An online debris control process for threshing and redrying

A technology for threshing and re-roasting and sundries, which is applied in the field of tobacco processing, can solve the problems of being unable to remove impurities and sundries, and achieve the effect of avoiding manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

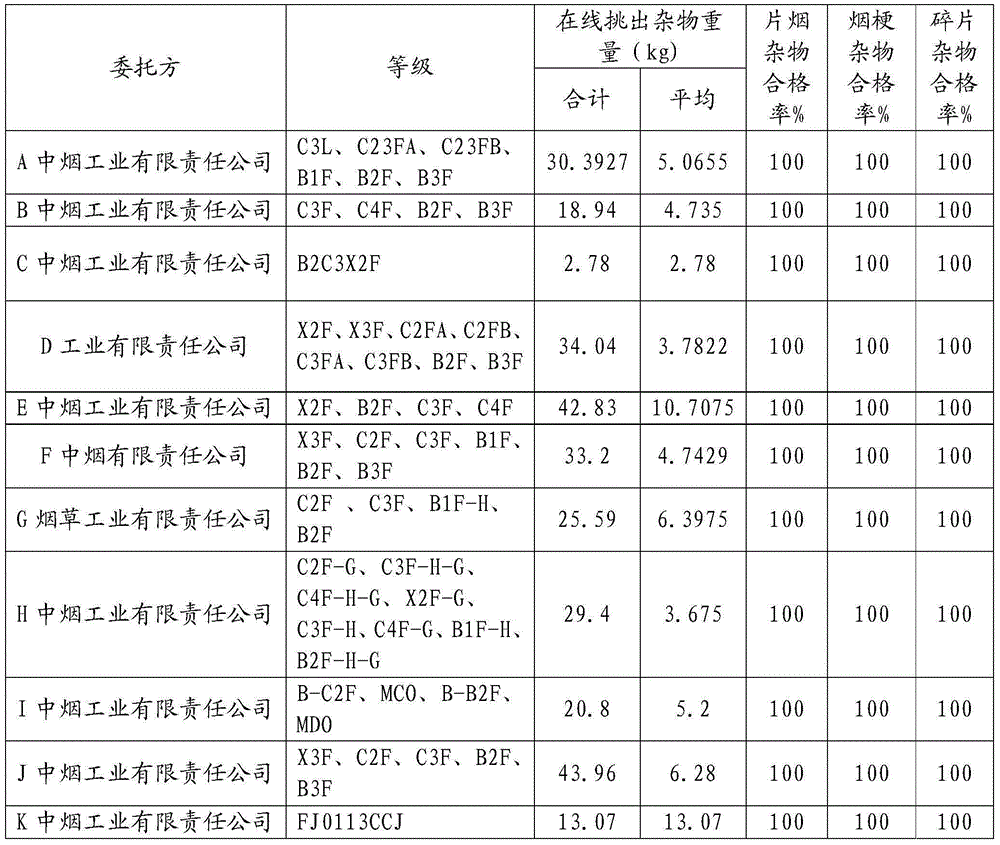

Image

Examples

Embodiment Construction

[0015] In order to describe in detail the technical content, structural features, achieved objectives and effects of the present invention, the following will be described in detail in conjunction with the embodiments.

[0016] The on-line debris control process for threshing and redrying in this embodiment includes the impurity removal in the leaf laying and feeding process, the impurity removal in the leaf moistening process, the impurity removal in the leaf threshing process and the impurity removal in the packaging process, as follows:

[0017] 1. Impurity removal in the leaf laying and feeding process

[0018] On the leaf laying line, the tobacco is debonded and the head is cut off. The winding separator is used to separate the winding from the head, and the debris in the winding is removed by manual fine selection.

[0019] 2. Leaf moistening process to remove impurities

[0020] 1) Apply drum screening technology to separate the sand and dust in the tobacco leaves afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com