Marinating unit

A kind of unit and braised technology, applied in food preparation, non-electric variable control, control/regulation system, etc., can solve the problems of not having a set of braised machine supporting system, wasting the price of braised soup, and not being able to collect braised soup, so as to ensure Quality and Safety, Time and Cost Savings, Effect of Reduced Exposure Time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

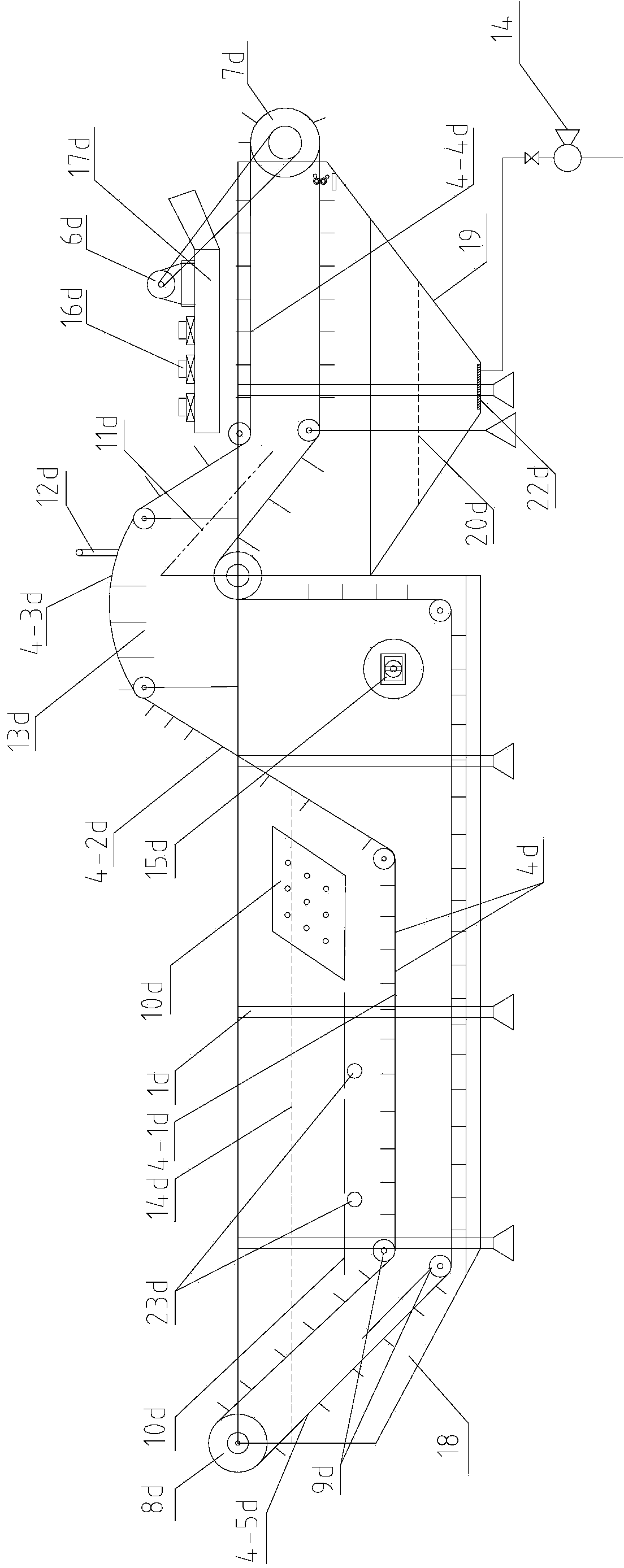

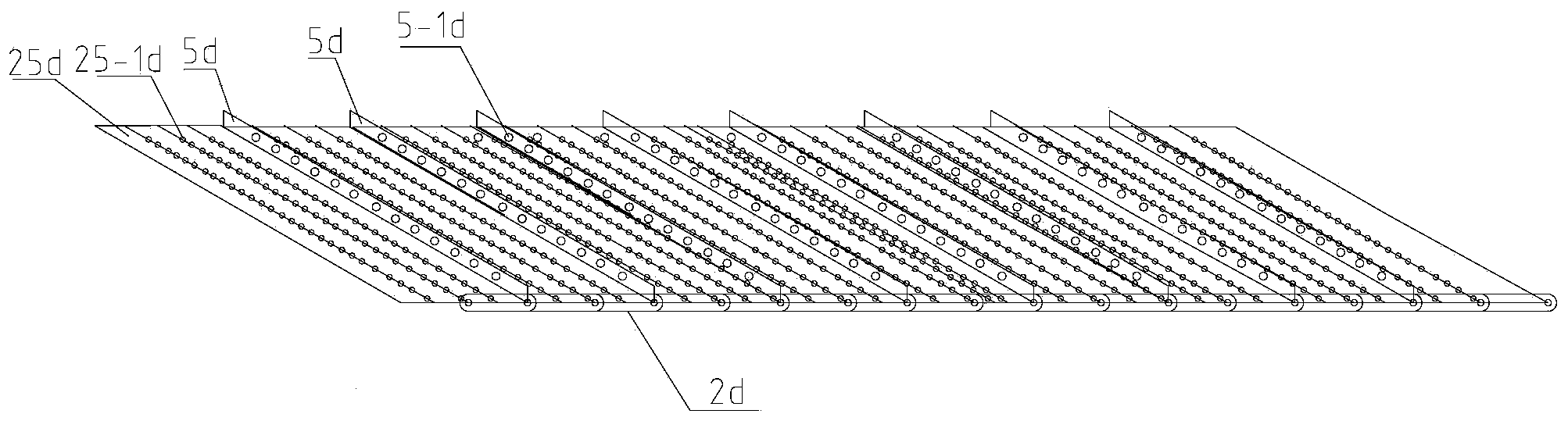

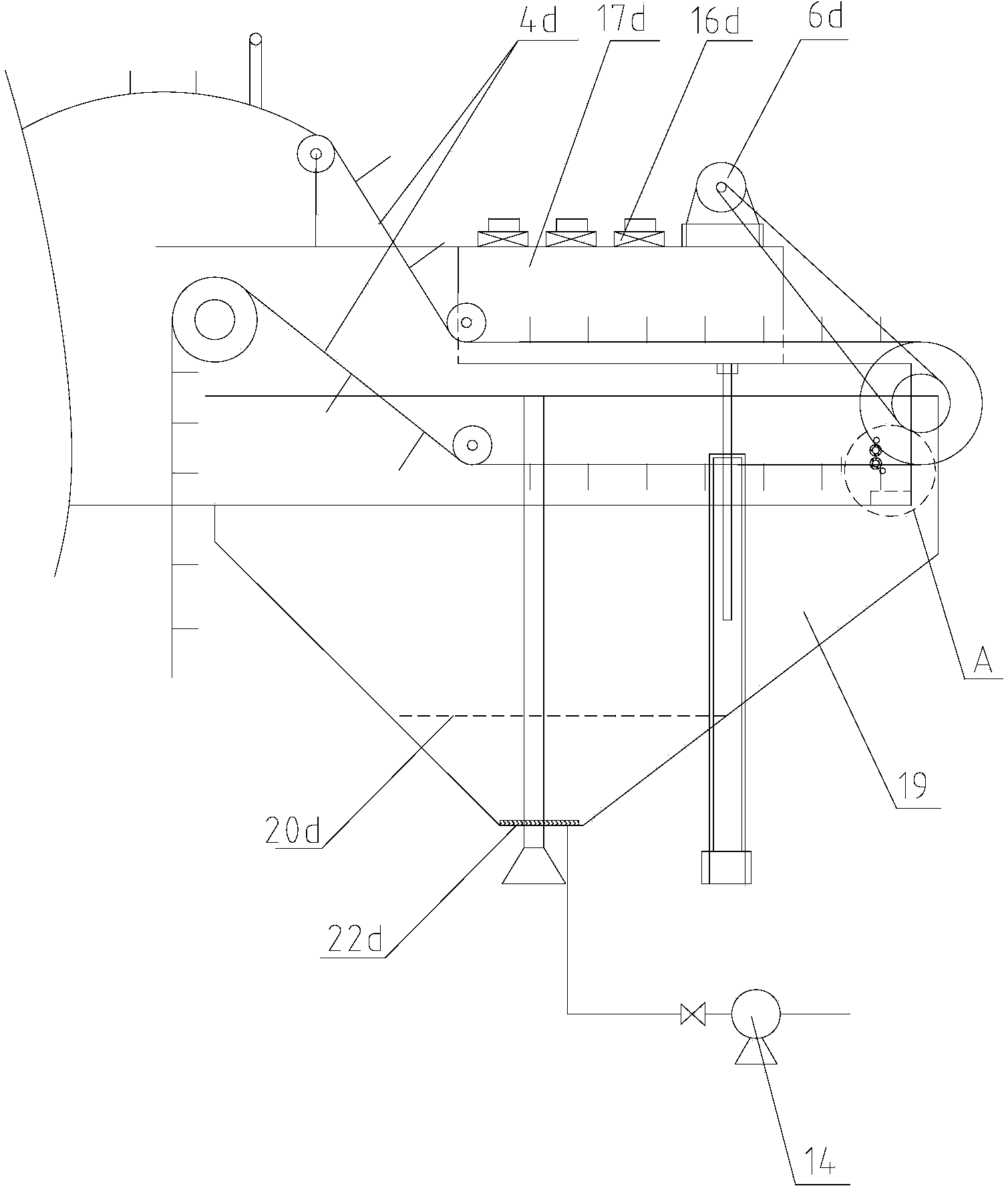

[0053] see figure 1 with Figure 4 , the stewed machine of the present invention comprises the stewed box 18 that is installed on the frame 1d and the delivery mechanism 4d that is arranged in the stewed box 18, and one end of the said stewed box 18 is also connected with the stewed soup collection tank 19, and the described stewed box 18 Attached to rack 1d. The conveying mechanism 4d includes a brine section 4-1d located in the brine box 18, a lifting section 4-2d connected to the brine section 4-1d and protruding upwards outside the brine box 18, and a spraying section connected to the lifting section 4-2d. Section 4-3d and the air-cooled section 4-4d connected with the spray section 4-3d, wherein, the spray section 4-3d is provided with a spray device, and the air-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com