Spherical rolling and pressing cutter

A rolling knife and ball-shaped technology, applied in the field of machining tools, can solve problems such as uneven force application, affecting the precision and quality of machining, and achieve the effect of avoiding uneven force and improving precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

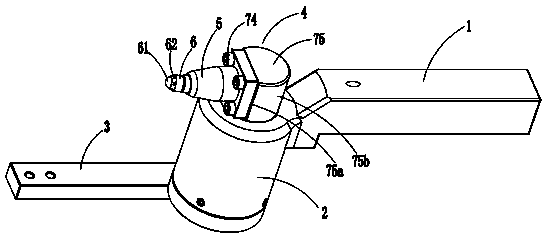

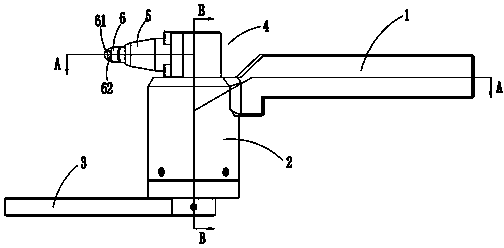

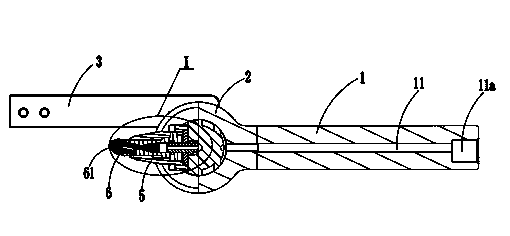

[0032] Such as Figure 1 to Figure 9 Shown is the structural representation of the present invention,

[0033] The reference signs are: tool handle 1, oil inlet passage 11, oil inlet 11a, connector 2, connection passage 21, central body 22, sealing sleeve 23, upper cover 24, guide ring groove 24a, bearing 25, star Type sealing ring 26, oil circuit protection sleeve 27, guide ring 28, guide rod 3, cutter head 4, rolling head 5, oil outlet passage 51, rolling ball retainer 6, external thread 6a, spherical cavity 6b, rolling Ball 61, oil flushing port 62, connecting seat 7, through hole 7a, screw hole 7b, nozzle 71, cone surface 71a, stepped hole 71b, transition sleeve 72, gasket 73, screw 74, rotating head 75, plane 75a, cylinder Surface 75b, shrapnel support ring 81, shrapnel 82, guide sleeve 83, connecting ring 84, and workpiece 9.

[0034]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com