Self-compensating emergency combination seal for nuclear reactor main circulation pump sealing device

A main circulation pump and sealing device technology, which is applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve problems such as threats to personal and property safety, decreased sealing performance, leakage of high-temperature radiation media, etc., to prevent nuclear media from leaking, The effect of protecting personal and property safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

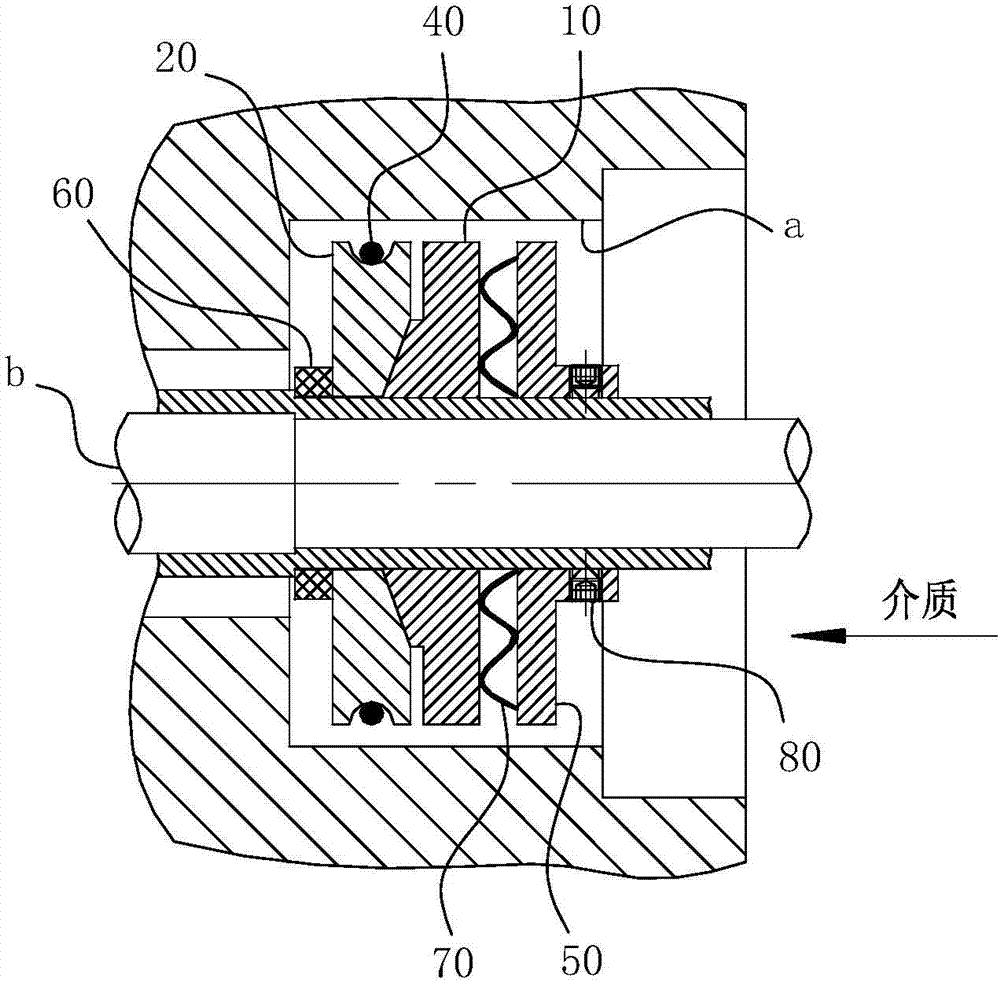

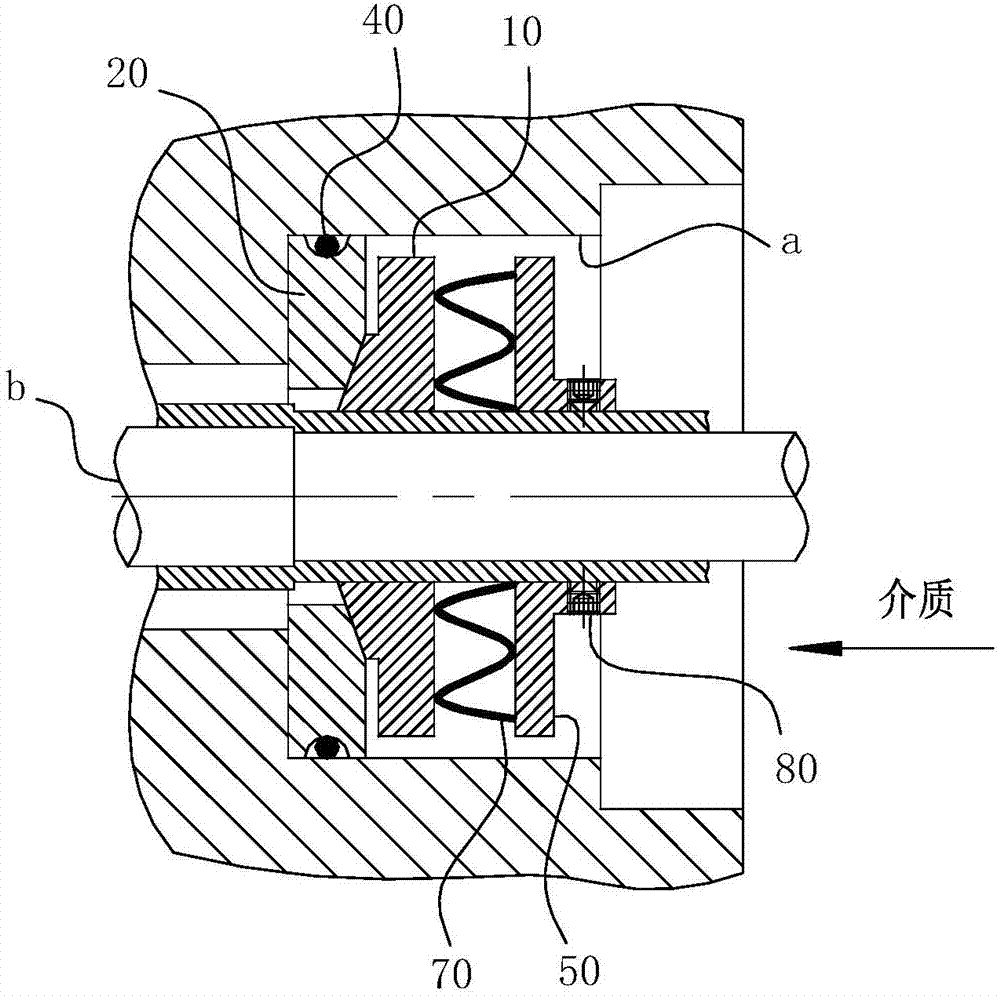

[0031] For ease of understanding, combined here Figure 1-6 Concrete structure and workflow of the present invention are described as follows:

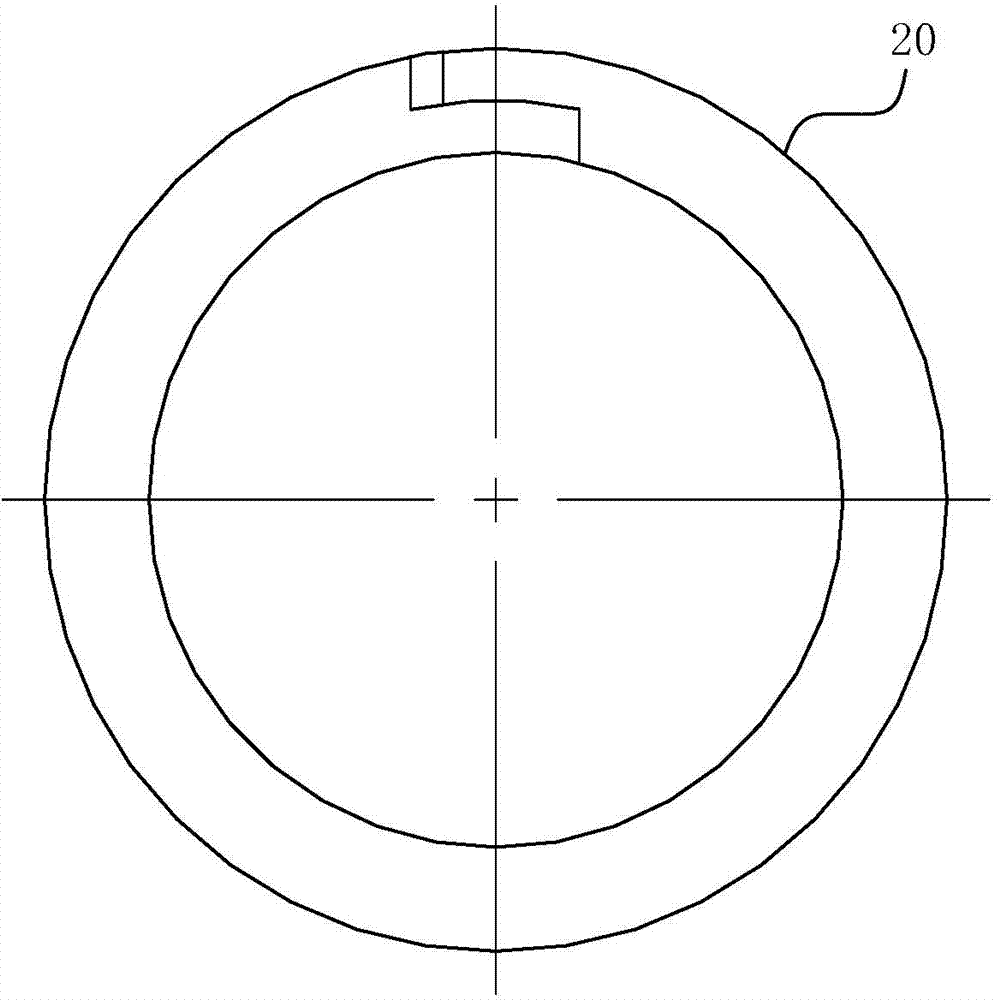

[0032] see figure 1 , the specific embodiment of the present invention is to arrange retaining rings 60, lap-type The sealing ring (that is, the movable part 20), the compensation ring (that is, the heat-resistant ring 10), the wave spring 70, the support ring 50, and the tension spring 40 with the hot-melt connecting piece 30 are tightly hooped on the lap seal. on the ring. Under the normal operating conditions of the system, that is, when the medium temperature is lower than 80°C, each component rotates with the main shaft b, and the medium flows from the high-pressure side to the low-pressure side through the gap between the lap seal ring and the cylinder a. When the system breaks down and stops, the temperature of the medium rises sharply, and the hot-melt connecting piece 30 on the retaining ring 60 and the tension spring 40 e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com