Method for extracting mixed aromatics from lubricating base oil

A technology for lubricating base oil and mixed aromatic hydrocarbons, which is used in lubricating compositions, petroleum industry, refined hydrocarbon oil, etc., can solve the problems of complicated operation and low extraction efficiency, and achieves simple process, reduced separation time, and easy operation and control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

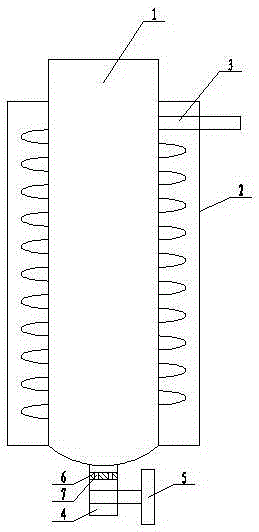

Image

Examples

Embodiment 1

[0014] The method for extracting mixed aromatics from lubricating oil base oil comprises the following steps: selecting silica gel as a separation medium, filling silica gel into a glass cup with heating function, selecting furfural and mixing lubricating oil base oil in a ratio of 1:4 ; Then pour the mixture into a glass cup and let it stand to separate the lubricating oil base oil. The standing time: 10 minutes, the extraction temperature is maintained at 50°C, the mixed aromatics and the lubricating base oil are separated, and the mixed aromatics content is 4.9%.

Embodiment 2

[0016] The method for extracting mixed aromatics from lubricating oil base oil comprises the steps of: selecting silica gel as a separator

[0017] Isolate the medium, put silica gel into the inside of the glass with heating function, select furfural and lubricating oil base oil to mix at a ratio of 1:8; then pour the mixture into the glass and let it stand to separate the lubricating oil base oil for a period of time : 30min, the extraction temperature was maintained at 60°C, the mixed aromatics and the lubricating base oil were separated, and the mixed aromatics content was obtained by extraction at 5.0%.

Embodiment 3

[0019] The method for extracting mixed aromatics from lubricating oil base oil comprises the following steps: selecting silica gel as a separation medium, filling silica gel into a glass cup with heating function, selecting furfural and mixing lubricating oil base oil in a ratio of 1:10 ; Then pour the mixture into a glass cup and let it stand to separate the lubricating oil base oil. The standing time: 50min, the extraction temperature is maintained at 70°C, the mixed aromatics and the lubricating base oil are separated, and the mixed aromatics content is 5.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com