Solid-solid phase transition rate measurement device and method for solid material

A solid-state material and measurement device technology, applied in the investigation phase/state change and other directions, can solve problems such as large errors in test results, easily damaged samples, and measurement results are easily affected by the environment, and achieve the effect of real-time observation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

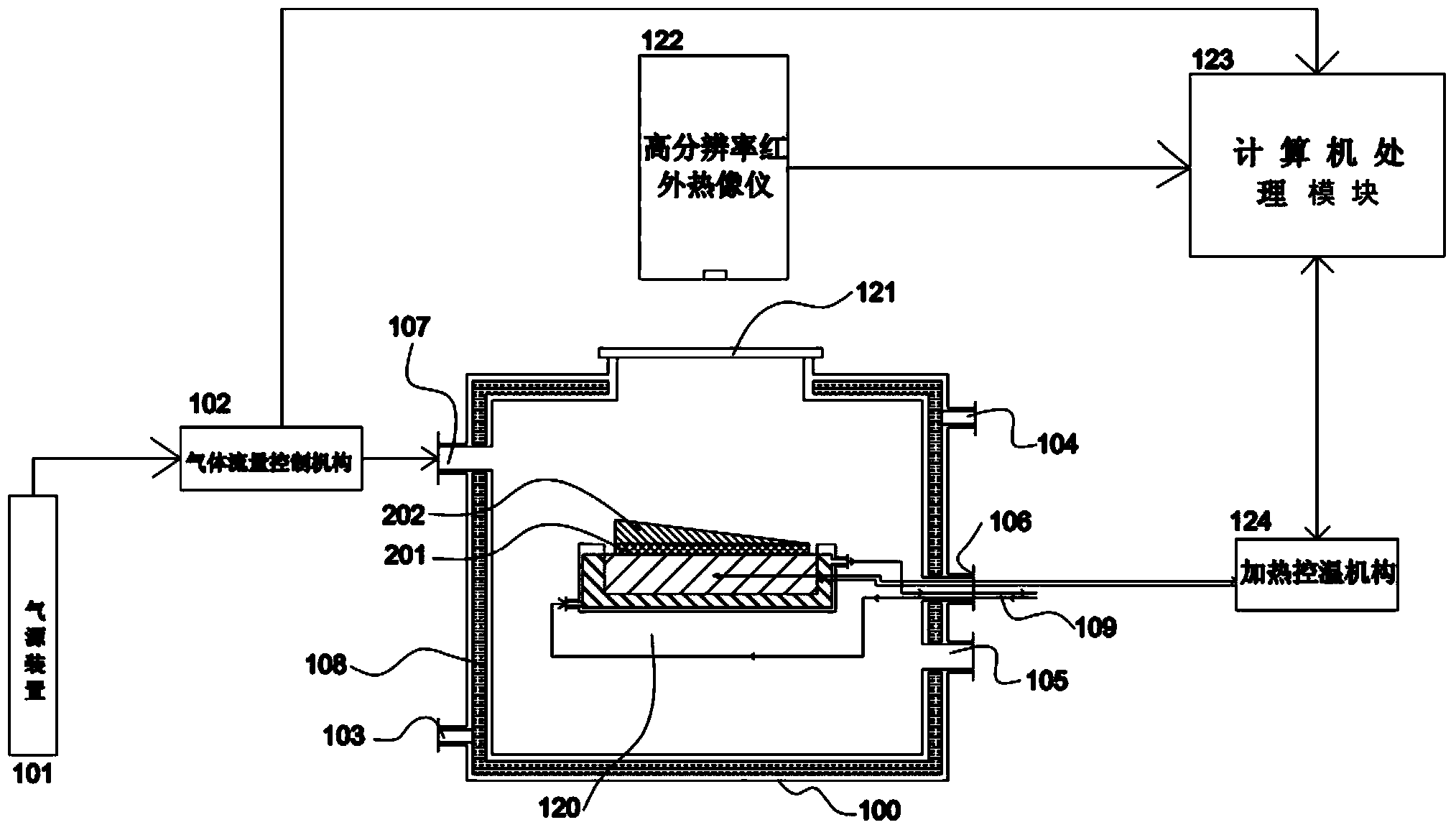

[0030] The phase change rate measuring device of the solid-solid phase change material of the present invention is mainly composed of a high-resolution high-speed infrared thermal imager 122, a computer processing module 123, a heating temperature control mechanism 124, a vacuum heating chamber 100, a gas flow control mechanism 102, a gas source device 101 and so on.

[0031] The present invention includes a vacuum heating chamber 100, which is connected with a gas source device 101, the vacuum heating chamber 100 is a double-layer water cooling structure, a circulating water pipe 108 is arranged in the chamber wall of the vacuum heating chamber 100, and a vacuum heating chamber 100 is provided with The circulating water inlet 103 and the circulating water outlet 104, the water enters the spiral circulating water pipe 108 through the circulati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com