A kind of high toughness plastic mold steel and its production method

A technology of plastic mold steel and production method, which is applied to high-toughness plastic mold steel and its production field, can solve the problems of large fluctuation of hardness, many processes, and limitation of practical use performance, and achieves good hardness uniformity and fine grain size. the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

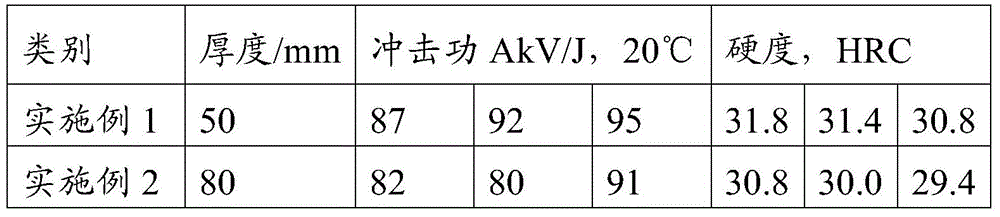

Embodiment 1

[0037] The chemical composition of the high-toughness plastic mold steel according to Example 1 is C0.37, Si0.28, Mn0.90, Cr1.83, Mo0.35, S≤0.015, P≤0.015, Als: 0.023, and the rest For Fe and unavoidable impurities.

[0038] The production method of the high-toughness plastic mold steel according to Example 1 includes slab heating, controlled rolling, slow cooling of the steel plate, normalizing, and tempering. The size of continuous casting slab is: 250~300mm×2200mm×3100mm.

[0039] In Example 1, the slab was heated to 1200° C. at a heating rate of 6.5 min / cm. After descaling by high-pressure water, it is rolled on a double-stand four-high reversible wide and thick plate rolling mill, and the steel plate is turned into steel before the rough rolling mill. The ratio of the thickness of the intermediate billet to the thickness of the finished product is 2.5 times, and the starting temperature of the finish rolling is 890°C. After rolling, the steel plate is slowly cooled, an...

Embodiment 2

[0042] The chemical composition of the high-toughness plastic mold steel according to Example 2 is C0.37, Si0.28, Mn0.90, Cr1.80, Mo0.37, S≤0.015, P≤0.015, Als: 0.030, and the rest For Fe and unavoidable impurities.

[0043] The production method of the high-toughness plastic mold steel according to Example 2 includes slab heating, controlled rolling, slow cooling of the steel plate, normalizing, and tempering. The size of continuous casting slab is: 250~300mm×2200mm×3100mm.

[0044]In Example 2, the slab was heated to 1220° C. at a heating rate of 6.5 min / cm. After descaling by high-pressure water, it is rolled on a double-stand four-high reversible wide and thick plate rolling mill, and the steel plate is turned into steel before the rough rolling mill. The ratio of the thickness of the intermediate billet to the thickness of the finished product is 2 times, and the starting temperature of the finish rolling is 850°C. After rolling, the steel plate is slowly cooled, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com