Automatic train wheel diameter correcting method

A correction method and a wheel diameter technology, which are applied to railway car body parts, vehicle route interaction equipment, railway signal and safety, etc., can solve the problems of insufficient satellite signal positioning accuracy, unfavorable subway line engineering application, and inability to receive satellite signals. Achieve smooth changes, reduce inaccuracies, and improve stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0033] The present invention provides a kind of train automatic wheel diameter correction method, is suitable for the wheel diameter detection of subway train, and it comprises the following steps:

[0034] (1) Firstly, determine the initial value of the train wheel diameter by measurement. Usually, the initial value of the train wheel diameter is the default value when the train leaves the factory;

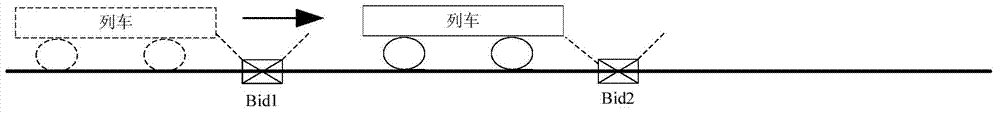

[0035] (2) Arrange the transponders according to the condition of the line and the speed limit of the train, select two adjacent transponders on the straight line as the reference benchmark for wheel diameter correction, and measure the two transponders by means of pull wires...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com