Free-combination type multi-functional wire distributing plate

A breakout board and combined technology, applied in the manufacturing of electrical components, circuits, cables/conductors, etc., can solve the problems of increasing the workload of workers, complicated disassembly and replacement, troubled operators, etc., to achieve easy operation and reduce production costs. , the effect of convenient and quick operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] For ease of understanding, the specific structure and working method of the present invention are described as follows in conjunction with the drawings:

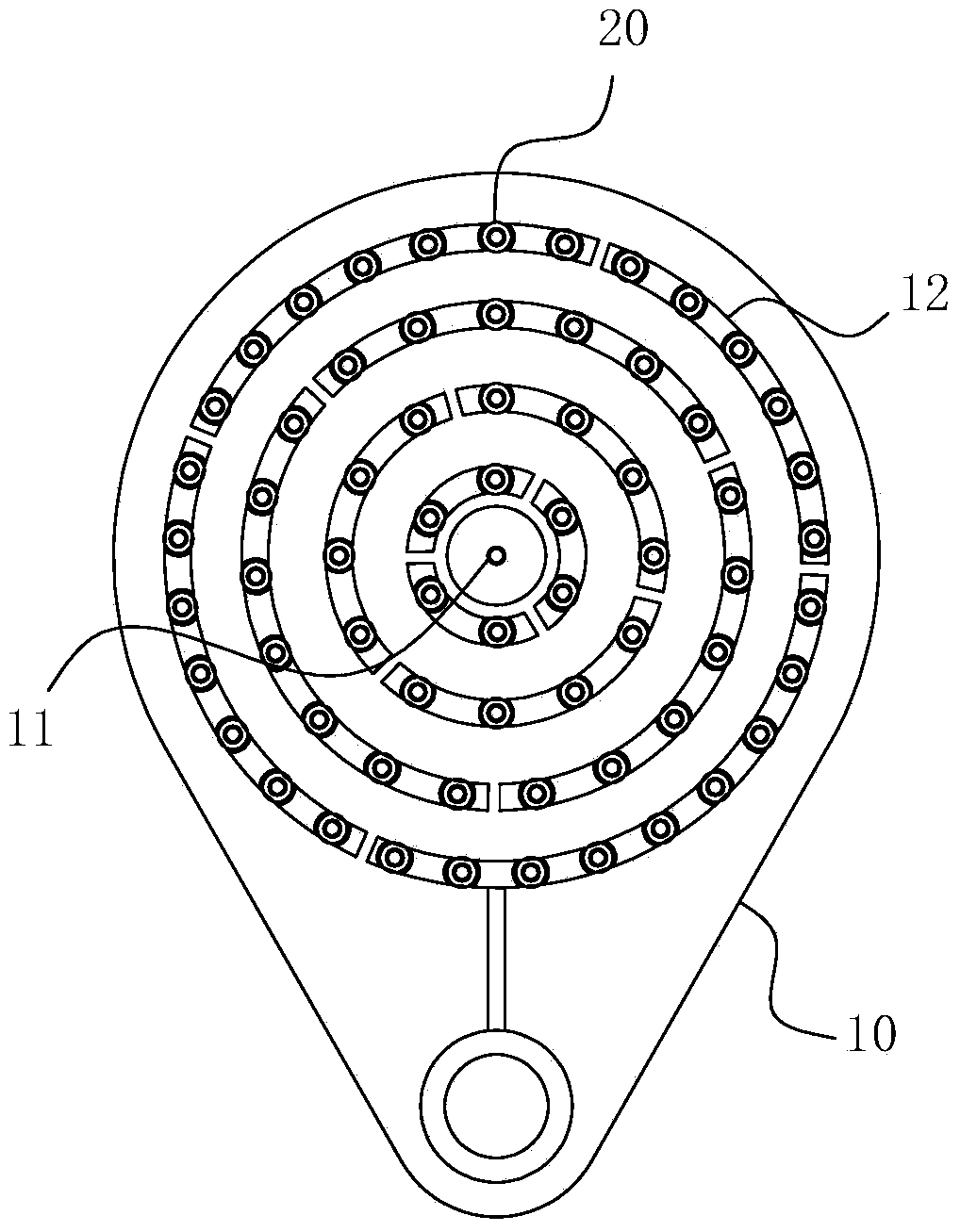

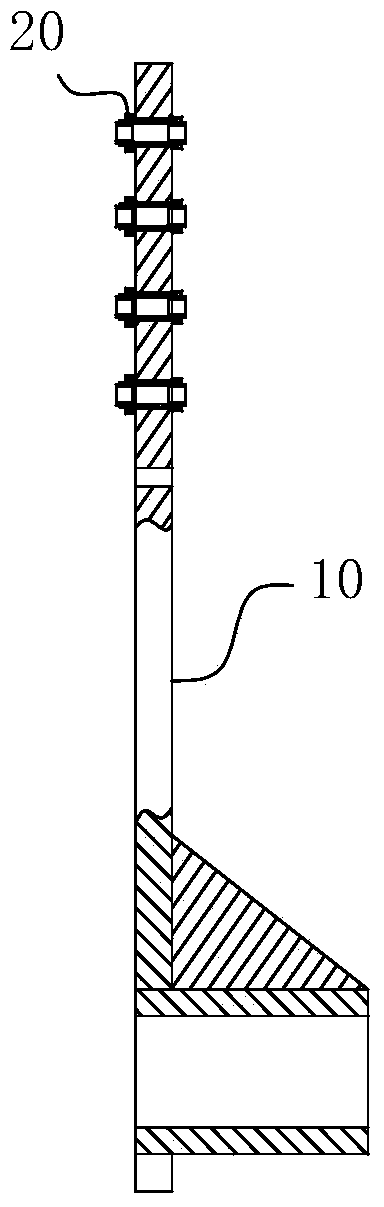

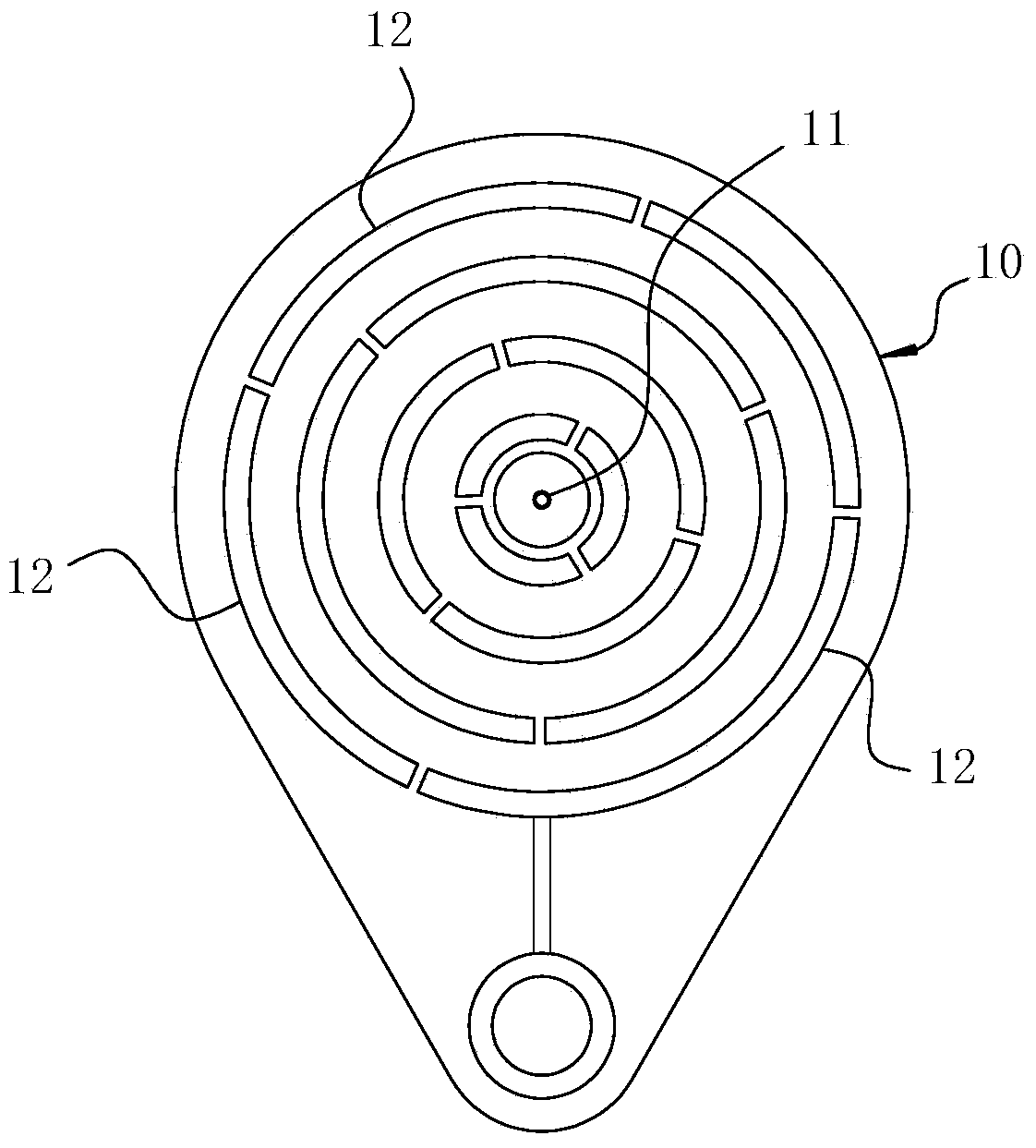

[0028] The actual structure of the present invention, such as Figure 1-4 As shown, it can be seen that in addition to the intermediate hole 11 that must exist in the distribution board, a plurality of arc-shaped waist-shaped holes (that is, the aforementioned arc-shaped holes 12) are also hollowed out on the disc-shaped distribution board base 10. ), and the waist-shaped holes are enclosed to form a ring-shaped layout; at the same time, the waist-shaped holes forming a ring-shaped layout are a group of hole layers, and the hole layers are multi-layer concentric circles arranged according to actual conditions. . A sleeve part 20 with a replaceable porcelain eye 23 is placed in the waist-shaped hole, and the sleeve part 20 is equidistantly and equally divided into the hollow arc-shaped waist-shaped hole and forms a fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com