Culture apparatus and method for complete autotrophic nitrogen removal granule sludge

A fully autotrophic denitrification and granular sludge technology, which is applied in the field of sewage biological treatment, can solve the problems of low denitrification efficiency, poor sludge settling performance and poor operation stability of the anaerobic ammonium oxidation denitrification method, and achieve the goal of reducing pollution. Mud output, improved stability, good impact resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

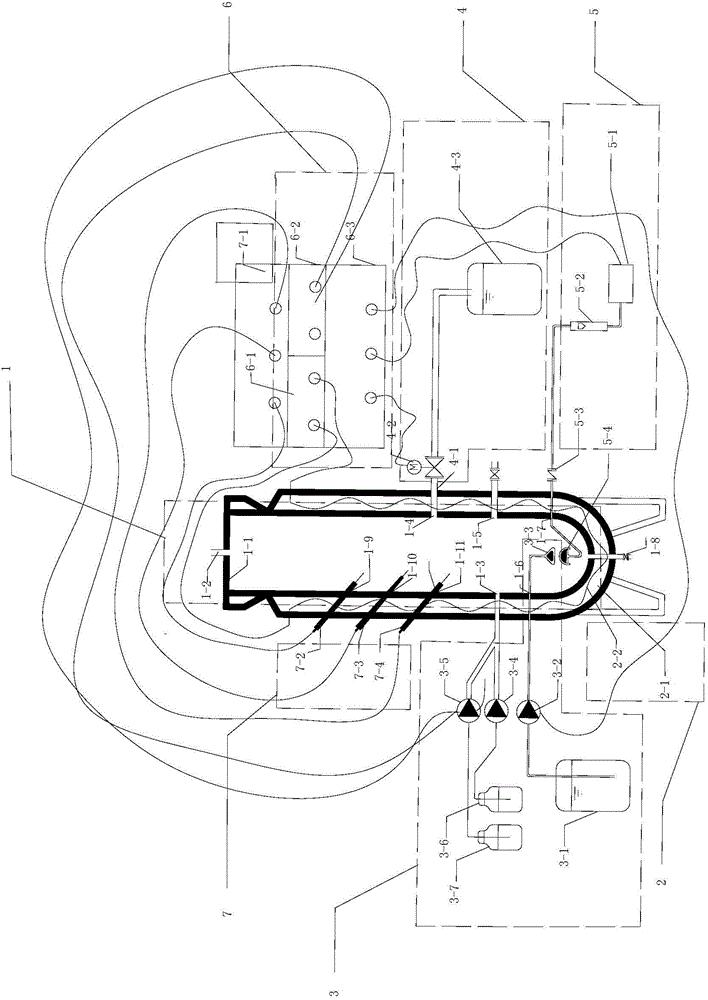

[0049] Specific implementation mode one: refer to figure 1 Specifically explain this embodiment, a kind of fully autotrophic denitrification granular sludge cultivation device described in this embodiment, the device includes a U-shaped reactor body 1, a heat preservation system 2, a water inlet system 3, a drainage system 4, an exposure Gas system 5, automatic control system 6 and parameter monitoring system 7;

[0050] The thermal insulation system 2 includes a thermal insulation layer 2-1 and a resistance wire 2-2;

[0051] Water inlet system 3 comprises the water inlet tank 3-1 that water is housed, the water inlet metering pump 3-2, the water inlet filter head 3-3, the acid inlet metering pump 3-4, the alkali inlet metering pump 3-5, is equipped with Acid storage bottle 3-6 and alkali storage bottle 3-7 are housed;

[0052] The drainage system 4 includes a drainage pipe 4-1, a solenoid valve 4-2 and a water outlet tank 4-3;

[0053] The aeration system 5 includes an ai...

specific Embodiment approach 2

[0066] Specific embodiment 2: This embodiment is a further description of a kind of fully autotrophic denitrification aerobic granular sludge cultivation device described in specific embodiment 1. In this embodiment,

[0067] The aspect ratio of the U-shaped reactor body 1 is 14:1.

[0068] Under the same aeration rate, the larger the height-to-diameter ratio, the faster the apparent rising speed of the gas, and the greater the shearing effect of the generated water flow, which is conducive to the formation of granular sludge.

specific Embodiment approach 3

[0069] Specific embodiment three: This embodiment is a further description of a kind of fully autotrophic denitrification aerobic granular sludge cultivation device described in specific embodiment one. In this embodiment,

[0070] The diaphragm aeration head adopts a disc type diaphragm microporous aeration head.

[0071] The air bubbles produced by the disc-type diaphragm microporous aeration head are fine and uniform, with strong lifting capacity and high oxygenation efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com