Extensible type chip mounter

A technology of placement machine and placement head, which is applied in the direction of assembling printed circuits with electrical components, etc., can solve the problem that the coaxiality of the stepping motor and the suction pen is difficult to ensure, the adjustment of the chip angle is difficult to achieve, and the lateral size of the placement head is large. problems, to achieve the effect of increasing the maximum placement speed, subtracting the auxiliary placement mechanism, and solving processing problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Specific embodiments of the present invention are given below. It should be noted that the present invention is not limited to the following specific embodiments, and all equivalent transformations made on the basis of the technical solutions of the present application fall within the protection scope of the present invention.

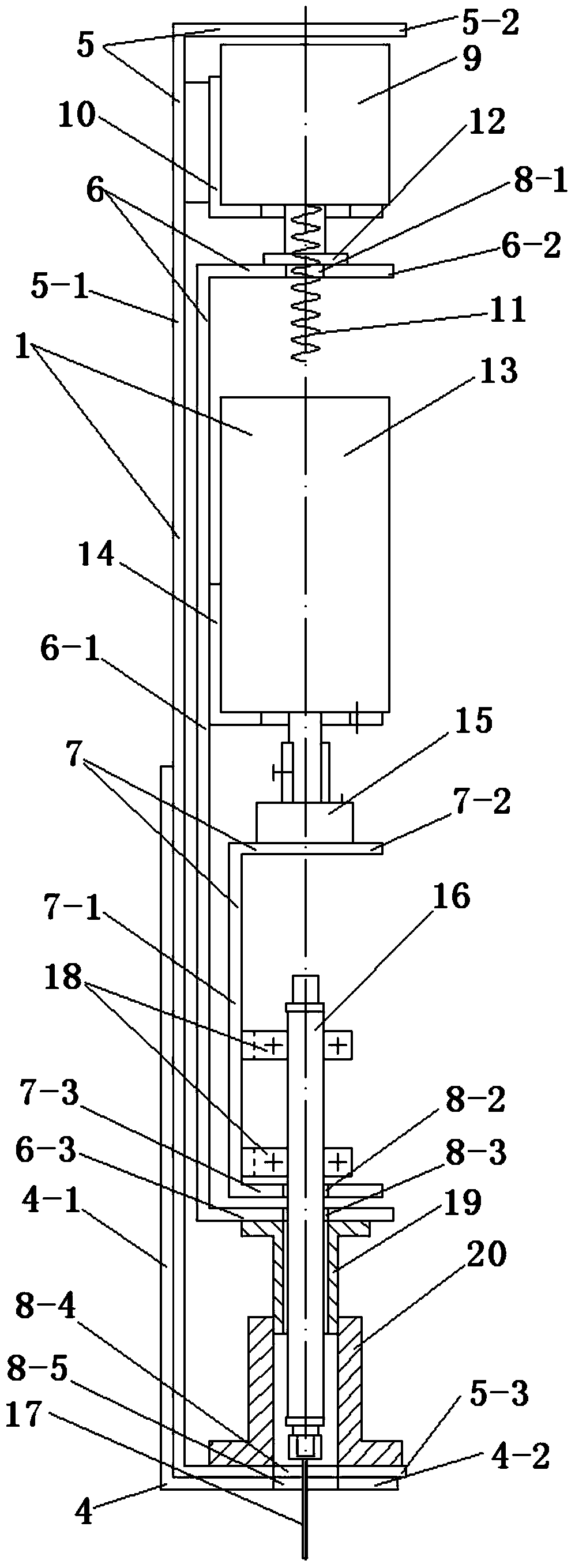

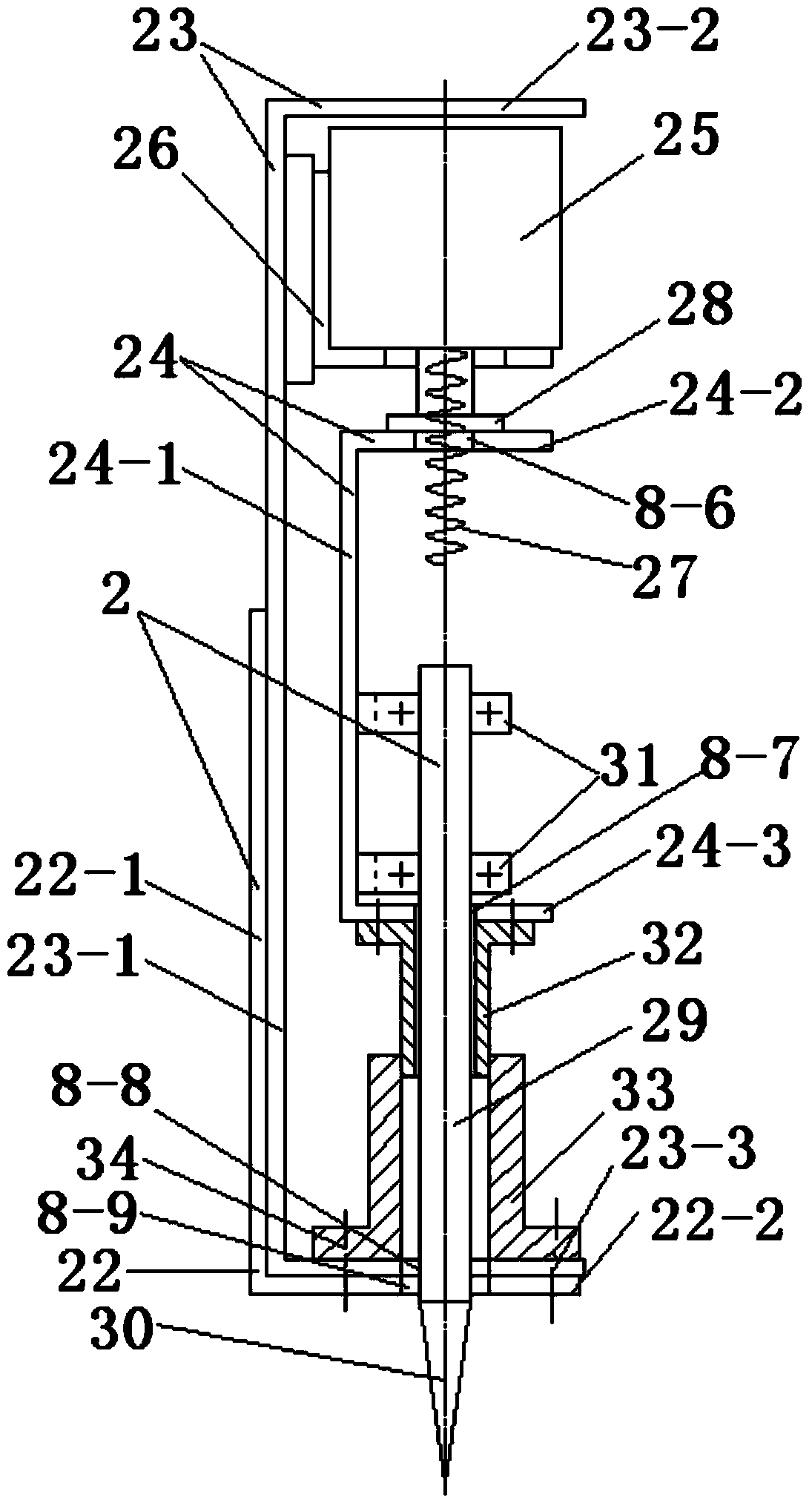

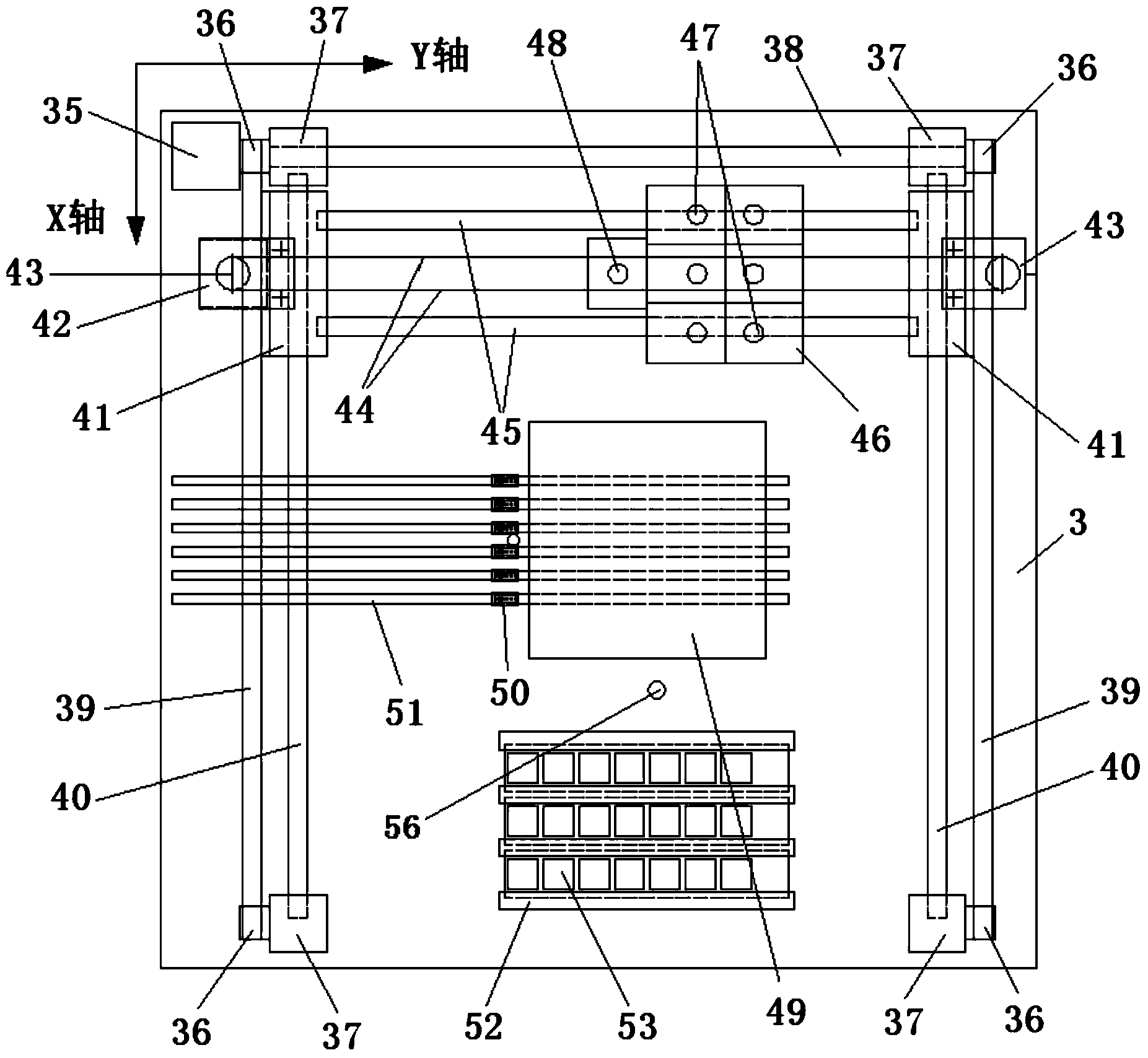

[0049] Follow the above technical solutions, such as Figure 1 to Figure 9 As shown, this embodiment provides an expandable placement machine, which includes a placement head 1. The placement head includes a connecting seat 4, a supporting seat 5, and a lifting guide seat 6, and the connecting seat 4 It includes an "L"-shaped frame composed of a connecting seat back plate 4-1 and a connecting seat bottom plate 4-2 at the bottom end. The supporting seat 5 includes a supporting seat back plate 5-1 and a supporting seat top plate 5-2 at both ends and A "U"-shaped frame composed of the support base plate 5-3, the lifting guide base 6 includes the lifti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com