A coal mine remote automatic sealing system and method

An automatic airtight and remote technology, applied in mining equipment, earthwork drilling, mine/tunnel ventilation, etc., can solve problems such as threatening the life safety of closed construction personnel in fire areas, and achieve a small footprint, easy to use, and ensure life safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

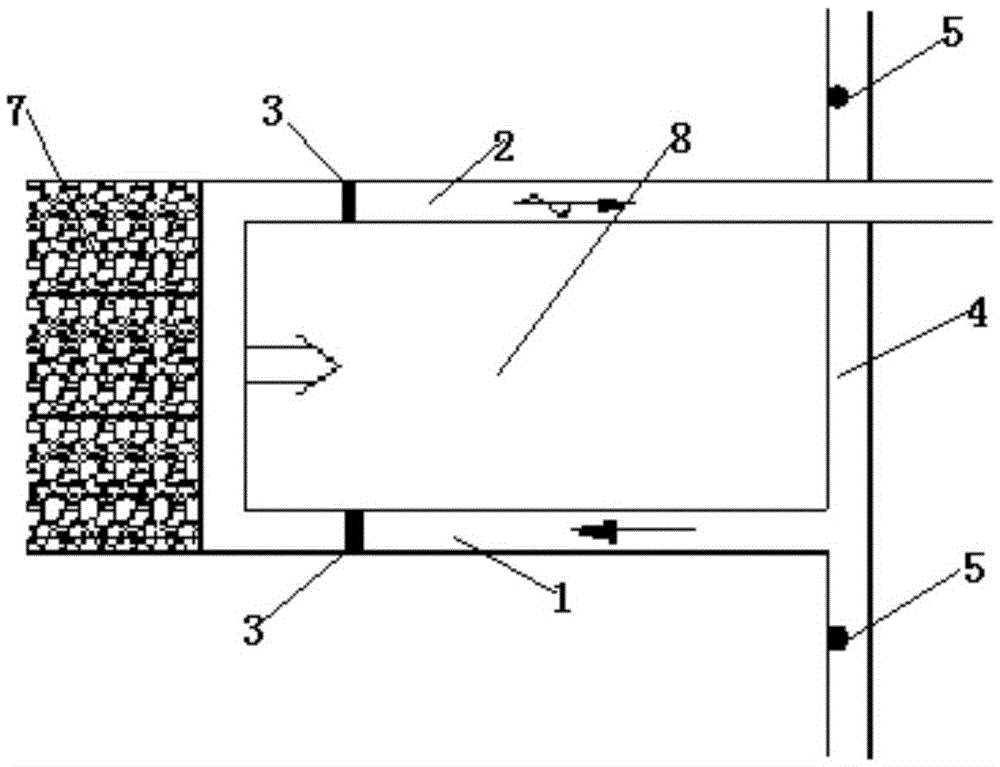

[0015] Such as figure 1 , figure 2 As shown, the coal mine remote automatic sealing system of the present invention includes automatic sealing devices 3 respectively installed in the air inlet tunnel 1 and the air return tunnel 2 of the mine, and a pneumatic switch 5 arranged in the air inlet tunnel 4 .

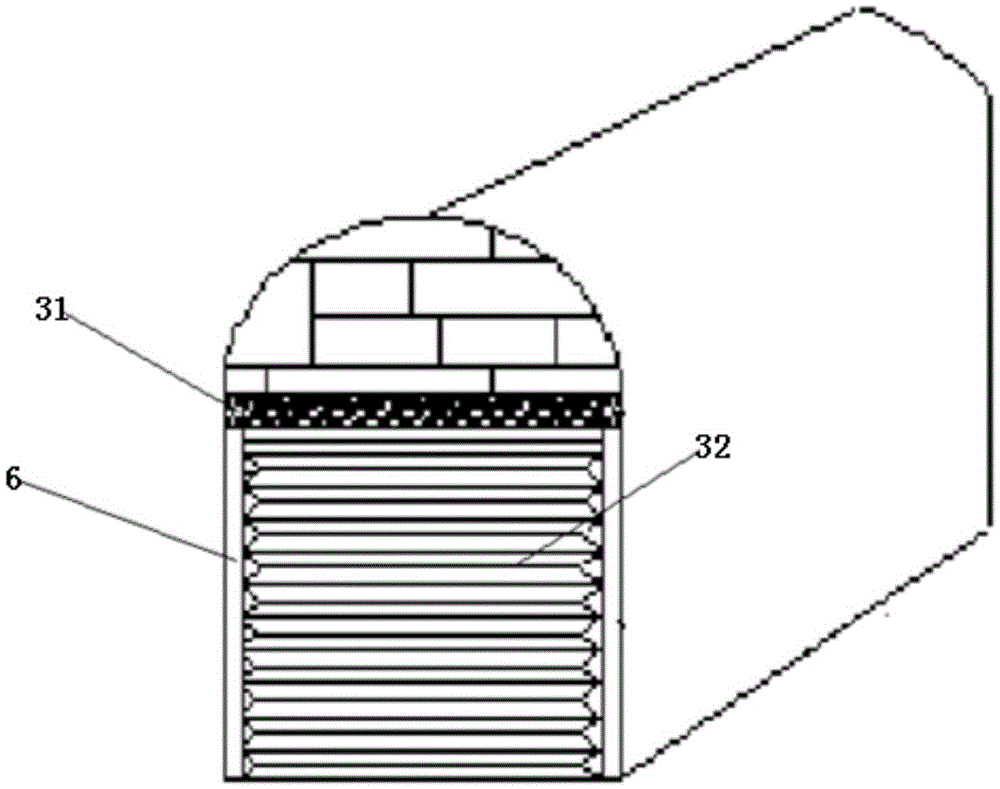

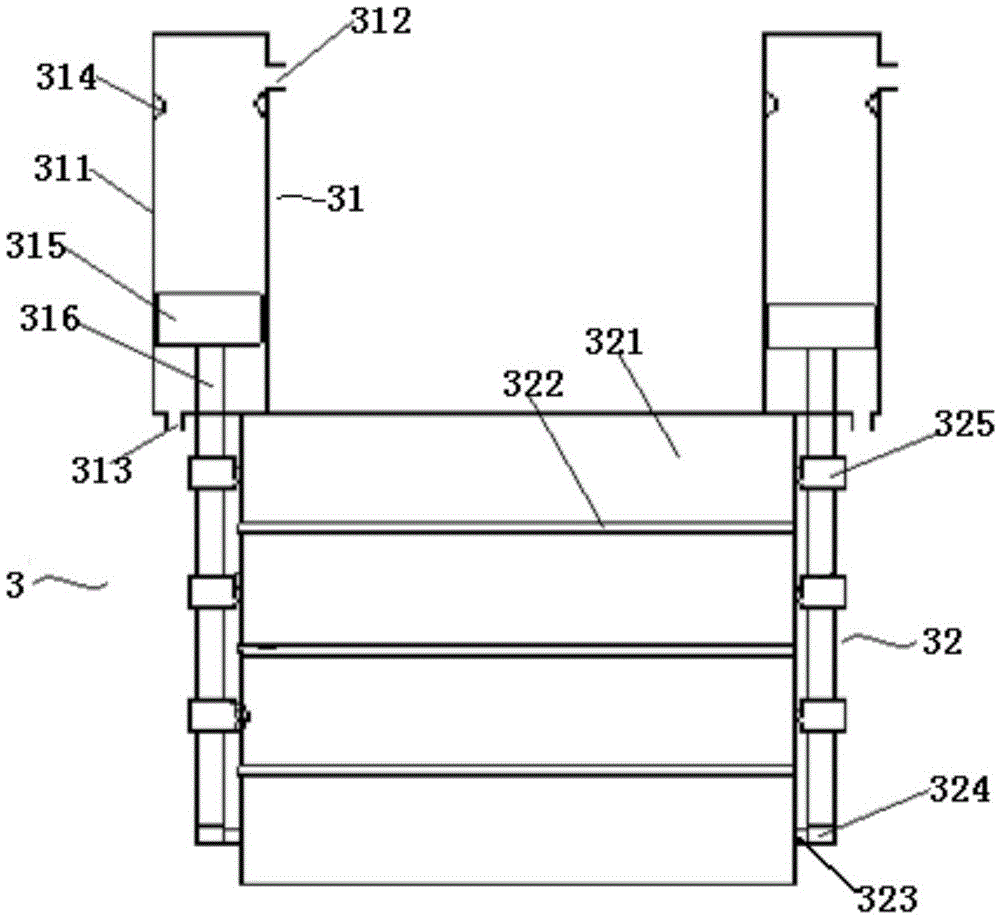

[0016] Such as image 3 As shown, the automatic sealing device 3 includes two pneumatic mechanisms 31 arranged at symmetrical intervals and a folding airtight door mechanism 32 arranged between the two pneumatic mechanisms 31 . Each pneumatic mechanism 31 all comprises a top and a bottom end closed hollow fixed rod 311, and on the top of the fixed rod 311 or on the side wall near the top, offer an upper inflation port 312, at the bottom of the fixed rod 311 or near the bottom On the side wall of the end, the gas charging port 313 is opened, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com