Multi-cabin full-automatic conveying rail

A transmission track, fully automatic technology, applied in conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problems of low efficiency, high level of operation, low level of automation, etc., to reduce operating requirements, reduce labor intensity, reduce The effect of human cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

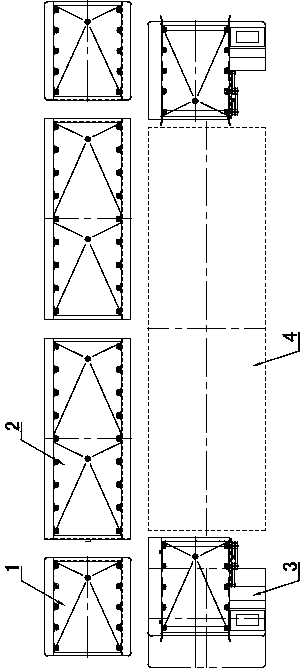

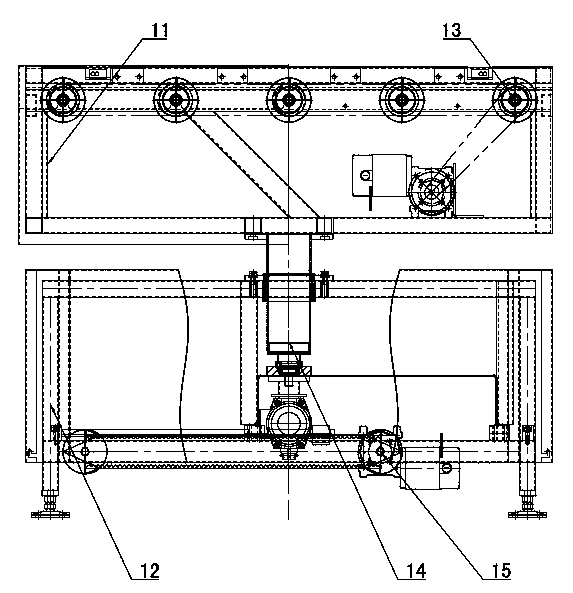

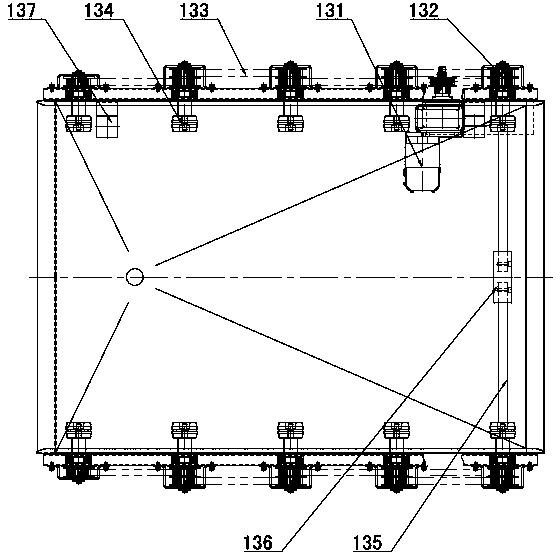

[0022] Figure 1~5 It is the best embodiment of the present invention, below in conjunction with attached Figure 1~5 The present invention will be further described.

[0023] Refer to attached figure 1 , 2 : Multi-chamber fully automatic transmission track, including multi-chamber washer-disinfector 4, the two sides of the inlet and outlet of multi-chamber washer-disinfector 4 are respectively equipped with automatic translation and rotation platform 3, and one side of automatic translation and rotation platform 3 is provided with automatic rotation platform 1, The same side of the multi-chamber washer-disinfector 4 is provided with an automatic transmission track 2 composed of a plurality of automatic rotating platforms 1 . The automatic rotating platform 1 is composed of an upper frame 11, a lower frame 12, a roller conveying system 13 and a platform rotating system 14. The lower frame 12 is supported on the horizontal ground by supporting legs, and the platform rotating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com