PBL stiffening rectangular steel tube concrete space truss

A rectangular steel tube and space truss technology, which is applied in the direction of load-bearing elongated structural components, structural elements, building components, etc., can solve the problems of difficult connection between upper chord and concrete panel, low processing cost, difficult connection of supports, etc. To achieve the effect of easy guarantee of processing quality, simple processing and production, and large lateral rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

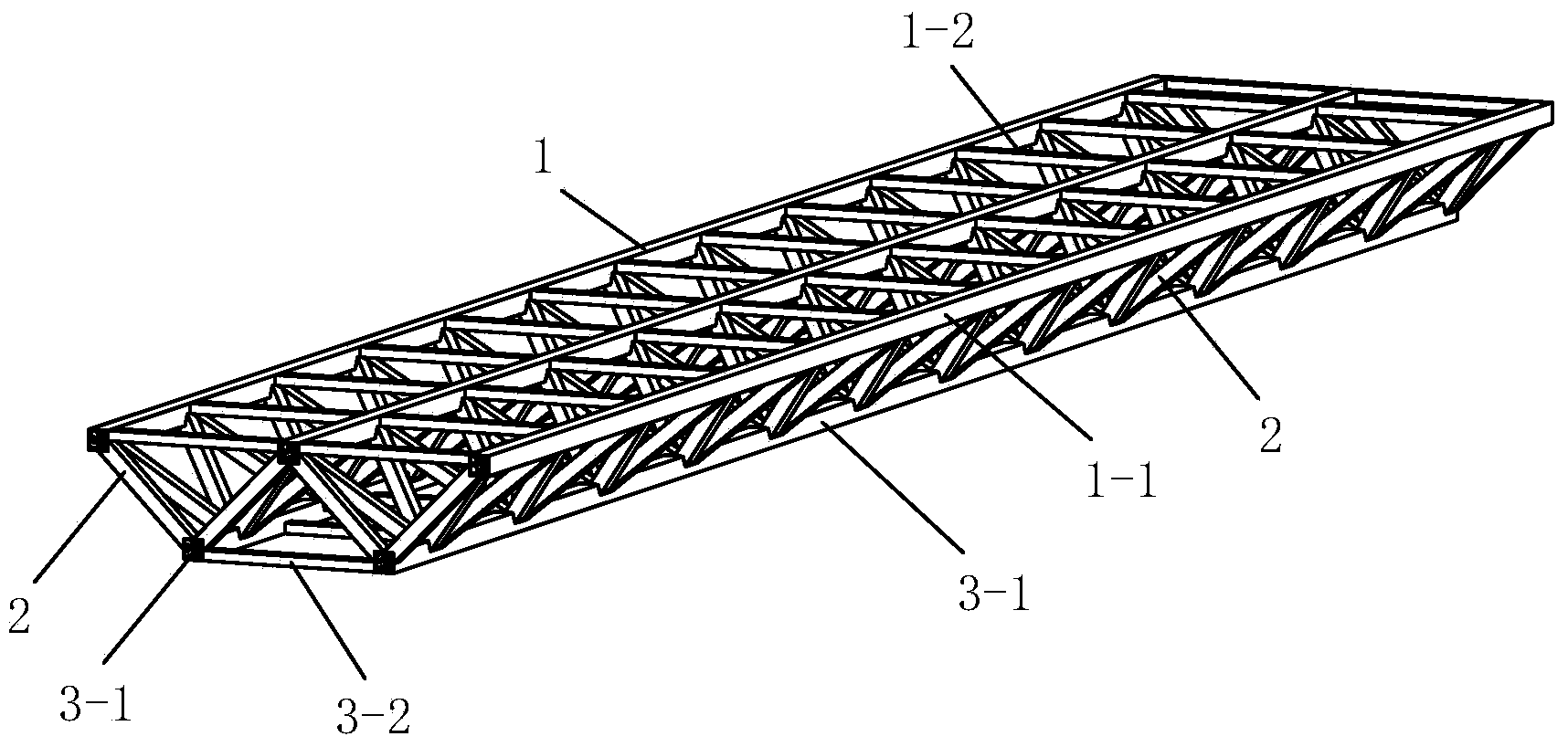

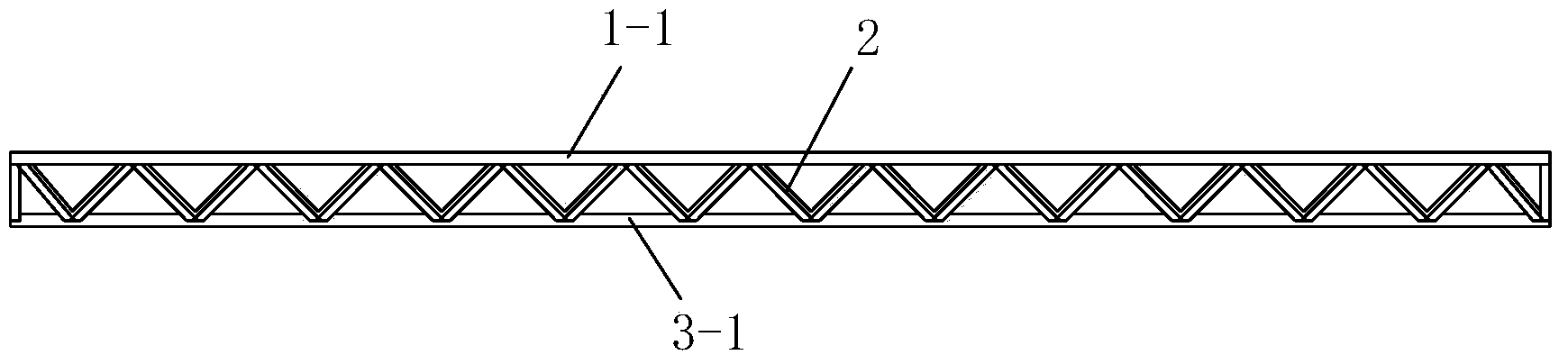

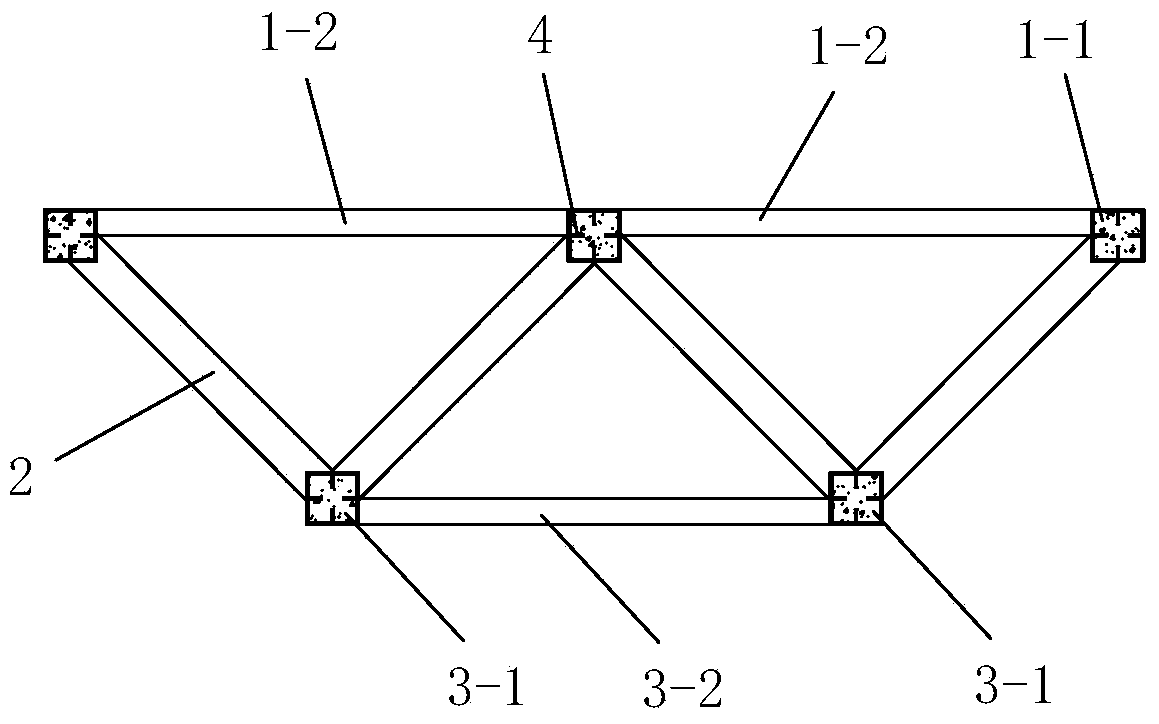

[0036] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 8As shown, the present invention includes an upper parallel link 1 and a lower parallel link 3 located directly below the upper parallel link 1, the upper parallel link 1 and the lower parallel link 3 are arranged in parallel, and the upper parallel link 1 is located directly above the lower parallel link 3 . The upper parallel link 1 includes multiple upper chords 1-1 arranged in parallel, and two adjacent upper chords 1-1 are fastened and connected by multiple upper connecting rods 1-2, and the multi-channel upper chords The rods 1-1 and the plurality of upper connecting rods 1-2 connected between two adjacent upper chord rods 1-1 are all arranged on the same plane. The lower parallel link 3 includes a plurality of lower chords 3-1 arranged in parallel, two adjacent lower chords 3-1 are fastened and connected by a plurality of lower connecting rods 3-2, and the plurality of lower chords The rods 3-1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com