Method for preparing chitosan with ultrahigh deacetylation degree

A technology of deacetylation and chitosan, which is applied in the field of marine chemical engineering, can solve the problems of large amount of alkali, pollute the environment, and high economic cost, and achieve the effect of small molecular weight change, reduce the amount of alkali, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

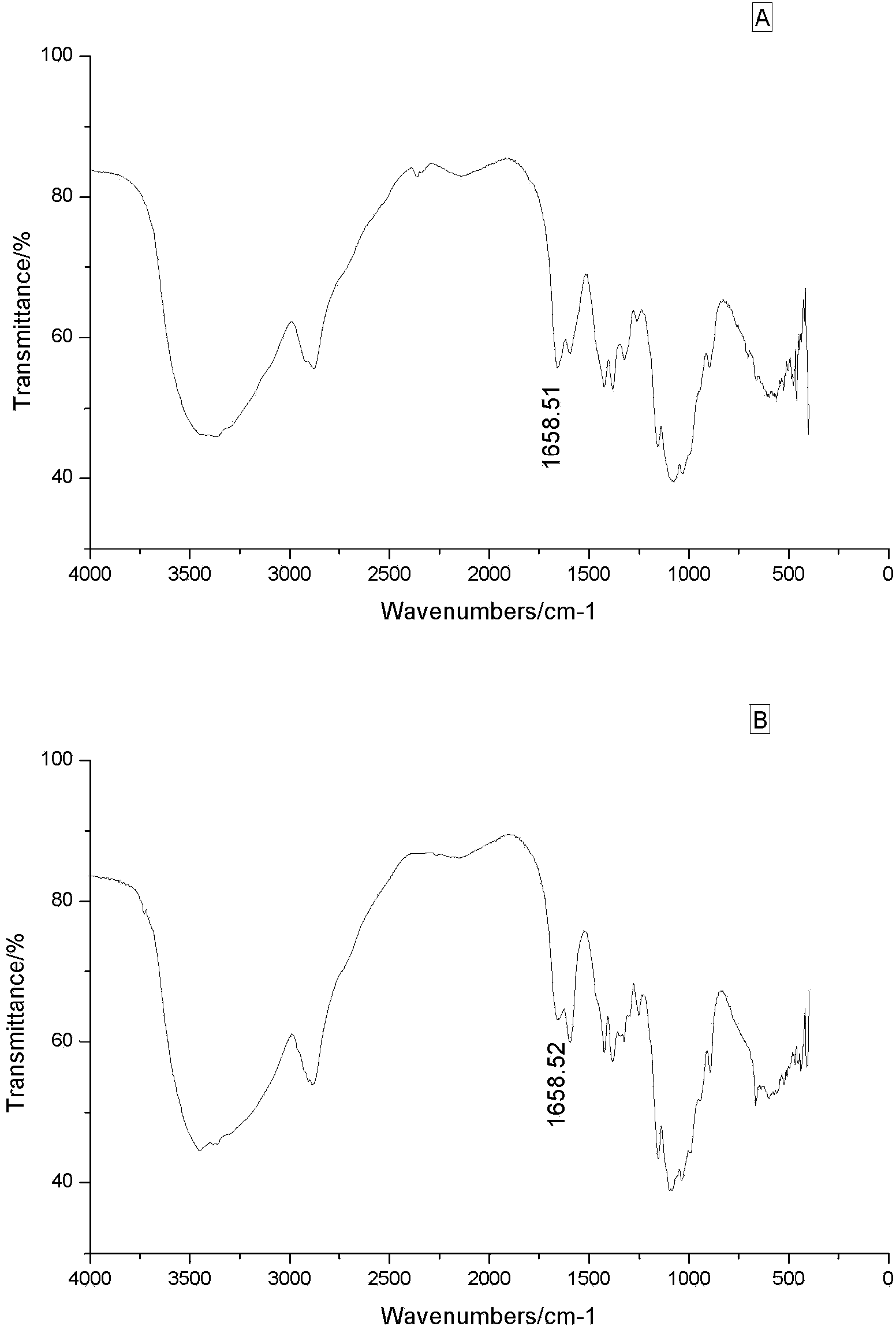

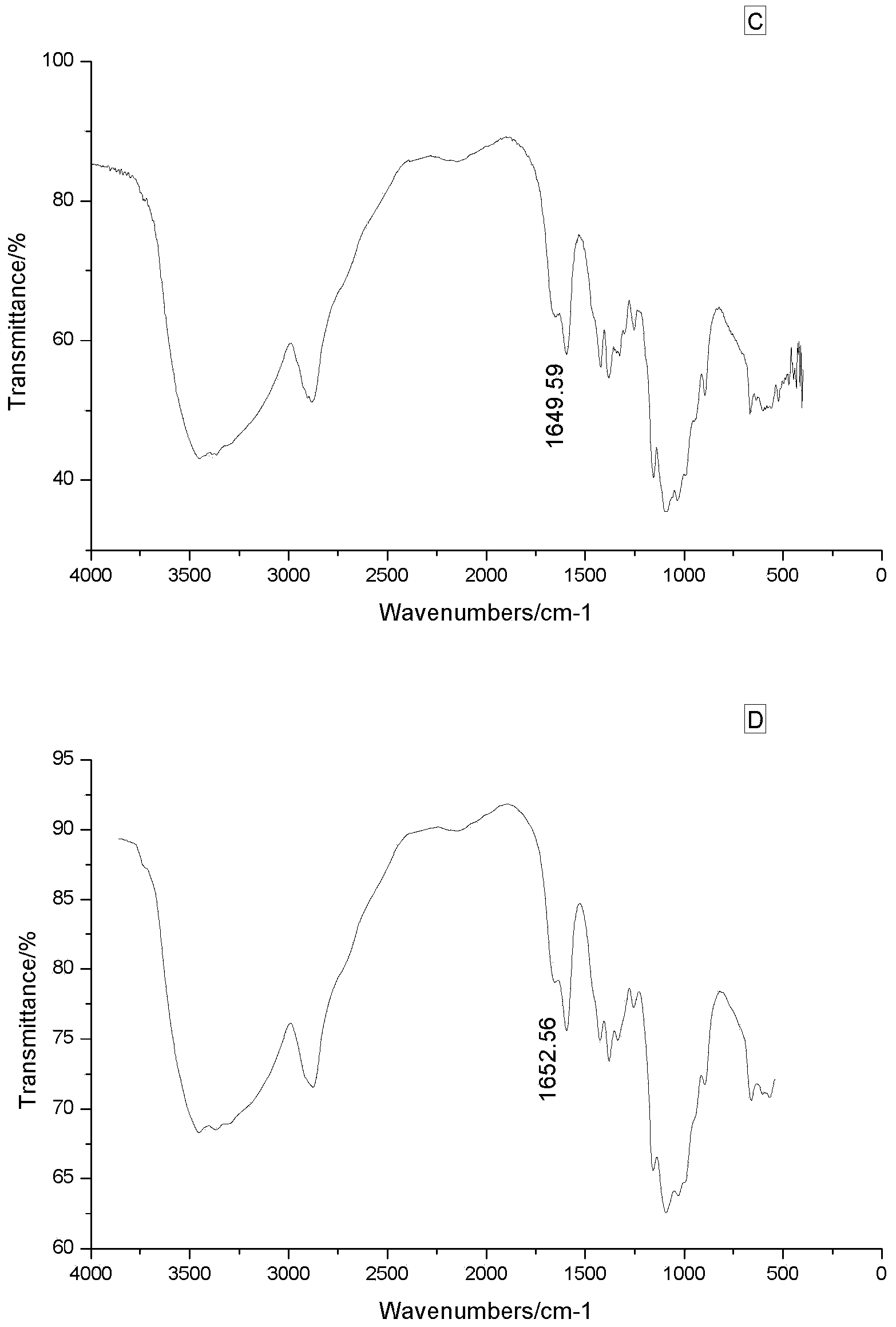

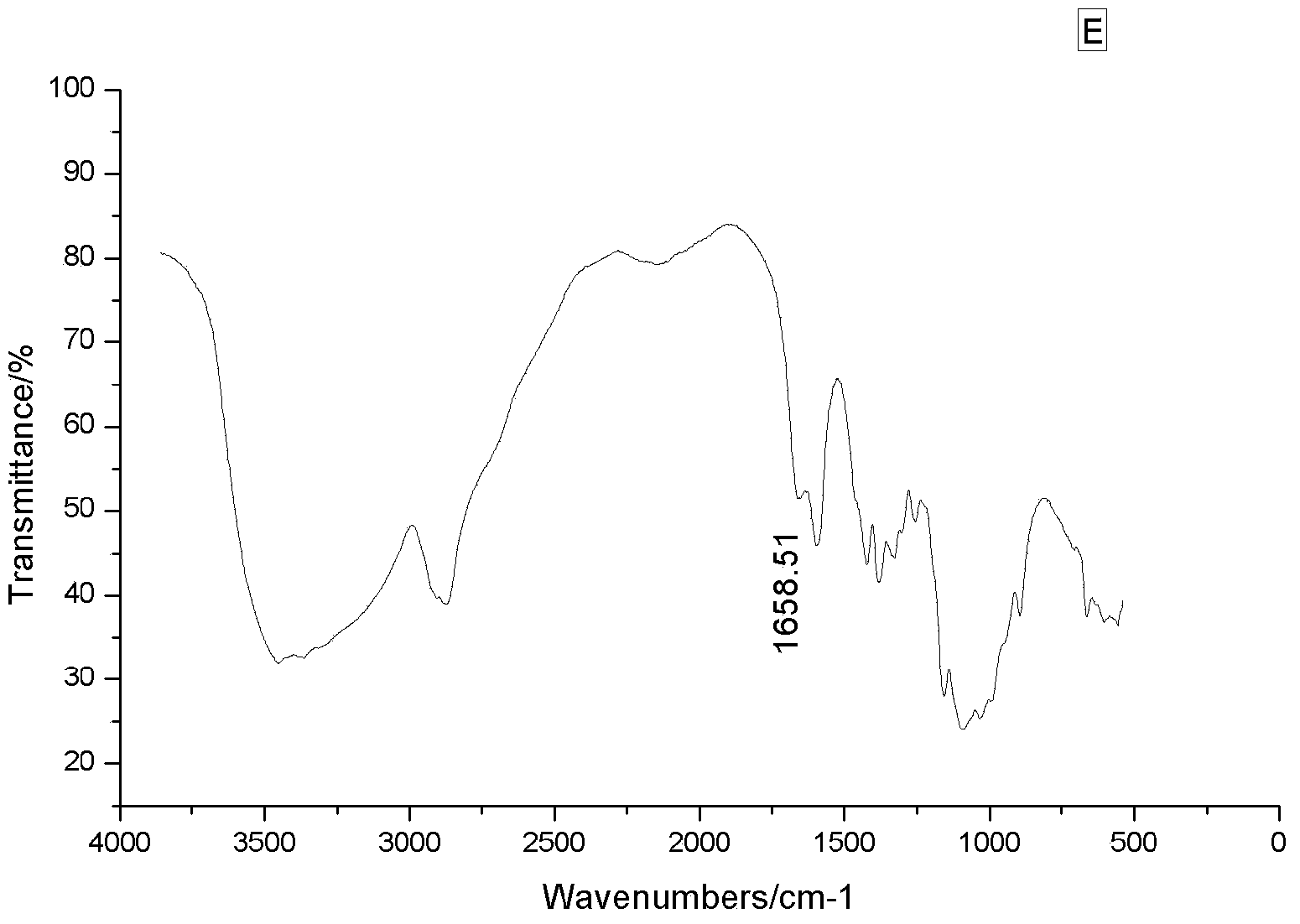

Image

Examples

Embodiment 1

[0019] In sequentially numbered measuring cups, weigh a certain amount of chitosan (the degree of deacetylation is 60%-85%) and NaOH solid, add deionized water and stir rapidly with a glass rod to fully dissolve and mix the two. NaOH dissolves completely with a large exotherm. Place the measuring cup in a vertical pressure steam sterilizer, and set the reaction temperature and reaction time. After the reaction, the chitosan in the measuring cup was washed to neutral with deionized water and suction filtered. After suction filtration, the product was dried in an oven at 105°C to constant weight, the yield was measured, and the weight average molecular weight (Mw) and number average molecular weight (Mn) of chitosan degradation products were analyzed by high performance gel exclusion chromatography . The specific analysis conditions are as follows, chromatographic column: TSK G5000-PWXL; mobile phase: 0.2M acetic acid / 0.1M sodium acetate solution; flow rate: 0.6mL / min; column ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com