A lock slag and lock bucket valve with purging and flushing device for coal chemical industry

A flushing device and coal chemical technology, which is applied in the field of ball valves and valves, can solve problems such as flow channel perforation, valve seal failure, and failure, and achieve the effects of improving surface hardness, prolonging service life, and improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

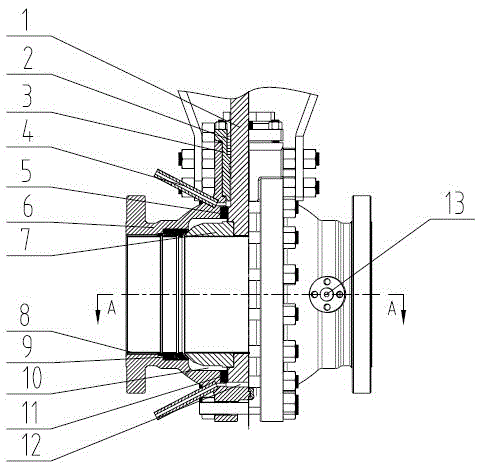

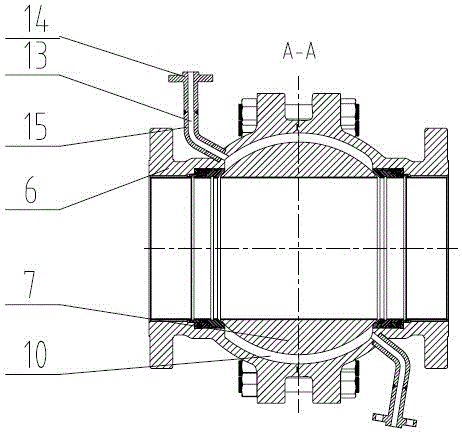

[0018] Such as figure 1 , 2 As shown, a lock slag and lock bucket valve with purge and flushing device for coal chemical industry, including valve body 6, ball 7, valve stem 1, valve seat 9, valve body bushing 8, packing 2, packing gland 3. The ball 7 is installed inside the valve body 6, a valve body cavity 10 is formed between the two, the ball 7 and the valve seat 9 form a sealing pair, the valve stem 1 passes through the upper part of the valve body 6, runs through the ball 7, and the lower end extends into the valve body 6 In the lower blind hole 12, the valve stem 1 is welded to the sphere 7, and the shaft journal of the valve stem 1 is equipped with an upper bearing sleeve 5 to cooperate with the valve body 6, and the valve stem 1 is located in the valve body 6. The inner portion of the blind hole 12 is provided with a lower bearing sleeve 11 Cooperate with the valve body 6, the valve stem 1 is located between the upper part of the upper bearing sleeve 5 and the valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com