Dual-mode quick granulating machine

A granulator and fast technology, applied in the direction of extrusion and granulation of raw materials, can solve the problems of high equipment manufacturing cost, high power consumption, complex structure, etc., and achieve the effects of improving stability, improving functional efficiency and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing, the present invention will be further described:

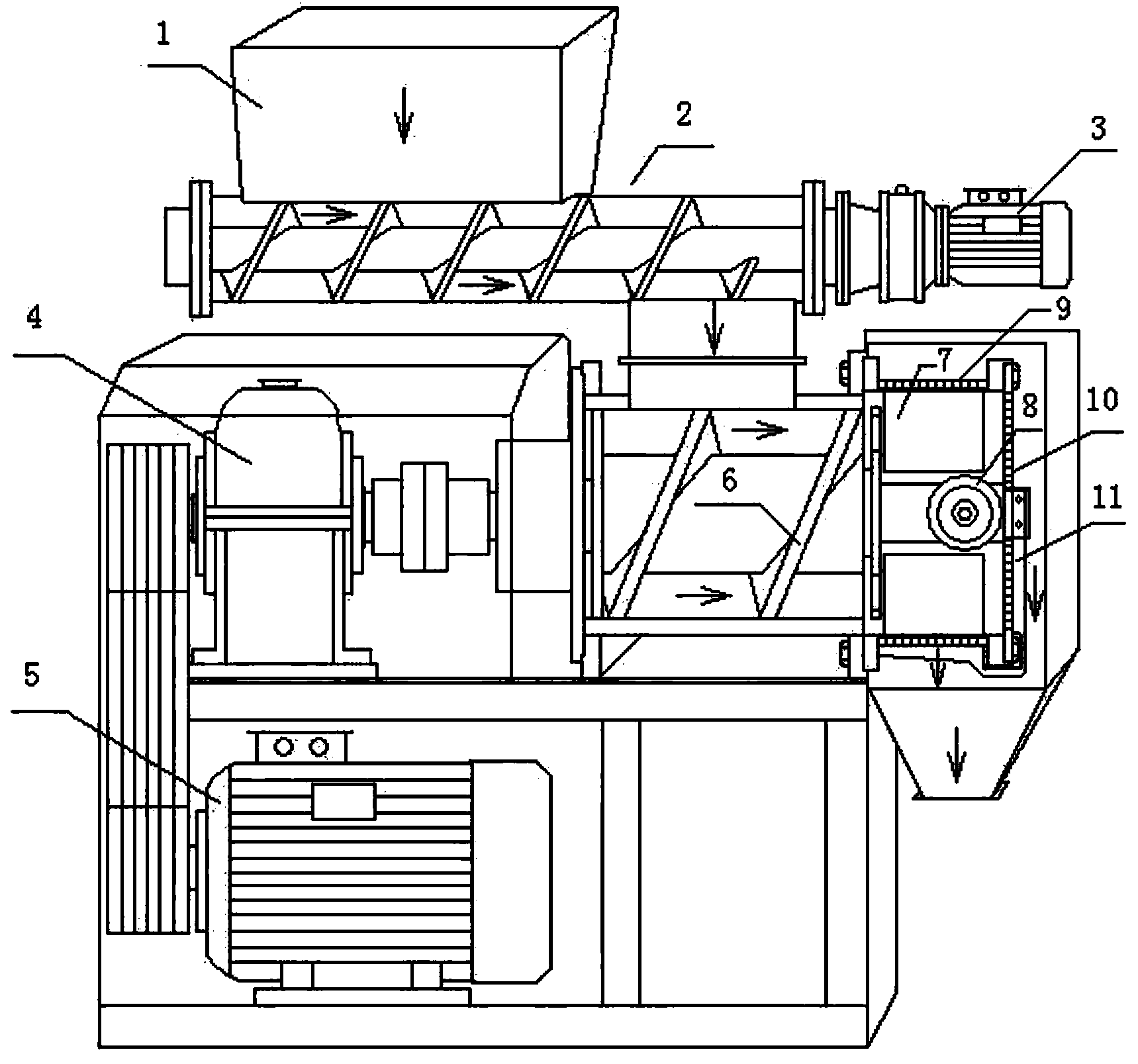

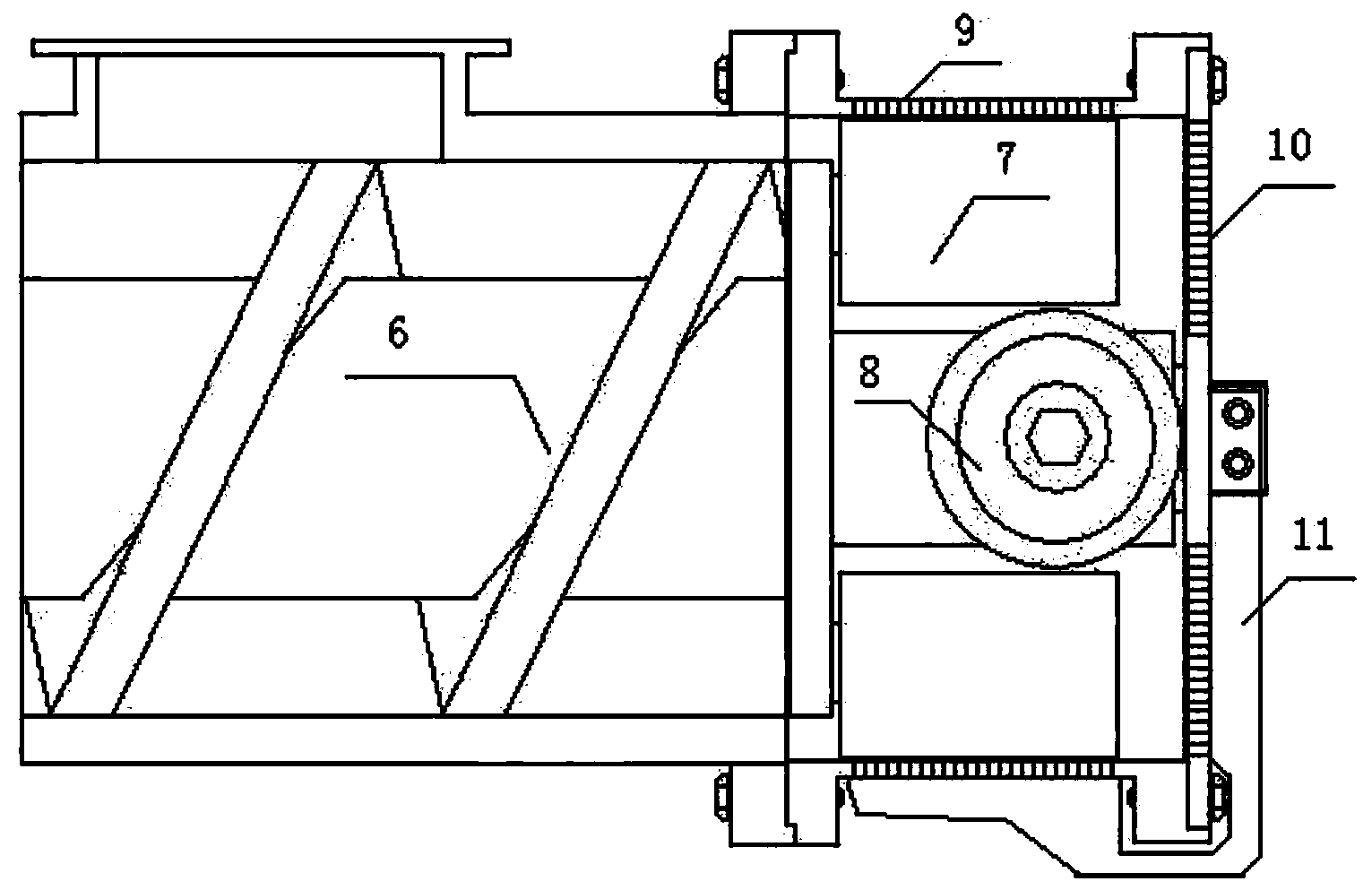

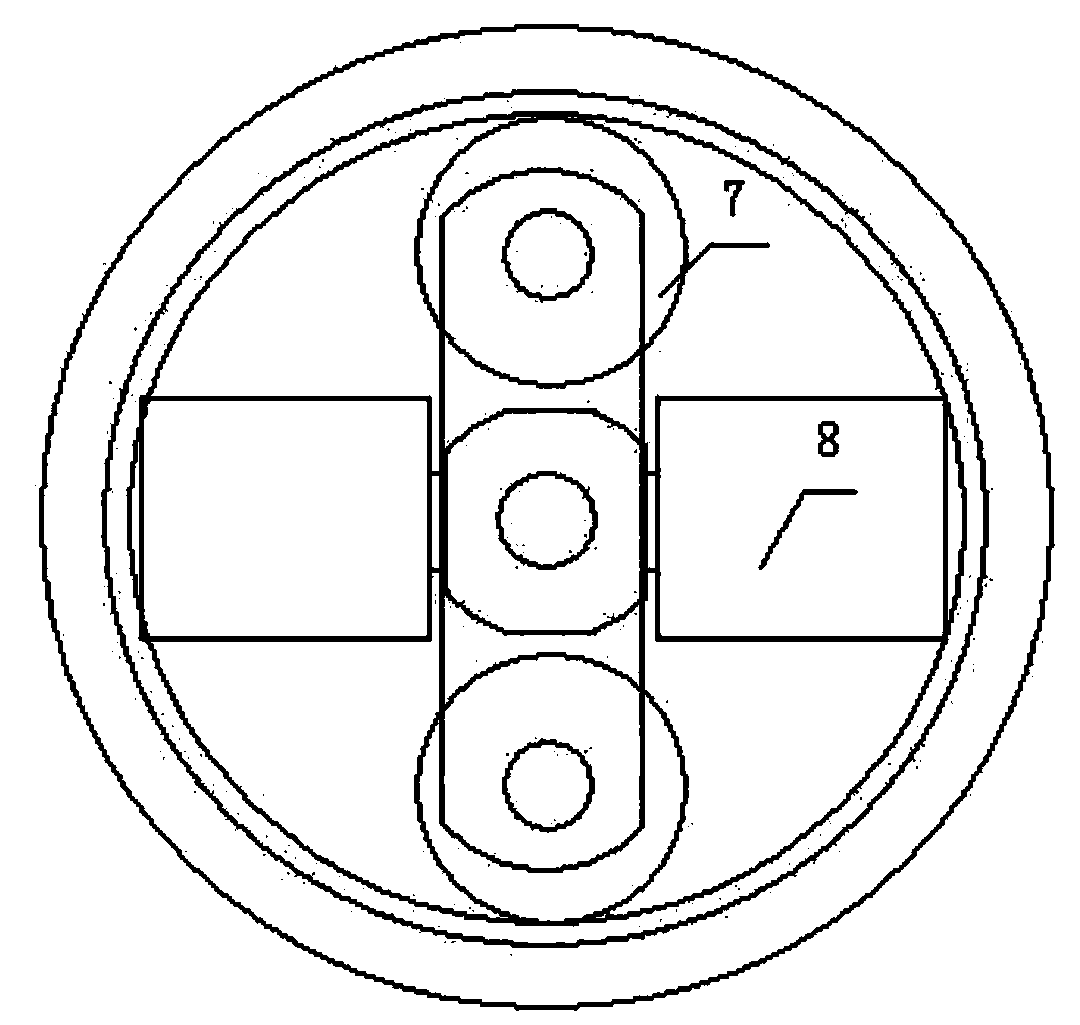

[0020] The double-mode rapid granulator of the present invention includes a feeder, a granulator and a control system, the feeder is installed above the granulator, and the feeder is controlled by a feed hopper 1 and a PID to control the quantitative feeding screw auger 2 and frequency conversion motor 3, the top of one end of the PID controlled quantitative feeding auger 2 is connected to the feed hopper 1, the bottom of the other end of the PID controlled quantitative feeding auger 2 is provided with a discharge port, and the PID controls the quantitative feeding screw The hinge dragon 2 is driven by a frequency conversion motor 3; the granulator consists of a granulation main motor 5, a reducer 4, a forced pressure conveying screw hinge dragon 6, a radial pressure roller 7, an axial pressure roller 8 and a ring mold 9, a plane The mold 10 and the L-shaped rotary cutter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com