Heating type humidity sensor and manufacturing method thereof

A humidity sensor and heating technology, used in humidity indicators, scientific instruments, measuring devices, etc., can solve the problems of the surface being easily polluted by water, the occurrence of frosting phenomenon, the accuracy and sensitivity of humidity testing, etc., to achieve good consistency, reduce Processing difficulty, the effect of optimizing the process route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

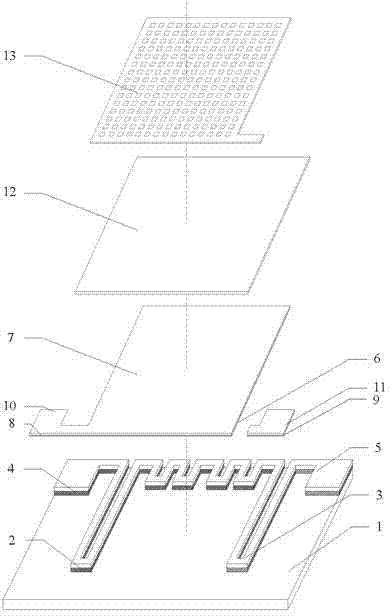

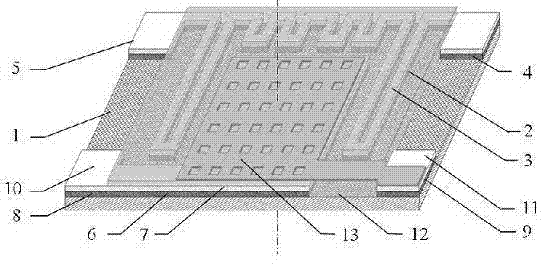

[0037] The substrate 1 of the heating humidity sensor is made of quartz, one side of the substrate 1 is a polished surface and the surface is insulated, and the thickness of the substrate 1 is 0.3 mm.

[0038] Both the heating resistor metal base layer 2 and the heating resistor pad metal base layer 4 are made of NiCr, and the thickness of the NiCr metal layer is 30nm.

[0039] Both the heating resistor 3 and the heating resistor pad 5 are made of Pt, the thickness of the Pt metal layer is 100nm, and the resistance value is 50Ω.

[0040] The metal base layer 6 of the capacitor lower electrode, the metal base layer 8 of the capacitor lower electrode pad and the metal base layer 9 of the capacitor upper electrode pad are all made of NiCr with a thickness of 100 nm.

[0041] The lower electrode 7 of the capacitor, the pad 10 of the lower electrode of the capacitor and the pad 11 of the upper electrode of the capacitor are all made of Au with a thickness of 200 nm.

[0042] The t...

Embodiment 2

[0056] The substrate 1 of the heating humidity sensor is made of glass, both sides of the substrate 1 are polished and the surface is insulated, and the thickness of the substrate 1 is 0.5mm.

[0057] Both the heating resistor metal base layer 2 and the heating resistor pad metal base layer 4 are made of Cr, and the thickness of the Cr metal layer is 50nm.

[0058] Both the heating resistor 3 and the heating resistor pad 5 are made of NiCr, the thickness of the NiCr metal layer is 200nm, and the resistance value is 70Ω.

[0059] The metal base layer 6 of the lower electrode of the capacitor, the metal base layer 8 of the pad of the lower electrode of the capacitor and the metal base layer 9 of the pad of the upper electrode of the capacitor are all made of NiCr with a thickness of 180 nm.

[0060] The lower electrode 7 of the capacitor, the pad 10 of the lower electrode of the capacitor and the pad 11 of the upper electrode of the capacitor are all made of Al with a thickness ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com