Ultra-high-pressure axial plunger pump

A technology of axial piston pump and ultra-high pressure, which is applied in the direction of pumps, liquid variable displacement machines, machines/engines, etc., and can solve difficult problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

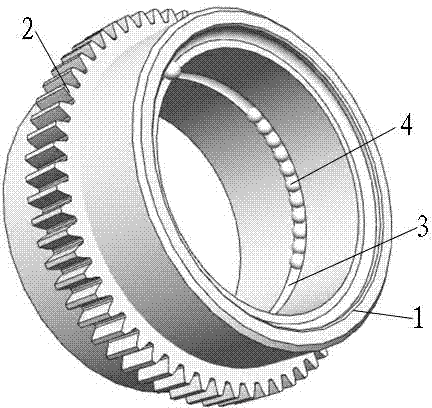

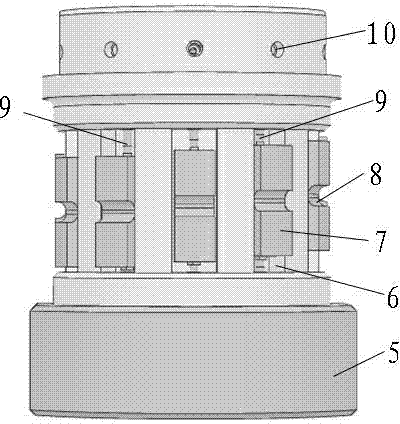

[0033] Example 1, such as figure 1 with figure 2 As shown, the ultra-high pressure axial piston pump of the present invention includes a cylindrical pump body 5; several strip-shaped sliding holes 6 are evenly distributed on the circumferential wall of the pump body 5, wherein each sliding hole 6 is arranged There is a slide block 7 that can slide relatively, and the two ends of the slide block 7 are respectively connected with a small plunger pump 9, and the small plunger pump 9 is placed in the wall at both ends of the sliding hole 6 on the pump body 5, so that Both ends of the pump body 5 are provided with an oil inlet and an oil outlet corresponding to the small plunger pump 9; a spinning drive mechanism driven by a motor 21 is provided inside or outside the pump body 5, The spinning driving mechanism cooperates with the slider 7 in the pump body 5 or outside the pump body 5, so that the rotation of the spinning driving mechanism can drive the slider 7 to slide axially i...

Embodiment 2

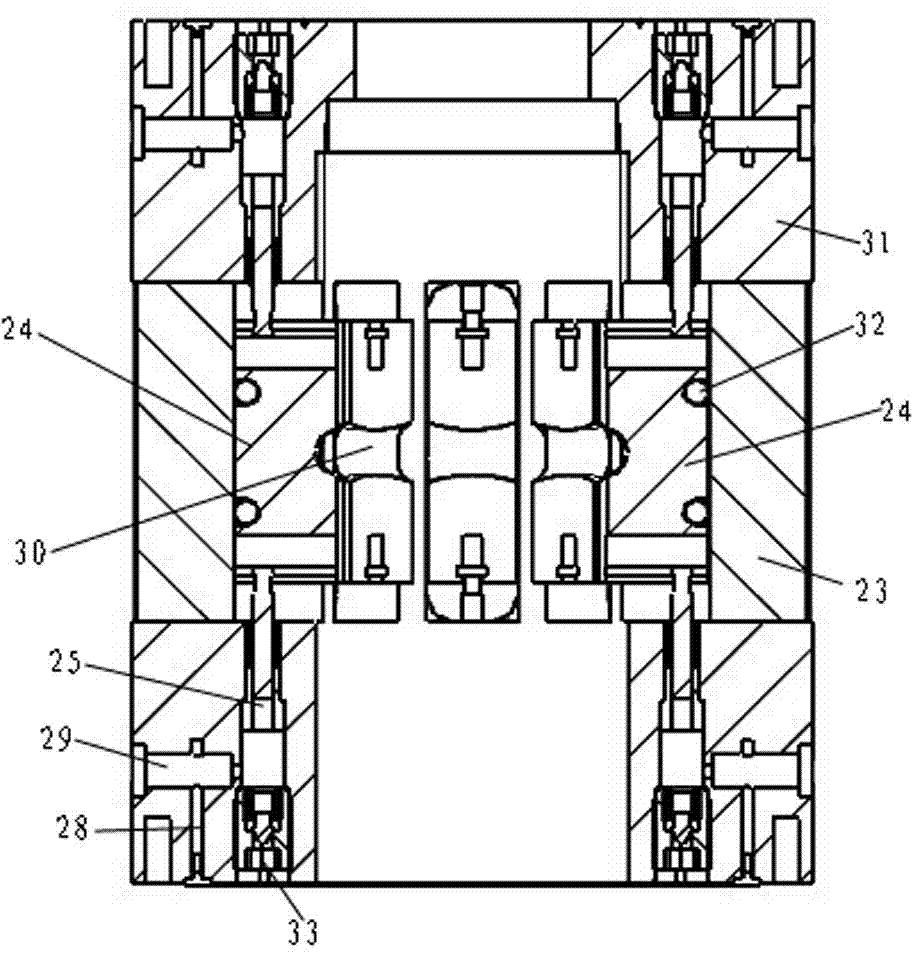

[0035] Example 2 as image 3 with Figure 4 As shown, the ultra-high pressure axial piston pump of the present invention includes a cylindrical pump body 26; a number of elongated sliding holes 6 are evenly distributed on the circumferential wall of the pump body 26, wherein each sliding hole 6 is arranged There is a slide block 24 that can slide relatively, and the two ends of the slide block 24 are respectively connected with a small plunger pump 25, and the small plunger pump 25 is placed in the wall at both ends of the sliding hole 6 on the pump body 26, so that Both ends of the pump body 26 are provided with an oil inlet and an oil outlet corresponding to the small plunger pump 25; a spinning drive mechanism driven by a motor 21 is provided inside or outside the pump body 26, The spinning drive mechanism cooperates with the slider 24 in the pump body 26 or outside the pump body 26, so that the rotation of the spinning drive mechanism can drive the slider 24 to slide axia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com