Presses with vision inspection

A visual inspection and stamping machine technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of difficult positioning of printed patterns, increased coil waste rate, and feeding errors, so as to achieve no cumulative error and reduce Small coil waste rate, effect of eliminating errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

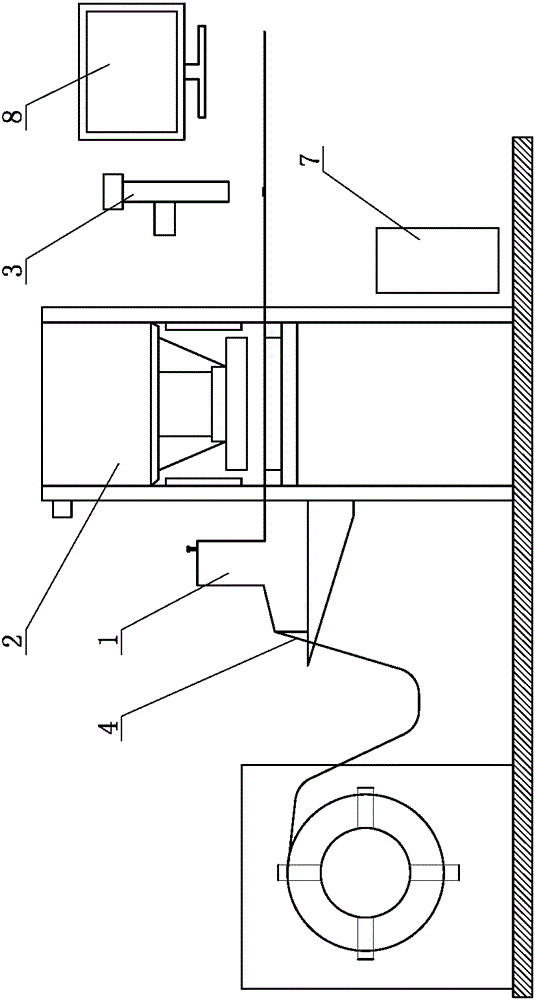

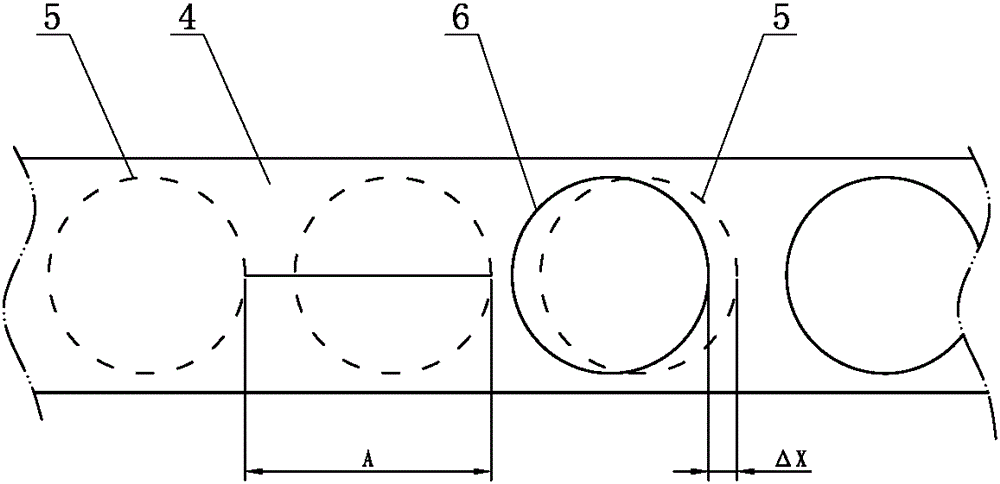

[0023] Such as figure 1 and figure 2 Shown is a first embodiment of a punching machine with visual detection in the present invention, including a feeding mechanism 1, a punching device 2 and an image acquisition device 3, and also includes a feeding controller electrically connected to the feeding mechanism 1, the The image acquisition device 3 is electrically connected to the feed controller, the image acquisition device 3 is located above the coil material 4 on the discharge side of the stamping device 2, and the coil material 4 is provided with a mark reference 5;

[0024] The image acquisition device 3 captures the image of the punched coil material 4 and transmits it to the feed cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com