side of the air outlet is provided with a pipe sleeve 84, the pipe sleeve is made of soft rubber, and the connecting rod is fixedly connected with a protrusion, so The above-mentioned protrusion matches the pipe sleeve, and the protrusion i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com