Adaptive sealing test device applicable to multi-product special-shaped cavities

A self-adaptive sealing and testing device technology, which is applied in the direction of liquid tightness measurement using liquid/vacuum degree, etc., can solve the problem that the distance between the edge of the cavity and the socket end cannot be tested, it is difficult to realize the shared test of multiple products, and the leakage of test results Large volume and other problems, to achieve the effect of improving test efficiency, test accuracy, and connection reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

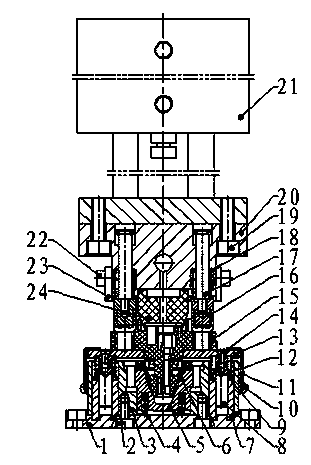

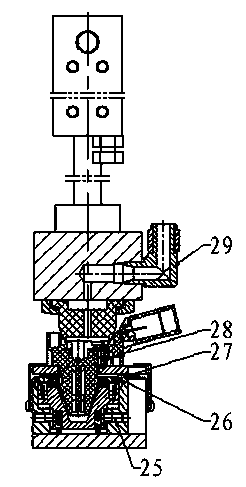

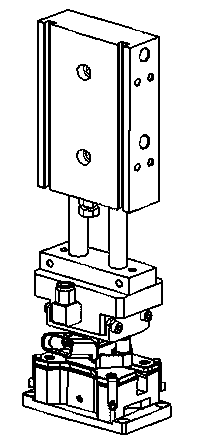

[0028] Below in conjunction with accompanying drawing, the present invention will be further described:

[0029] Such as Figure 1-7 As shown, a self-adaptive sealing test device for multi-product special-shaped cavities includes a lower part of the device installed on a platform and an upper part of the device installed on a fixed base. The lower part of the device includes a bottom plate 1 on which a first The screw 2 fixes the hollow seat 3, the hollow seat 3 is equipped with a core seat 5, and an anti-rotation screw 25 is installed between the hollow seat 3 and the core seat 5, which can effectively prevent the core seat 5 from rotating and affect the test. The core seat 5 The bottom is equipped with spring I 4, under the effect of spring I 4, the core seat 5 can move up and down in the hollow seat 3, and the top of the core seat 5 is equipped with a seal ring, which can be a large seal ring 6 or a small seal ring. The sealing ring 30 and the pressing ring 26 are locked o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com