Method for testing specific heat capacity of lithium ion battery

A lithium-ion battery and testing method technology, applied in the field of specific heat capacity of lithium-ion batteries, can solve the problems of inability to obtain specific heat capacity changes, high test costs, and inability to conduct specific heat tests for large-scale batteries, and achieve low test costs, simple and convenient implementation, and Wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below, the substantive features and advantages of the present invention will be further described in conjunction with examples, but the present invention is not limited to the listed examples.

[0034] The present invention will be described in detail below by taking 1C rate discharge as an example, and the other rate discharge methods are the same.

[0035] The present invention is realized through the following steps:

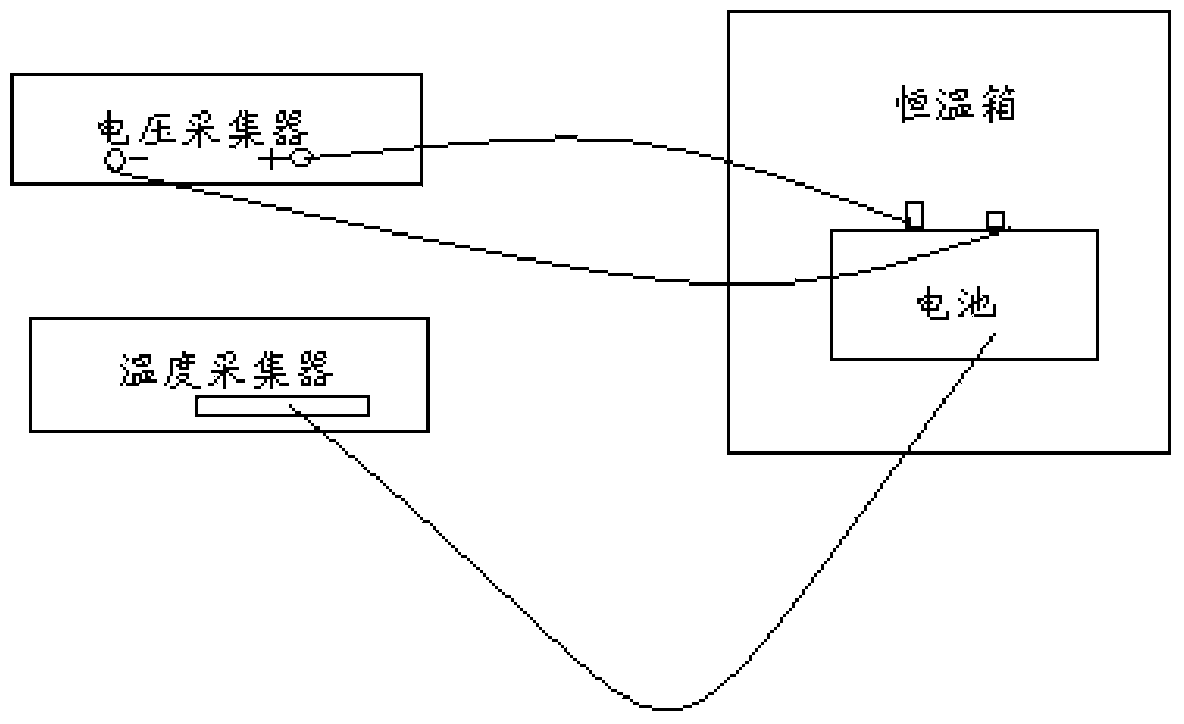

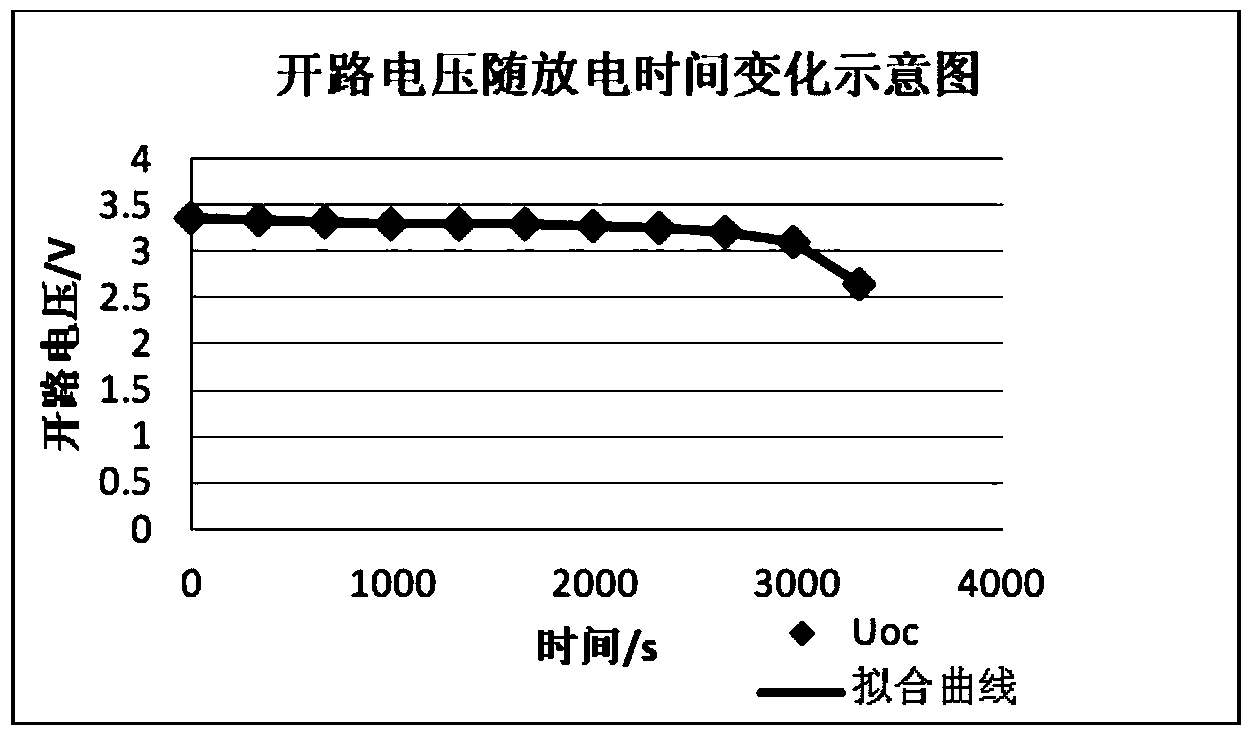

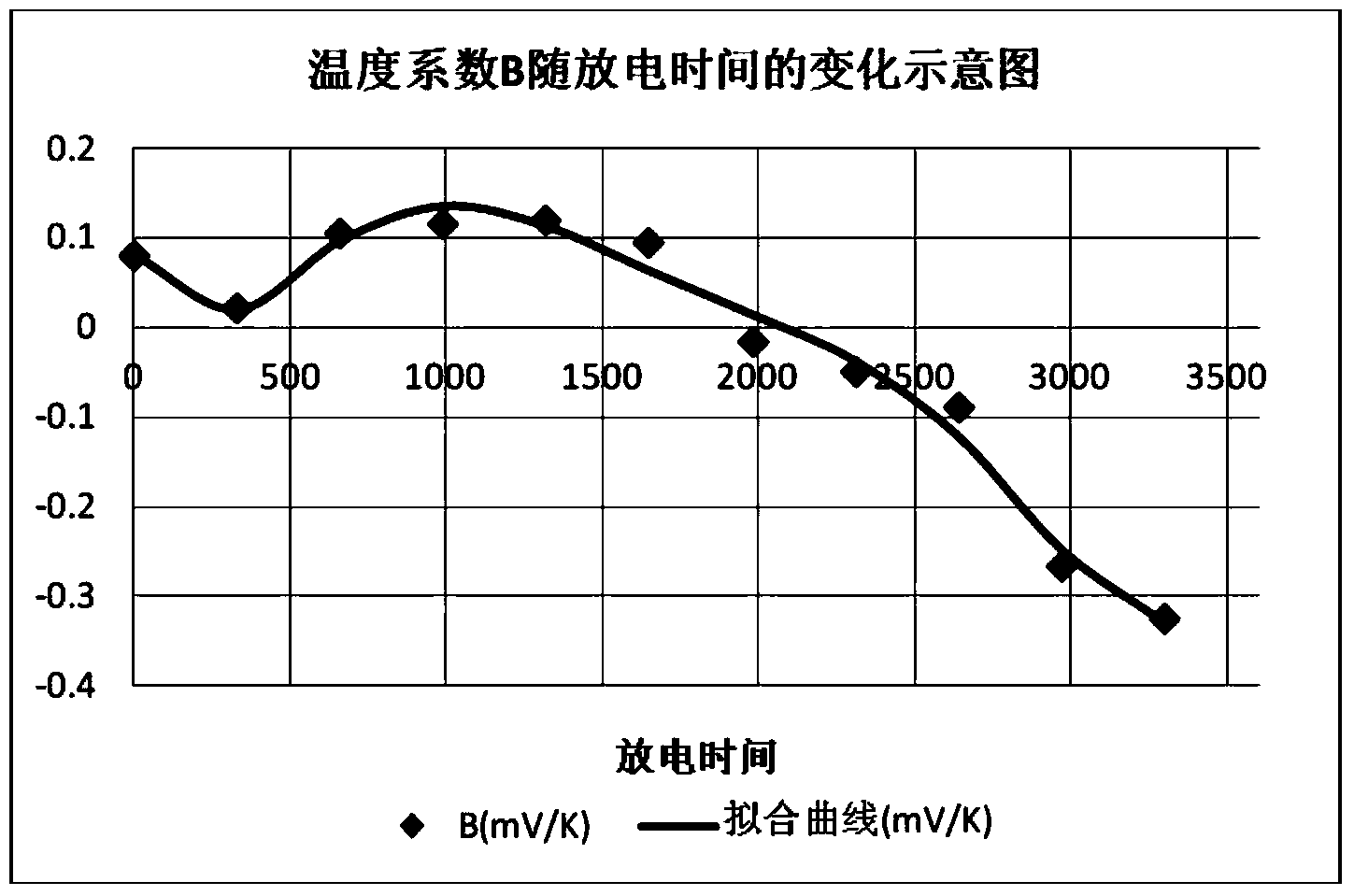

[0036] Step 1: Measure and record the open circuit voltage and surface temperature of the battery under different SOC states until the battery SOC=0, and perform regression analysis on the data of the battery open circuit voltage changing with the surface temperature under different SOC states to obtain the open circuit voltage of the battery u oc , The fitting relationship between the open circuit voltage temperature coefficient B and different discharge time t;

[0037] u oc =a 0 +a 1 *t+a 2 *t 2 +a 3 *t 3 +...+a f *t f Fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com