Distributed RTU (Remote Terminal Unit) system

A distributed, CAN bus technology, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problems of complex monitoring field wiring methods, increased maintenance and upgrade costs, and increased labor costs, so as to reduce later maintenance and upgrades Lower cost, convenient on-site maintenance and debugging, and reduced work load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to clearly illustrate the technical features of this solution, the present invention will be described in detail below through specific implementation modes and in conjunction with the accompanying drawings.

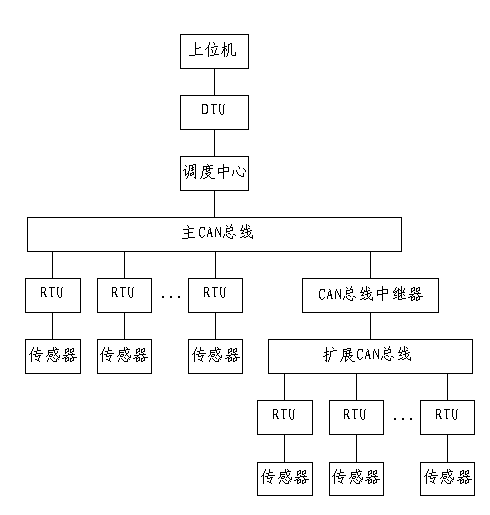

[0015] Such as figure 1 Shown, a kind of distributed RTU system of the present invention, it comprises upper computer, master controller, DTU, main CAN bus, expansion CAN bus, CAN bus repeater, some RTUs and some sensors, described RTU and on-site The sensor is connected to the field device and is connected to the main CAN bus or the extended CAN bus. The extended CAN bus is connected to the main CAN bus through a CAN bus repeater. The main CAN bus is connected to the main controller. The main controller Connect with the host computer through DTU.

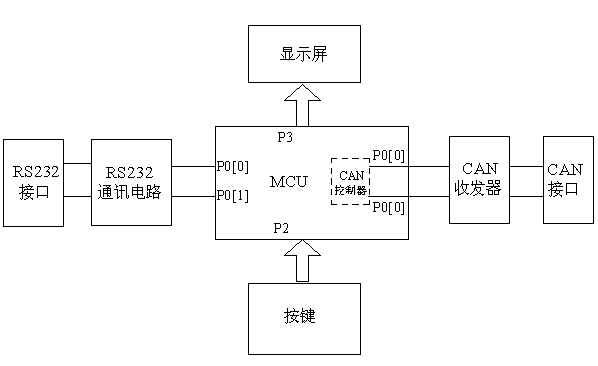

[0016] Such as figure 2 As shown, the main controller of the present invention includes MCU, CAN transceiver, CAN interface, RS232 interface, RS232 communication circuit, display screen and buttons, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com