Dynamic drive pallet truck and dynamic drive wheel thereof

A technology of electric drive and pallet truck, which is applied in the direction of electric components, electromechanical devices, electrical components, etc., can solve the problems of high starting speed and braking requirements of the driving wheel, complex structure of the braking system, and large volume of the driving structure, and achieve structural Compact size, wide range of transmission ratio, and simplified reduction gear structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

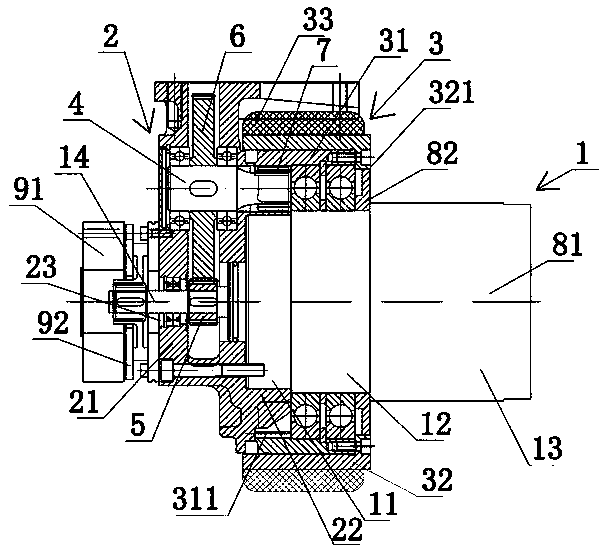

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

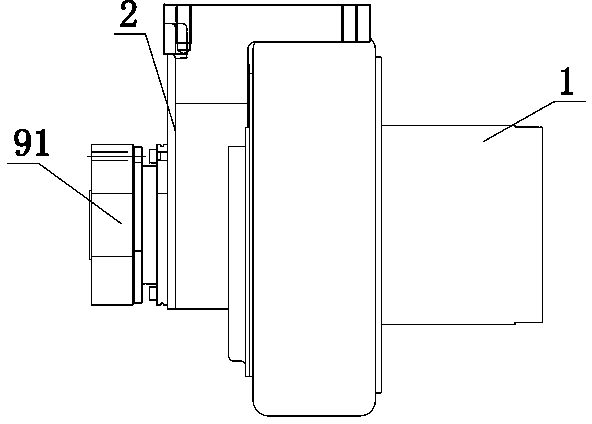

[0021] see Figure 1-Figure 3 , the electric drive pallet truck in this embodiment includes a car body 100, a drive wheel assembly 200 installed on the bottom surface of the car body 100, and an electric control system. The drive wheel assembly 200 includes a drive motor 1, a housing 2, a drive wheel 3, and Drive shaft 4, reduction gear set and electromagnetic brake, reduction gear set includes first driving gear 5, driven gear 6 and second driving gear 7, driving wheel 3 includes mounting ring 31, hub ring 32 arranged in sequence from inside to outside And the outer bead 33, the right end of the hub ring 32 is provided with an extension 321 extending into the cavity of the hub ring 32, the right end surface of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com