Steel ladder cage installation structure and installation method

A technology for installing structures and steel ladders, which is applied to building structures, on-site preparation of building components, construction, etc., can solve the problems of inconvenient disassembly and assembly of steel ladder cages, poor operation safety, etc., and saves welding and de-soldering time. , to ensure safety, to facilitate the effect of installation and dismantling work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The steel ladder cage installation structure and installation method of the present invention will be further described in detail below.

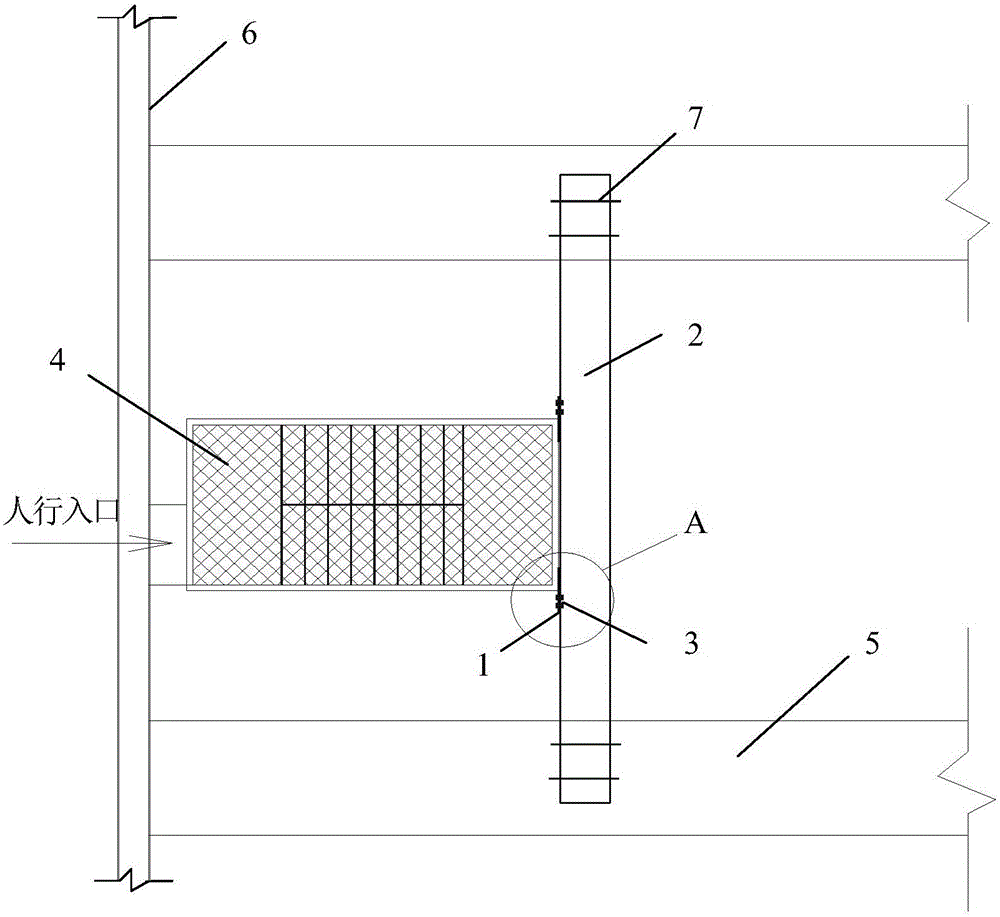

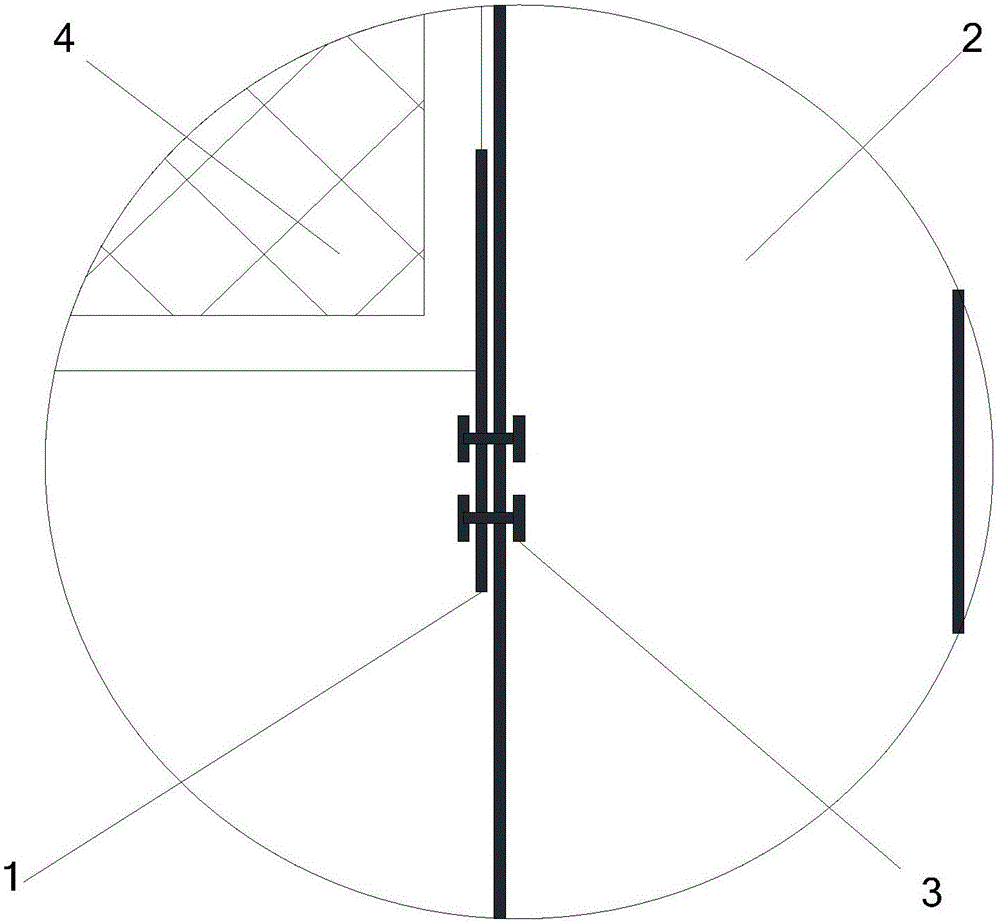

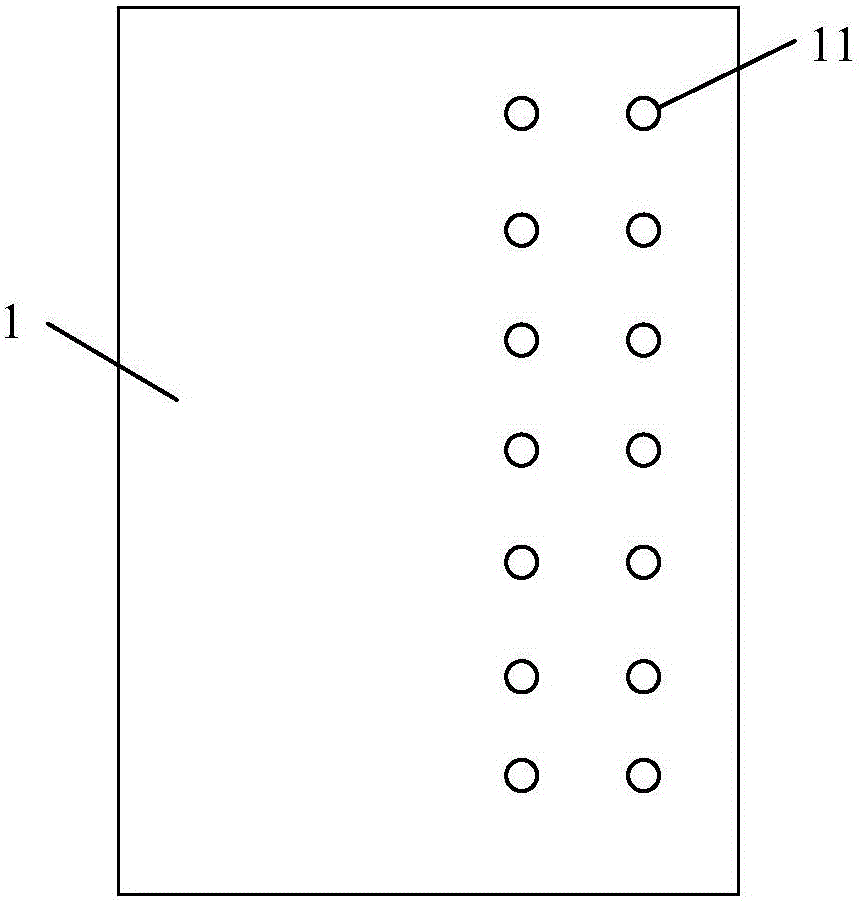

[0033] see Figure 1 to Figure 4 , this embodiment provides a steel ladder cage installation structure, including two steel plates 1, a section steel 2 and a number of fastening components 3, the two steel plates 1 are fixedly arranged (this embodiment adopts welding method) on the steel The two wings on the side of the first cage body 41 of the ladder cage 4 opposite to the entrance side (that is, the pedestrian entrance side), that is to say, the side of the first cage body 41 of the steel ladder cage 4 is the entrance side, A simple walkway 9 is provided on the entrance side, and construction workers enter the steel ladder cage 4 through the simple walkway 9 through the entrance side. The two steel plates 1 are correspondingly provided with several rows of first connection holes 11 arranged at intervals along the height direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com