An assembly method of double gears for seamless steel pipe cold rolling mill rolls

A technology of double gears and seamless steel tubes, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as high requirements for operator skills and experience, low assembly accuracy of double gears, and rising gear processing costs. Achieve the effect of low operating skill requirements, easy implementation, and reduced operating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

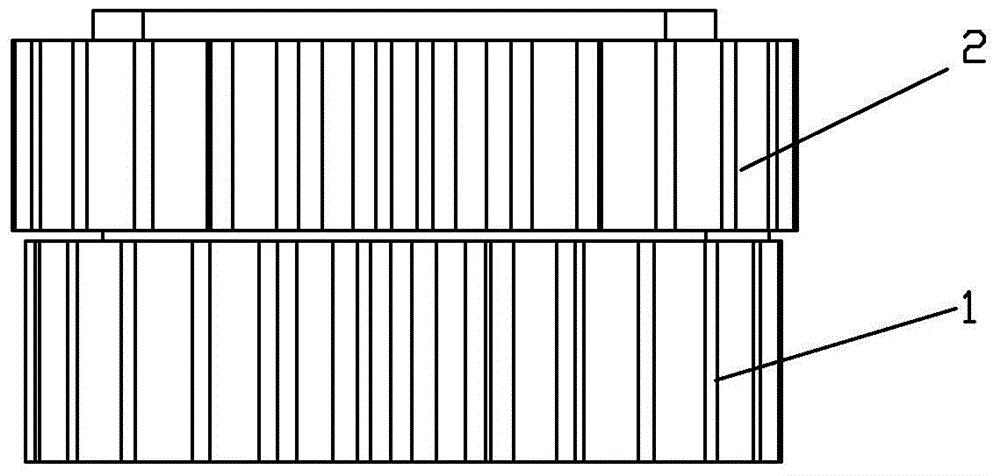

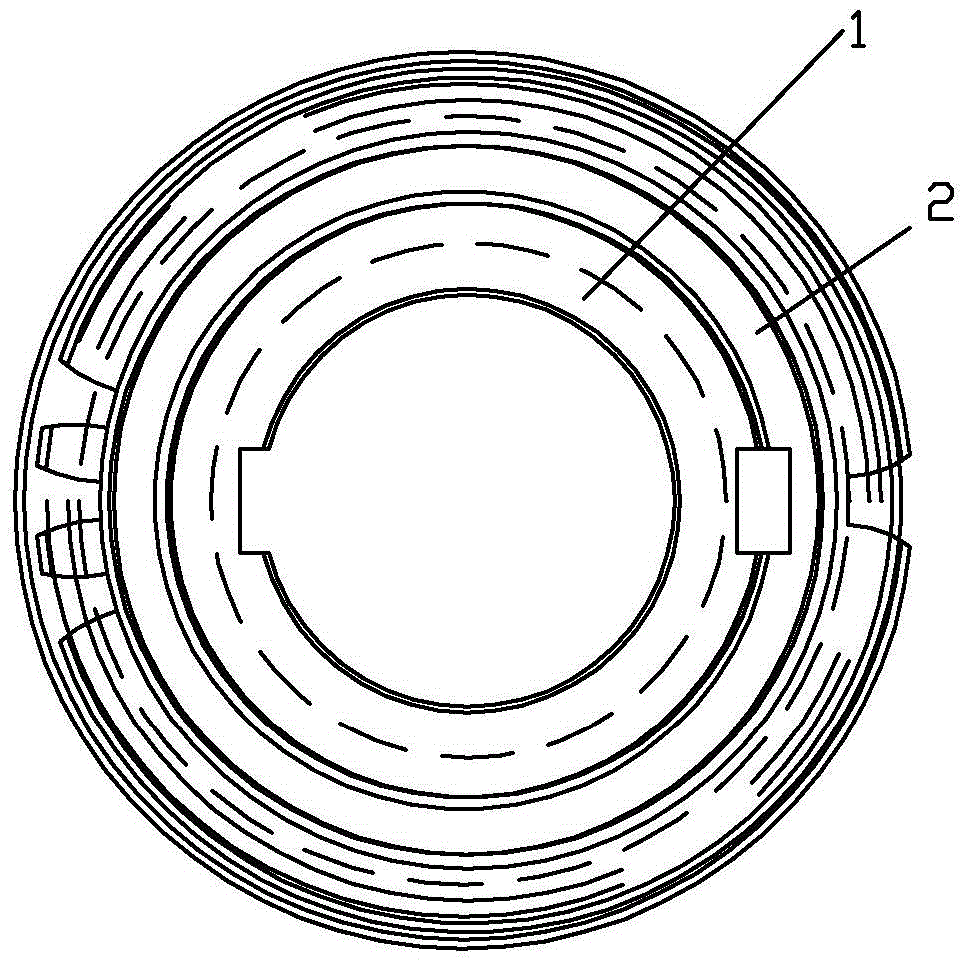

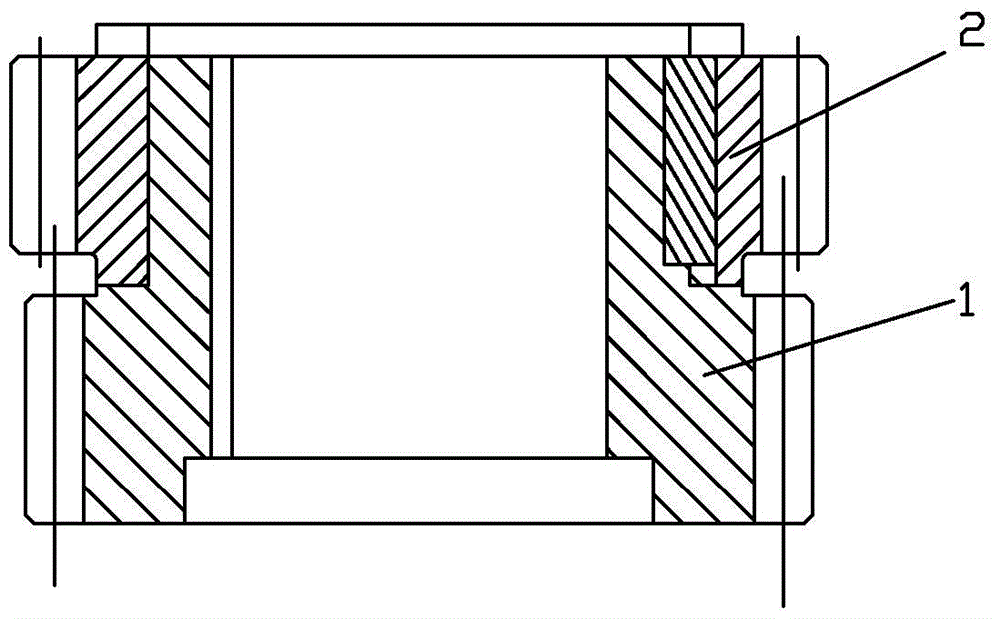

[0090] Taking the double gear (m=15, Z1=25, Z2=26) of the active roll (lower roll device) of ХПТ-55 cold rolling pipe mill as an example, the assembly process is as follows:

[0091] 1. Gear preparation:

[0092]1) Receiving gears: According to the requirements of the work order, the gear parts composed of double gears are obtained from the warehouse;

[0093] 2) Cleaning of gears: cleaning and wiping gear inner holes and tooth shapes, file deburring, keyway grinding, pre-assembly, etc.;

[0094] 3) Inspection: Measure the inner hole of the gear (diameter 260, 180mm), the journal of the long handle gear (260mm), the keyway width (45mm), the tooth profile angle (top width 21.63mm) and other data;

[0095] 2. Assembly preparation:

[0096] 1) Tool preparation: place the standard flat plate on the inspection work platform, wipe it clean, place the calibration measuring stick, feeler gauge, hand hammer, top counterweight, etc. on the work platform, and wipe the surface clean;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com