Novel air-assisted stirrer

A technology of agitator and air delivery, which is applied in the field of wind slurry agitation devices, can solve the problems of high noise in mechanical operation, inconvenient disassembly and maintenance, and bulky models, so as to save energy, reduce product consistency, and produce uniform products. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation manners of the present invention will be briefly described below in conjunction with the accompanying drawings.

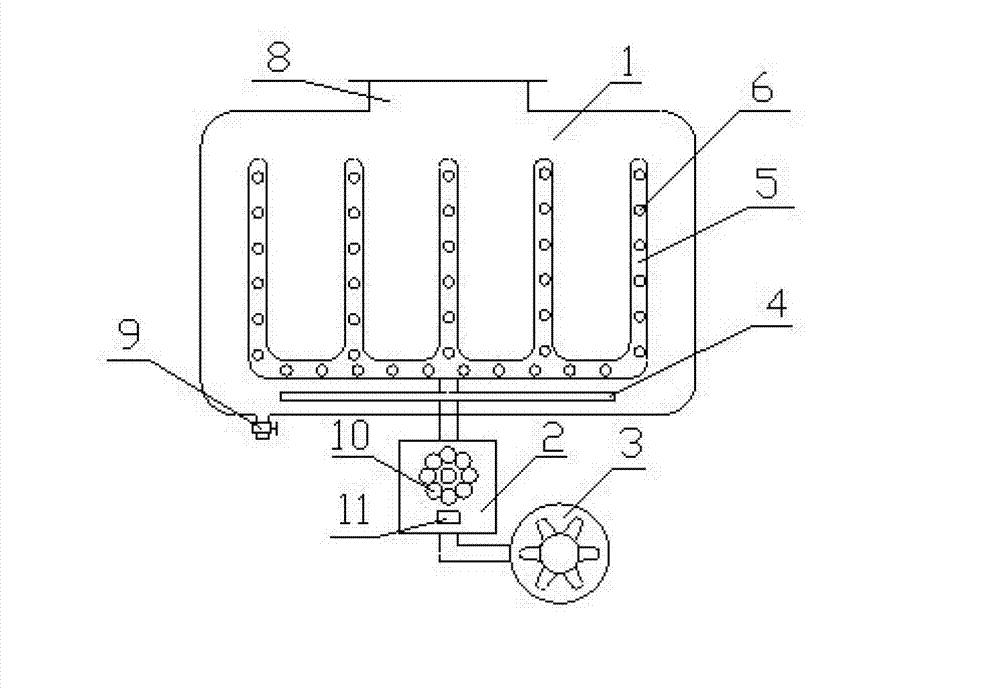

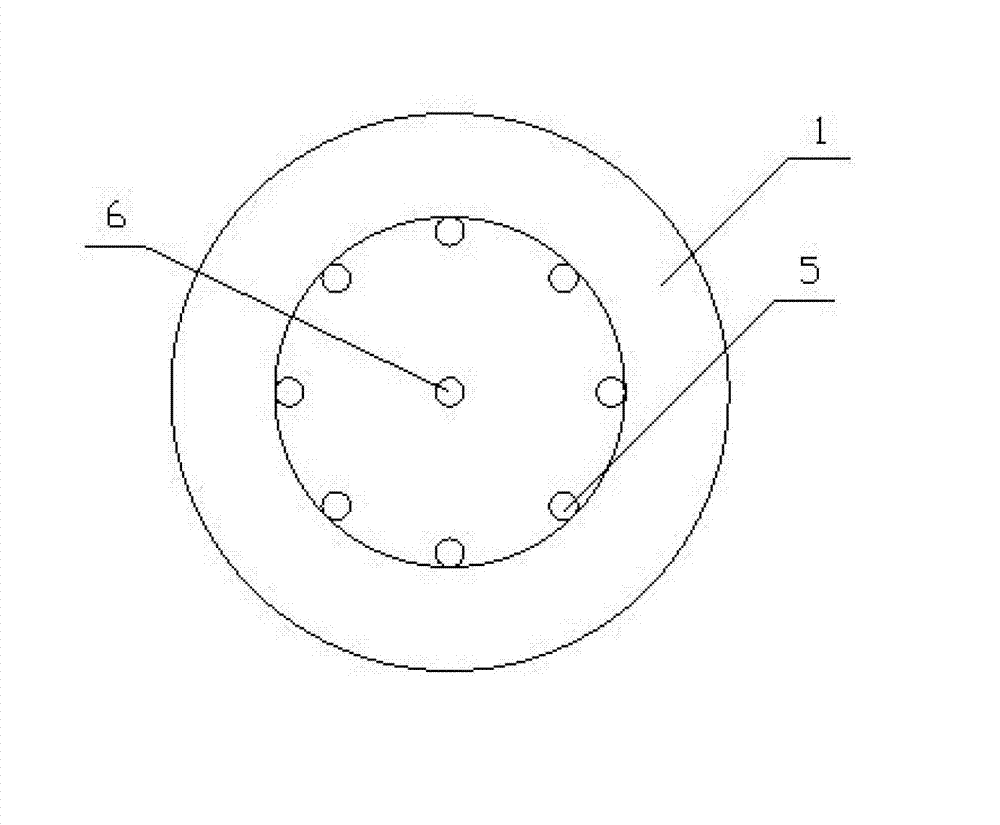

[0016] As shown in the figure: a new type of air-sent agitator, including the air-sent agitator main body 1, the program controller 2 and the fan 3, the bottom middle of the air-sent agitator main body 1 is connected to the program controller 2, and the lower end of the program controller 2 is connected to The fan 3, the main body 1 of the air blower agitator is cylindrical, and the bottom of the air blower agitator main body 1 is provided with a disk 4, and the disk 4 is provided with eight circular blowing pipes 5 and a neutral blowing pipe 6, the neutral blowing pipe 6 is arranged in the middle of the disk 4, and the surrounding air blowing pipe 5 is equidistantly surrounded by the neutral blowing pipe 6. A plurality of blowing nozzles 7 are arranged on the neutral blowing pipe 6 and the surrounding air blowing pipe 5, and the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com