Method for evaluating soundness of high-MgO cement

A technology of stability and cement, applied in the field of evaluating the stability of high MgO cement, can solve the problem of inability to accurately evaluate the stability of high MgO cement, and achieve the effect of simple operation and stable reaction process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with specific examples, but not as a limitation of the present invention.

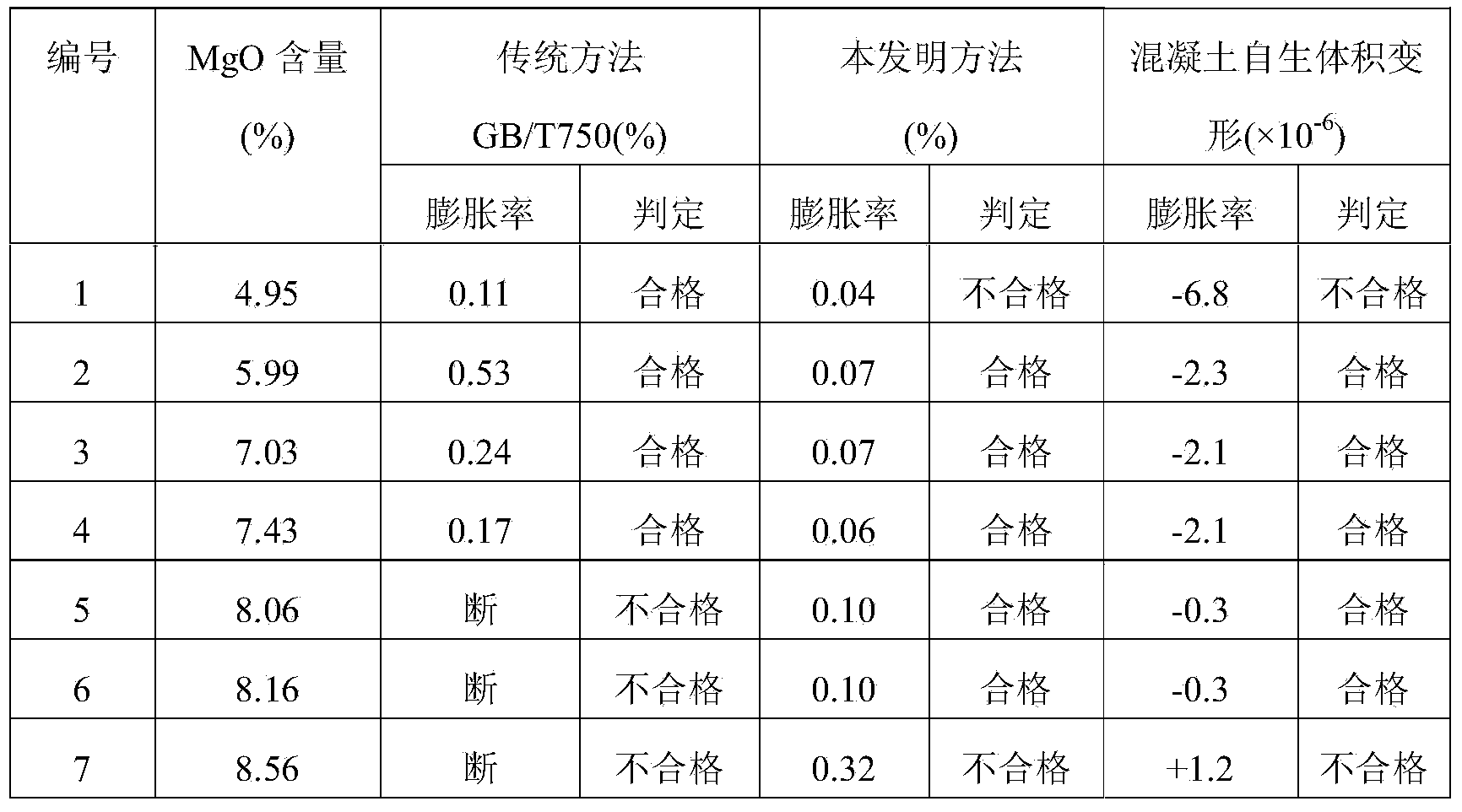

[0016] In the low-heat Portland cement (KH=0.86+0.02, n=0.80+0.02, p=0.80+0.02) produced by Sichuan Jiahua Cement Co., Ltd., adjust the ratio of raw materials so that MgO in clinker=4.95%, 5.99 %, 7.03%, 7.43%, 8.06%, 8.16%. According to the traditional GB / T750 test method, the method for evaluating the stability of high MgO cement used in hydraulic concrete according to the present invention, and the concrete autogenous volume deformation test, the results are shown in Table 1.

[0017] The present invention evaluates the method for the high MgO cement stability of hydraulic concrete, comprises the following steps:

[0018] Step 1, mix the high MgO cement to be tested, ISO standard sand, and water according to the weight ratio of 450:1350:225 to prepare mortar;

[0019] Step 2, use the mortar prepared in step 1 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com