85kg to 120kg sapphire crystal growth automatic control method

A sapphire crystal, automatic control technology, applied in crystal growth, single crystal growth, single crystal growth, etc., can solve problems such as low production efficiency of unit personnel, difficult sapphire crystal growth, long crystal production process, etc., to save manpower and material resources, Save labor costs and improve product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

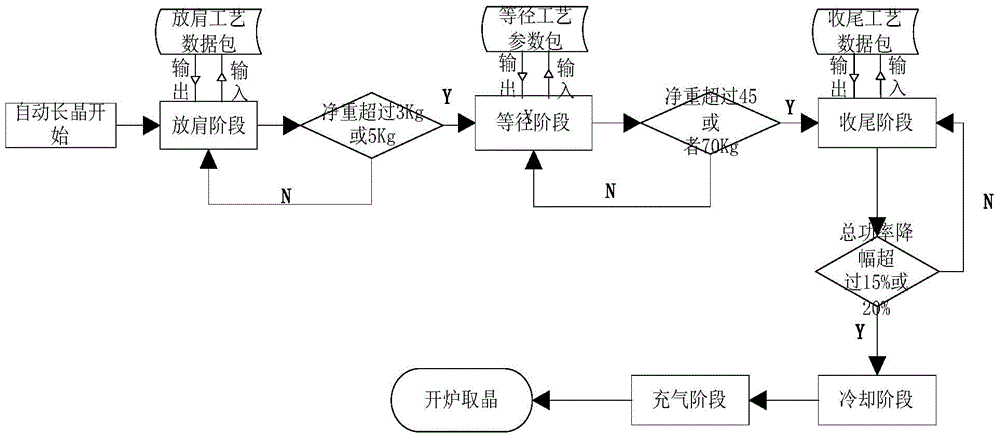

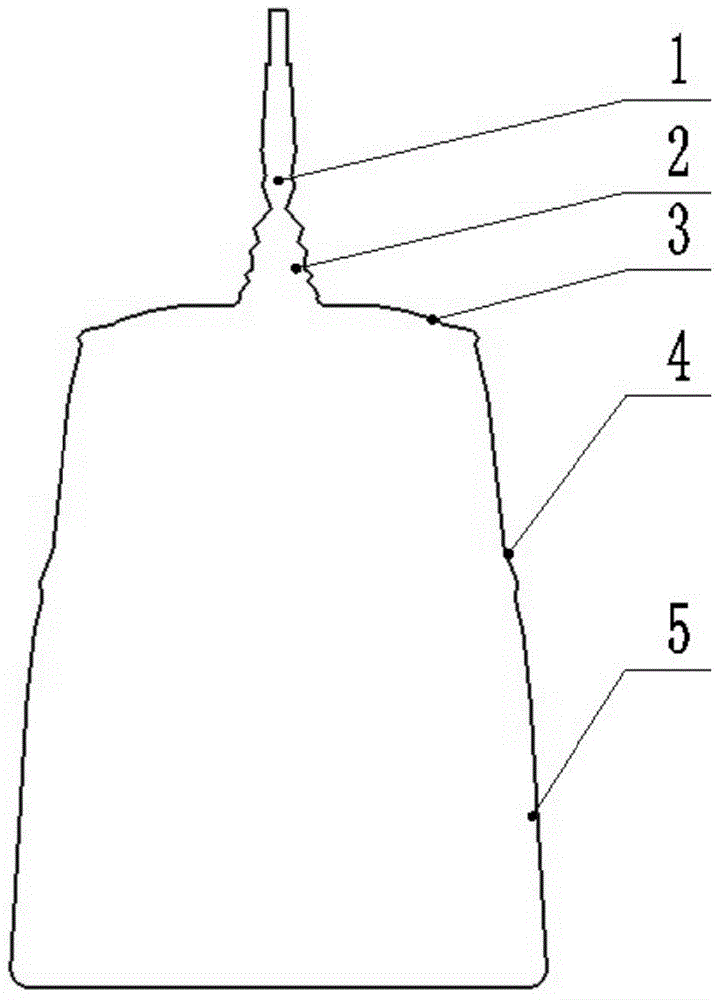

[0029] Such as figure 1 with figure 2 As shown, the present invention discloses an automatic control method for sapphire crystal growth from 85kg to 120kg. According to the crystal growth rate, the present invention automatically adjusts the directional heat transfer within the thermal field through a certain algorithm to complete the automatic control technology for crystal production, which is characterized by: In the entire crystal production process, except for the manual loading and unloading and seeding, all other processes such as shoulder setting, equal diameter, finishing, cooling and inflation are all automatically run by the computer in sequence. After the seeding is completed, the shoulder setting process is divided into 5 stages according to weight, and the corresponding growth rate is set for different stages. The actual measured rate is compared with the rate value of each stage through PLC, and the temperature drop rate is adjusted through PID. After the PLC me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com