A variable-speed automatic tool-feeding device for a bench drill

A technology of automatic tool feeding and bench drilling, applied in the field of machinery, can solve the problems of unreasonable design of the tool feeding mechanism, inconvenient adjustment of feed amount, high cost of quality requirements, etc., to facilitate automatic tool feeding and processing of various materials, and convenient adjustment Fast, the effect of improving labor production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

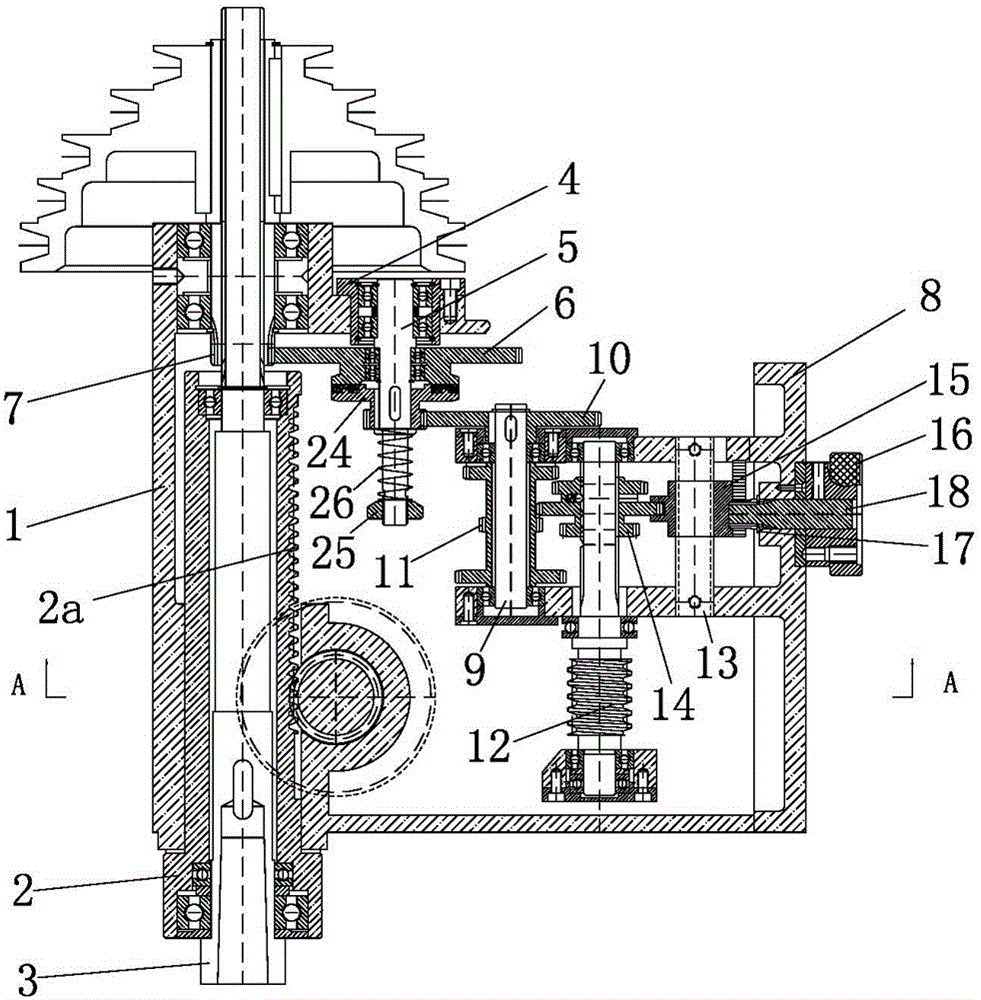

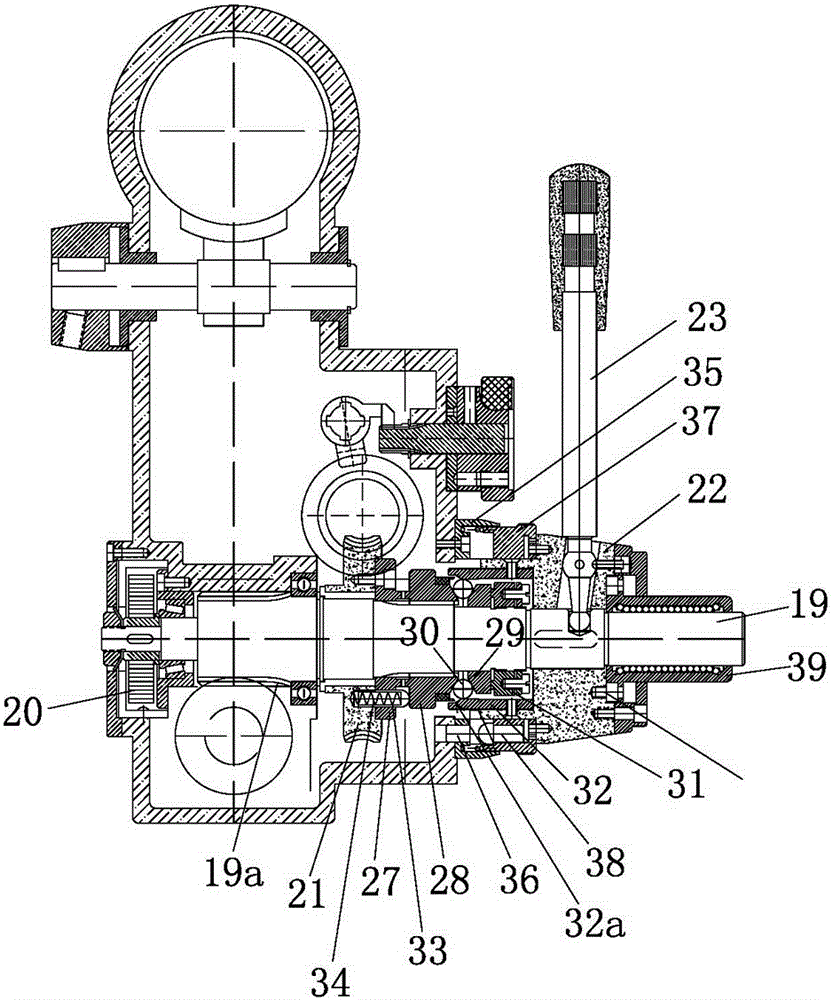

[0015] Such as figure 1 , figure 2 As shown, the variable-speed automatic tool feed device of this bench drill includes a headstock 1, a sleeve 2 and a spindle 3. The sleeve 2 is installed in the headstock 1 and the spindle 3 is installed in the sleeve 2. The headstock 1 is fixed There is a bearing seat 4, and the bearing seat 4 carries a gear fixed shaft 5, a feed fixed gear 6 is fixed on the gear fixed shaft 5, a fixed gear 7 meshing with the feed fixed gear 6 is fixed on the main shaft 3, and the headstock 1 A gear rack 8 is fixedly connected to the gear rack 8. A feed fixed shaft 9 is installed on the gear rack 8. A feed gear 10 and a fixed three-teeth gear 11 are fixed on the feed fixed shaft 9. The feed gear 10 dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com