Oxygen making machine used molecular sieve adsorption column

A molecular sieve and adsorption tower technology, applied in the field of molecular sieve adsorption towers for oxygen generators, can solve the problems of affecting the service life of molecular sieves, difficult to take out molecular sieves, and increased mobility of molecular sieves. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

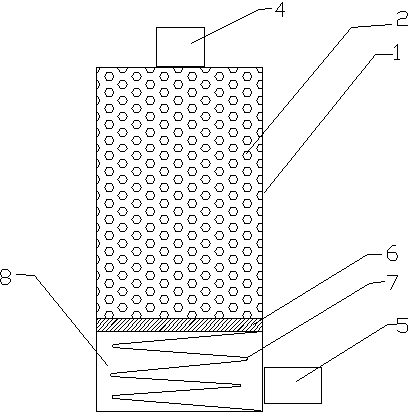

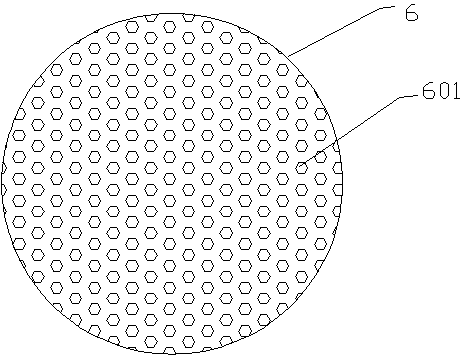

[0017] Such as figure 1 As shown, a molecular sieve adsorption tower for an oxygen generator includes a cylinder body 1 and a molecular sieve 2. The cylinder body includes an air inlet end and an air outlet end. The body 1 is provided with an air flow equalizer 6, and the molecular sieve 2 is arranged in the cavity formed by the air flow equalizer 6 and the end face of the gas outlet end. The reserved space 8 between the molecular sieve 2 makes the high-pressure air flow output by the compressor not directly impact the molecular sieve particles near the port, reducing the pulverization of the molecular sieve, and the air flow equalizer 6 does not contact the cavity wall of the cylinder 1.

[0018] A compression spring 7 is arranged in the reserved space 8, and the two ends of the compression spring 7 are respectively fixedly connected with the air flow equalizer 6 and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com