Automatic feeder used for arc welding

An automatic feed and arc technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of low concentricity accuracy, low preparation, and inability to rotate workpieces to be welded

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

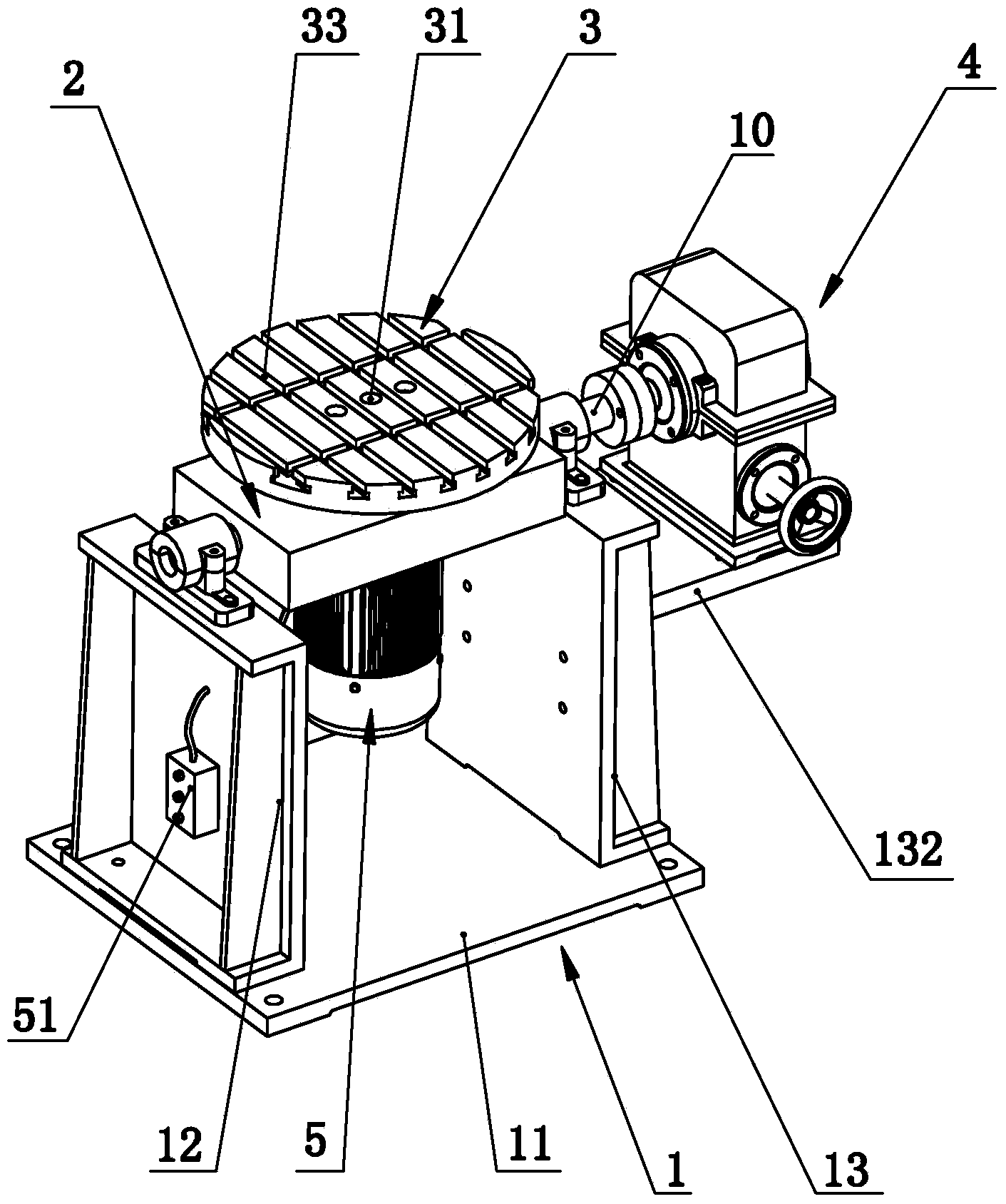

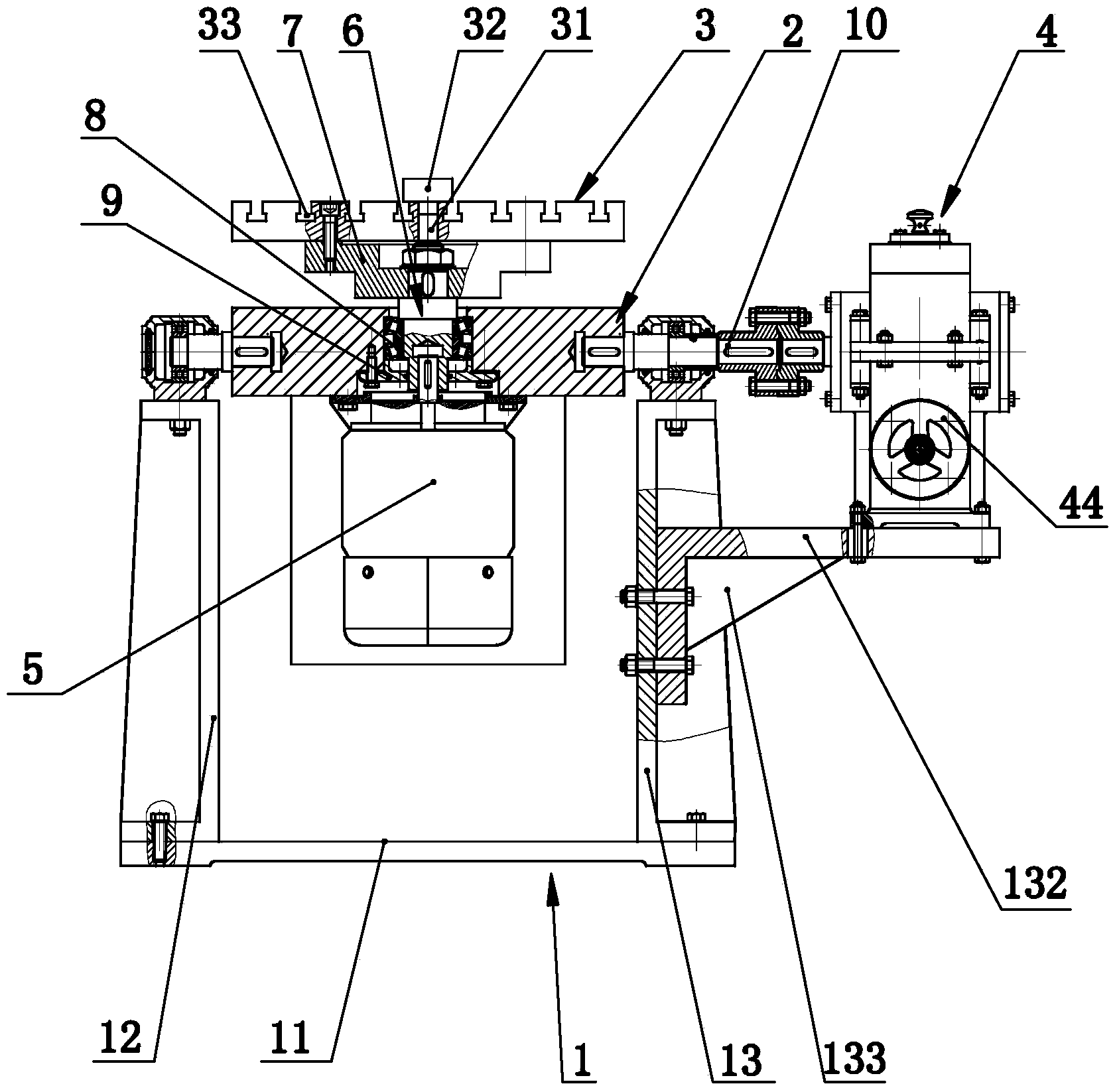

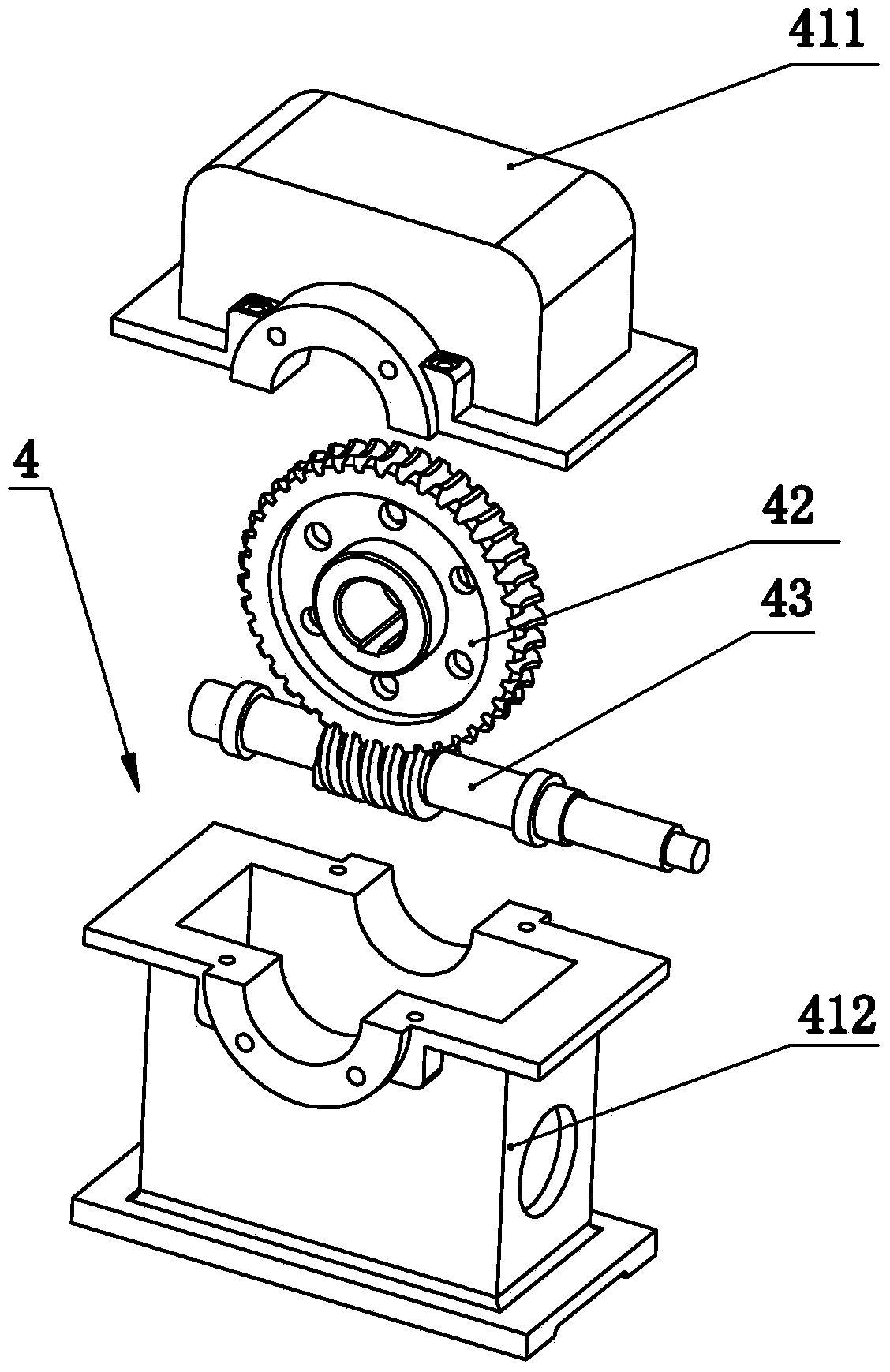

[0025] Such as Figure 1-5 As shown, an automatic feeder for arc welding includes a fixed frame 1 and an overturn table 2, the overturn table 2 is arranged on the fixed frame, and the overturn table 2 is provided with a bracket panel 3 for fixing workpieces, and the overturn table 2 is provided with a turning mechanism 4 for adjusting the turning angle of the turning platform 2, and a motor 5 for driving the rotation of the bracket panel 3 is arranged below the turning platform 2. The output shaft of the turning mechanism 4 is perpendicular to the output shaft of the motor 5. The present invention It also includes a switch 51 to control the operation of the motor. The motor 5 of the present invention is preferably a variable frequency motor. By adopting the above-mentioned technical scheme, the turning mechanism 4 can make the turning table 2 turn over in both directions, that is, adjust the workpiece on the bracket panel 3, so that the workpiece is in the most optimal position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com