Adhesive used for semiconductor wafer cutting

A technology of adhesives and semiconductors, applied in the direction of adhesives, adhesive additives, epoxy resin glue, etc., can solve the problems of many bright edges, high defective rate, and high chip drop rate, and achieve easy degumming, good toughness, and improved The effect of excellent product rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

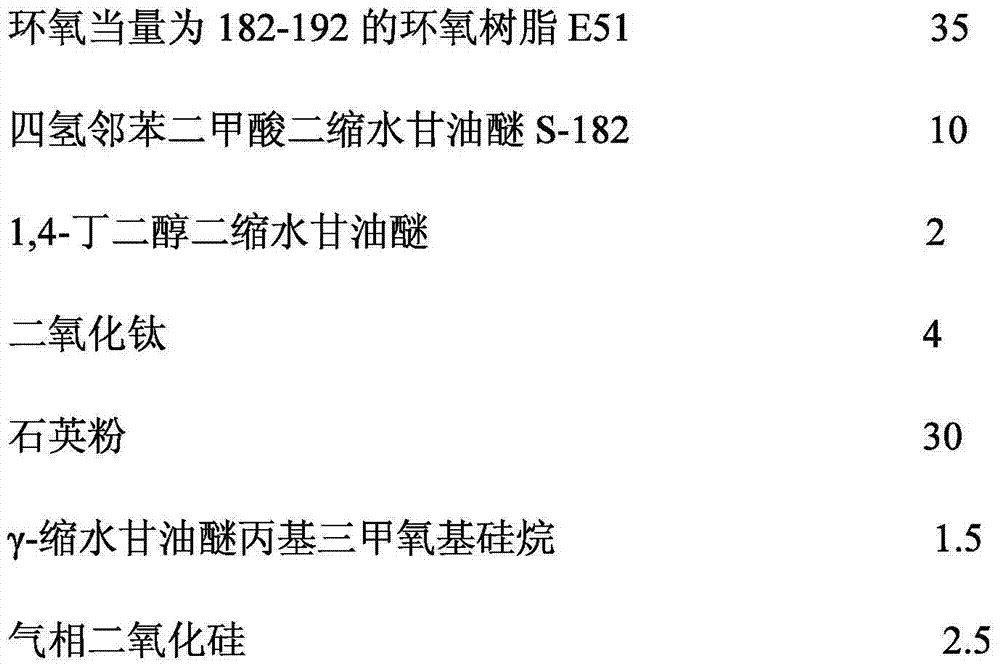

[0016] A kind of adhesive that is used for semiconductor wafer dicing, comprises resin component and curing agent component, and wherein resin component is made up of the raw material of following weight component:

[0017]

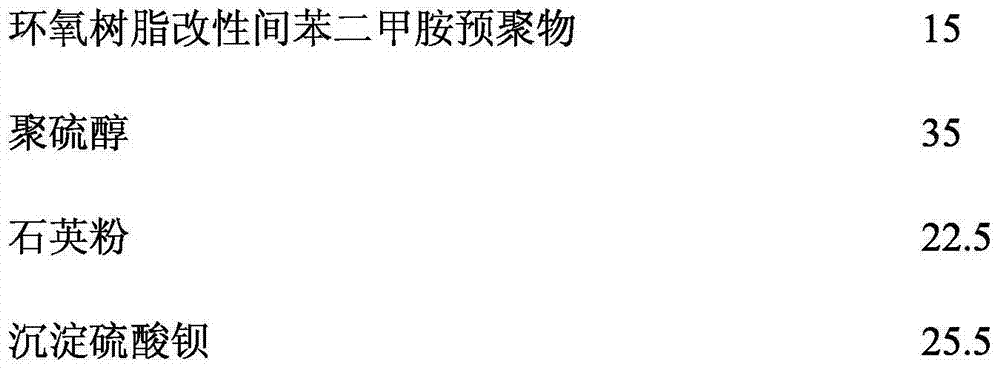

[0018] Curing agent component has the weight parts composition of following component:

[0019]

[0020]

[0021] Wherein the epoxy resin modified m-xylylenediamine prepolymer is made up of the parts by weight of the following components:

[0022] m-Xylylenediamine 75

[0023] 2,4,6-tris(dimethylaminomethyl)phenol 1.5 with gas chemical grade K54

[0024] Epoxy resin E51 23.5

[0025] Prepared by the following method:

[0026] Step 1, prepare the resin component: E51, diglycidyl tetrahydrophthalate S-182, 1,4 -Butanediol diglycidyl ester, titanium dioxide, quartz powder, γ-glycidyl ether propyl trimethoxysilane, and gas phase titanium dioxide are dispersed and ground by a three-roll machine, and degassed by a vacuum bubble machine, and then th...

Embodiment 2

[0031] A kind of adhesive that is used for semiconductor wafer dicing, comprises resin component and curing agent component, and wherein resin component is made up of the weight part of following component:

[0032]

[0033] Curing agent component has the weight parts composition of following component:

[0034]

[0035]

[0036] Wherein the epoxy resin modified m-xylylenediamine prepolymer is made up of the parts by weight of the following components:

[0037] m-Xylylenediamine 75

[0038] 2,4,6-tris(dimethylaminomethyl)phenol 1.5 with gas chemical grade K54

[0039] Epoxy resin E51 23.5

[0040] The preparation method is as follows:

[0041] Step 1, preparation of the resin component: take by weight the epoxy resin E51, diglycidyl tetrahydrophthalate S- 182. Hexahydrophthalic acid diglycidyl ether S-184, 1,4-butanediol diglycidyl ester, titanium dioxide, quartz powder, γ-glycidyl ether propyl trimethoxysilane, gas-phase titanium dioxide after dispersion It is g...

Embodiment 3

[0046] A kind of adhesive that is used for semiconductor wafer dicing, comprises resin component and curing agent component, and wherein resin component is made up of the weight part of following component:

[0047]

[0048] Curing agent component has the weight parts composition of following component:

[0049]

[0050]Wherein the epoxy resin modified m-xylylenediamine prepolymer is made up of the parts by weight of the following components:

[0051] m-Xylylenediamine 75

[0052] 2,4,6-tris(dimethylaminomethyl)phenol 1.5 with gas chemical grade K54

[0053] Epoxy resin E51 23.5

[0054] The preparation method is as follows:

[0055] Step 1, preparation of the resin component: take by weight the epoxy resin E51, diglycidyl tetrahydrophthalate S- 182. Hexahydrophthalic acid diglycidyl ether S-184, 1,4-butanediol diglycidyl ester, titanium dioxide, quartz powder, precipitated barium sulfate, γ-glycidyl ether propyl trimethoxysilane, gas phase After the titanium dioxid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com