Wireless linkage type torque sensor

A torque sensor and linkage technology, applied in the field of torque online dynamic monitoring, can solve the problem of inability to measure the output torque, and achieve the effect of simple structure, convenient monitoring, and avoiding limitations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

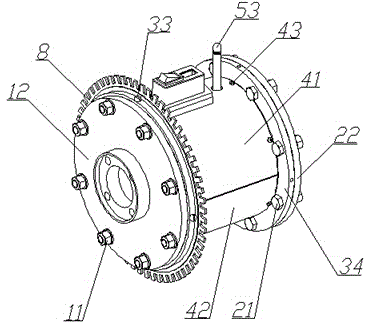

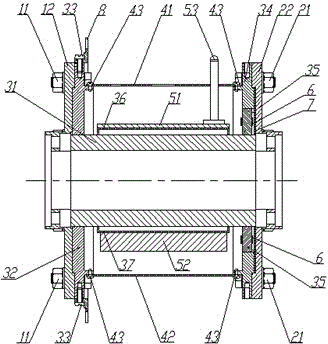

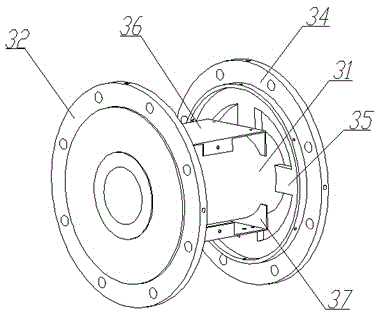

[0030] The following is combined with the specific attachment figure 1 Attached image 3 The present invention is further explained, but the protection scope of the present invention should not be limited by this.

[0031] Reference attachment figure 1 Attached image 3 , The wireless linkage torque sensor provided by the present invention includes: main body part 3, left flange part 1, right flange part 2, cover 4, built-in circuit part 5, strain gauge 6, baffle 7 , Speed measuring code plate 8; The main body component 3 includes a main barrel 31, a left twist plate 32, a fastening screw 33, a right twist plate 34, an elastic body 35, a circuit board mounting base 36, and a power supply mounting base 37; The left flange part 1 includes a left flange 12 and a connecting bolt set 11; the right flange part 2 includes a right flange 22 and a connecting bolt set 21; the cover 4 includes an upper cover 41 and a lower cover 42. Phillips screw 43; the built-in circuit component 5 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com