Pneumatic tire and method for producing pneumatic tire

A technology for pneumatic tires and tire width direction, applied in tire parts, tires, tire edges, etc., can solve the problems of increasing the bead core pressure and the durability deterioration of the carcass ply, reducing stress concentration and preventing durability. The effect of sexual deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0076] Pneumatic tires according to the present invention were trial-manufactured to evaluate performance in the following manner.

[0077] Example tires were manufactured in sizes 11.00R20 and 12.00R20 and conventional tires were manufactured in sizes 11.00R20 and 12.00R20

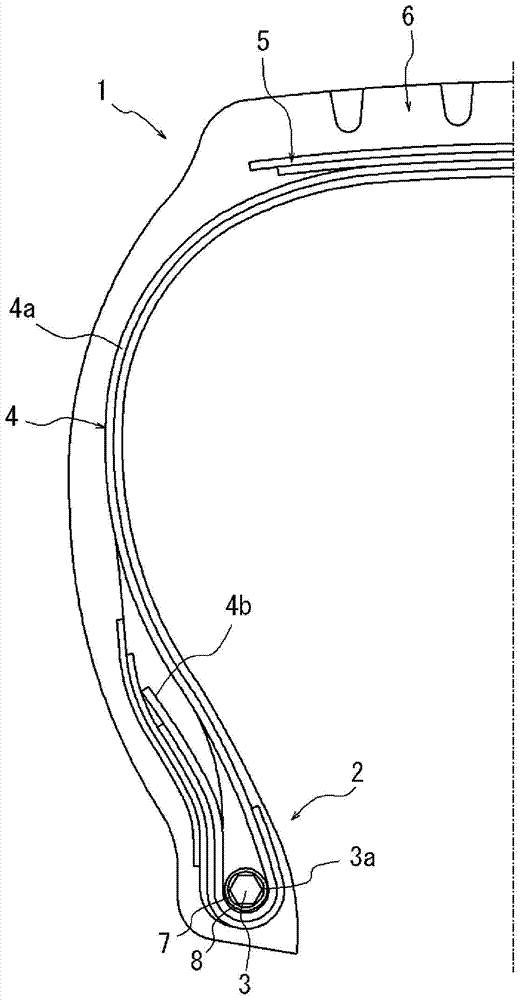

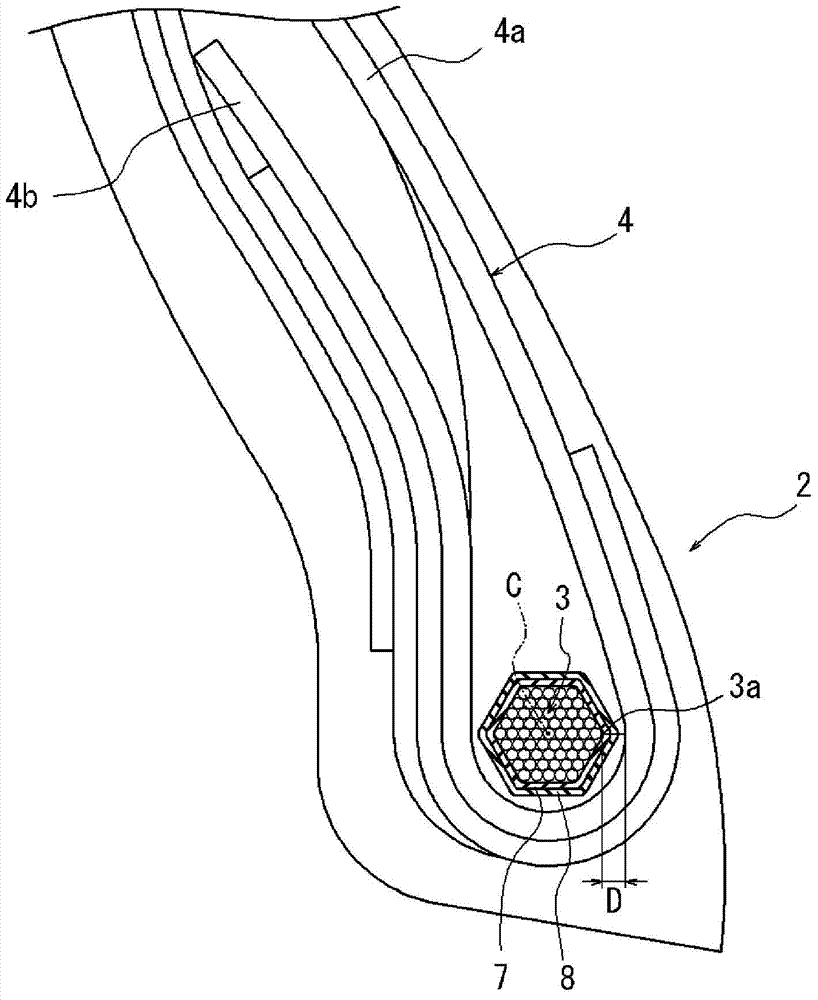

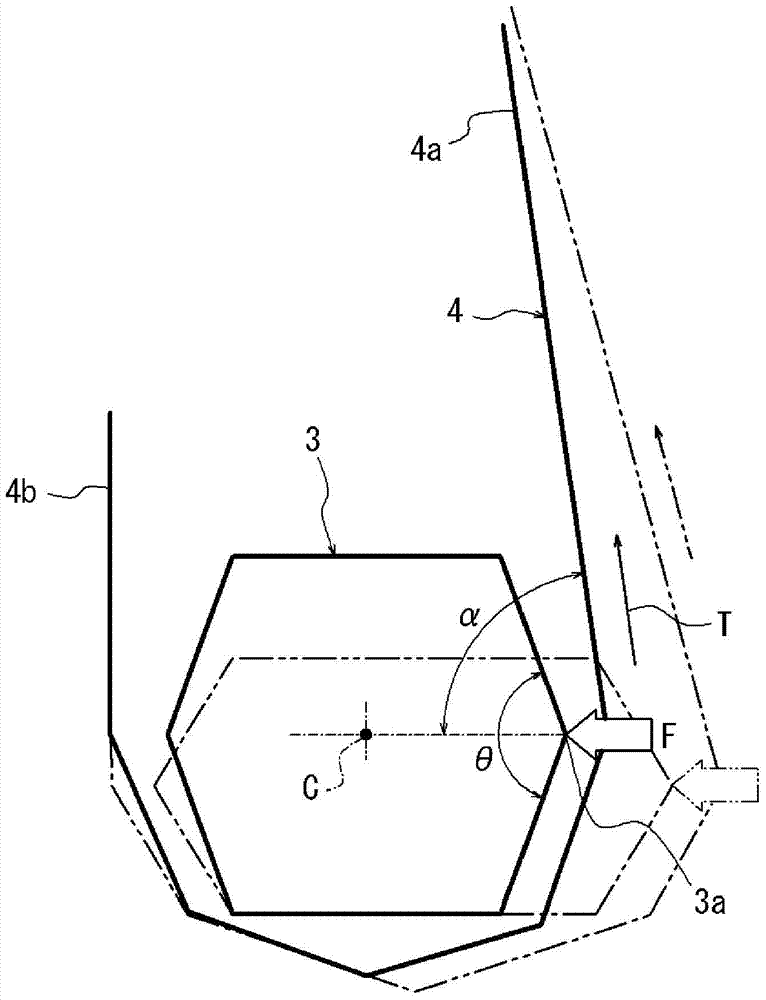

[0078] Example tire 1 with size 12.00R20 has the same figure 1 with figure 2 The same features as the tire 1 shown in . Two layers of organic fiber reinforcement are formed around the bead core of the tire. The organic fiber cords of the organic fiber reinforcement layer are made of nylon. The angle of intersection between the cords in the inner reinforcement layer and the cords in the outer reinforcement layer was 100 degrees.

[0079] Such as Image 6 As shown in (a), the bead core of Example tire 1 was formed by repeatedly winding a cord to form nine segments. The number of rows in each segment from the innermost section to the outermost section in the tire radial direction increases and decrea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com