Disperse black dye composition, disperse dye and its preparation method and application

A dye composition and disperse dye technology, applied in the direction of dyeing, organic dyes, textiles and papermaking, etc., can solve the problems of general sublimation fastness, etc., and achieve the effect of low staining and high sublimation fastness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] On the other hand, the present application also provides a preparation method of the disperse dye described in the present application, which is characterized in that it comprises: mixing the components contained in the disperse black dye composition described in the present application according to the stated ratio to prepare Disperse black dye composition, which is ground (micronized) in the presence of auxiliary materials, optionally dried, preferably spray-dried;

[0048] Alternatively, each component contained in the disperse black dye composition described in this application is ground separately in the presence of auxiliary materials, then mixed according to the stated ratio, and optionally dried, preferably spray-dried.

[0049] The disperse black dye composition of the present application or its components can be liquid or paste after grinding (micronization), and can be powder or granular after drying (preferably spray drying).

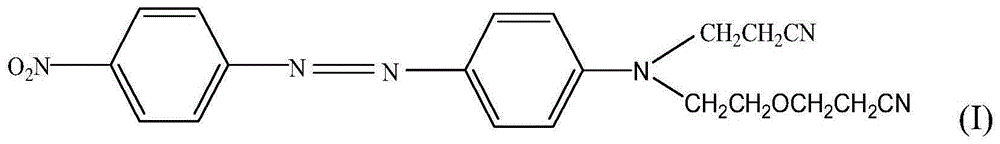

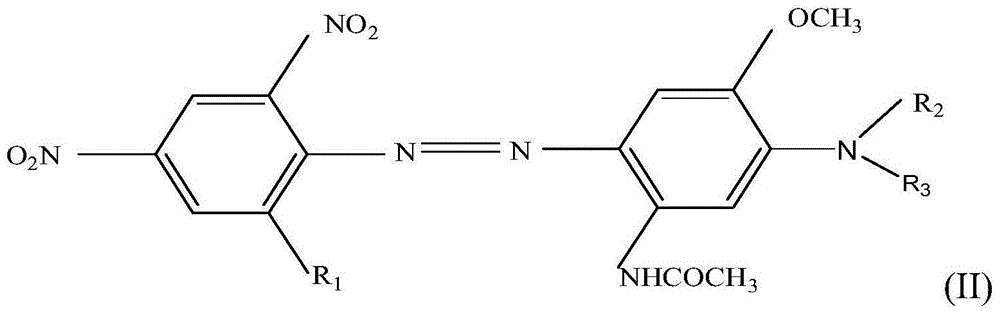

[0050]In another aspect, the p...

Embodiment

[0054] The present application will be further described below in conjunction with the examples, but the protection scope of the present application is not limited thereto.

[0055] In the embodiment, the component A, component B and component C of the present application are mixed with dispersant MF, diffusing agent NNO, diffusing agent CNF or sodium lignosulfonate 85A or 83A in a certain ratio, and then used Grinding and dispersing by sand milling to make slurry, and further spray drying to make disperse dyes.

[0056] The above-mentioned dye components are all known dye compounds and are commercially available. Dispersant MF, diffusing agent NNO, diffusing agent CNF, sodium lignosulfonate 85A and 83A are all known auxiliaries and can be purchased in the market.

[0057] Examples 1-16 Mix component A, component B, component C, additives and water according to the ratio shown in Table 1, grind and spray dry to prepare disperse dyes.

[0058] Table 1

[0059]

Embodiment 1

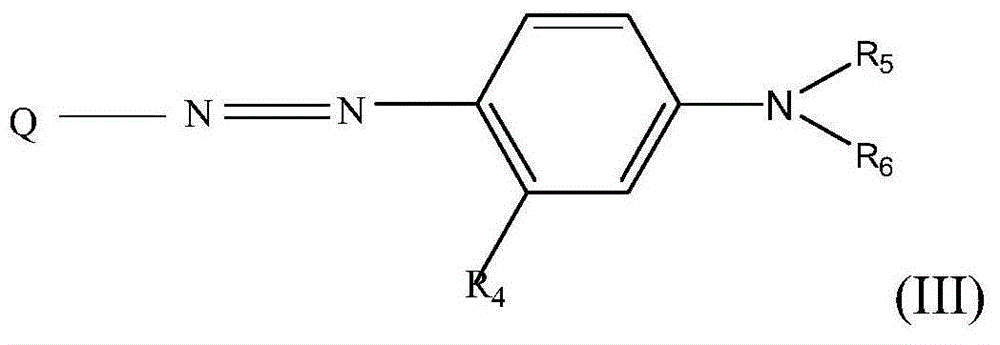

[0065] Take 43g of the compound of the following formula (III-1), 22g of the compound of the following formula (4), 1g of the compound of the following formula (5), mix and grind with 41.5g of lignin MF and 161g of water, and spray dry to prepare a disperse dye.

[0066]

[0067]

[0068] Use respectively 0.1g of the disperse dyes prepared in Examples 1-16 and Comparative Examples 1-2, mix with 10g of polyester ammonia and 99.9g of water, adjust the pH of the dye bath to 5 with acetic acid, and heat up to 5 in 35 minutes. 210°C, keep warm for 30 minutes, cool to 80°C, take it out, dye according to GB / T2394-2006 standard to obtain black textile material, and then carry out setting treatment at 190°C for 45 seconds. Using GB / T5718-1997 to measure its sublimation fastness, the results are as follows.

[0069] Table 2

[0070] Examples or comparative examples to which disperse dyes belong

[0071] It can be seen from the results that the sublimation fastness of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com