A kind of polyurethane/polylactic acid thermoplastic vulcanizate and preparation method thereof

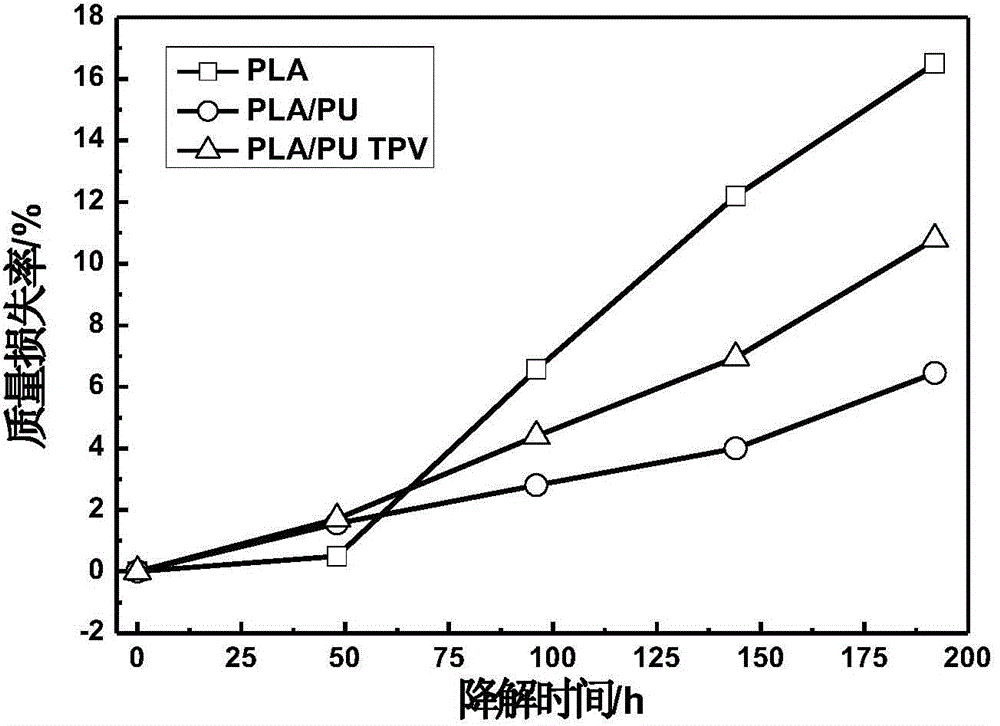

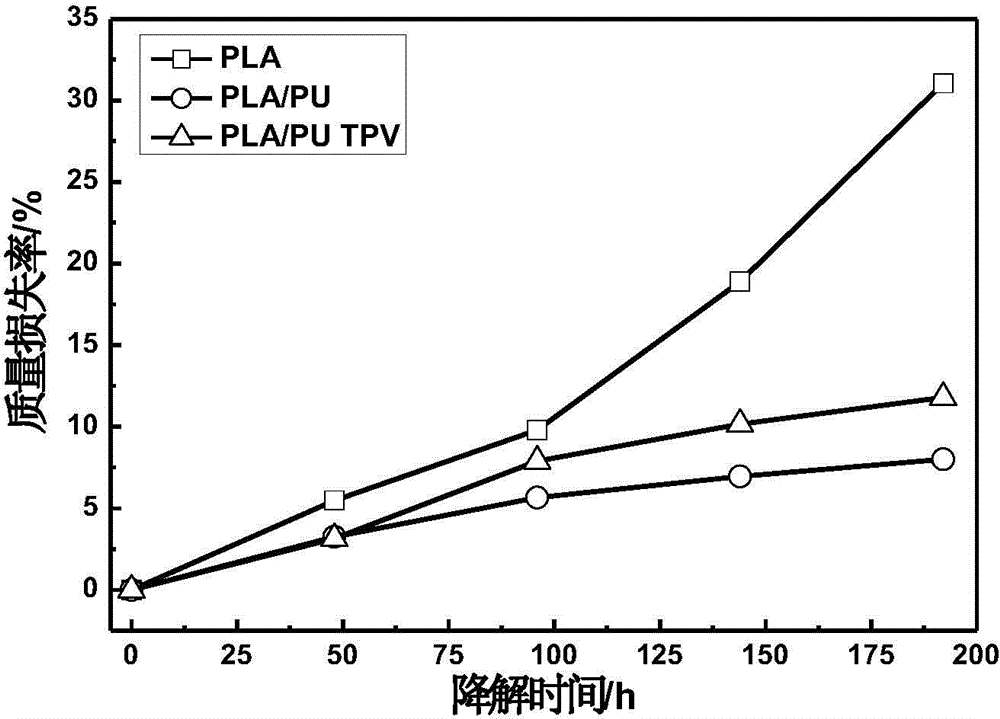

A technology of thermoplastic vulcanizate and polylactic acid, which is applied in the field of polyurethane/polylactic acid thermoplastic vulcanizate, can solve problems such as poor mechanical properties, and achieve the effects of increased mechanical strength, smooth appearance, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] First, melt 80 parts by weight of PLA on a high-temperature open mill at 150°C at room temperature, add 1.5 parts by weight of antioxidant 1010 after covering the rolls; then add 120 parts by weight of PU, mix for 2 minutes, and add 3.0 parts by weight of compatibilizer MDI , kneaded for 2min, prepared the rubber-plastic premix, and released the sheet; on the open mill at room temperature, added 1.8 parts by weight of antioxidant RD and stearic acid of 1.2 parts by weight, kneaded for 2min, finally added 3.6 parts by weight of DCP, and mixed Mixed evenly; put the mixed sample into an internal mixer with a rotation speed of 100rpm and a mold cavity temperature of 150°C for dynamic vulcanization. The time is 10min. See Table 1.

Embodiment 2

[0049] The formulation components and dosage, process conditions and process flow are the same as in Example 1, except that the dosage of compatibilizer MDI is 4.0 parts by weight, and the performance test is shown in Table 1.

Embodiment 3

[0051] The formulation ingredients and dosage, process conditions and process flow are the same as in Example 1, except that the dosage of compatibilizer MDI is 5.0 parts by weight, and the performance test is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com