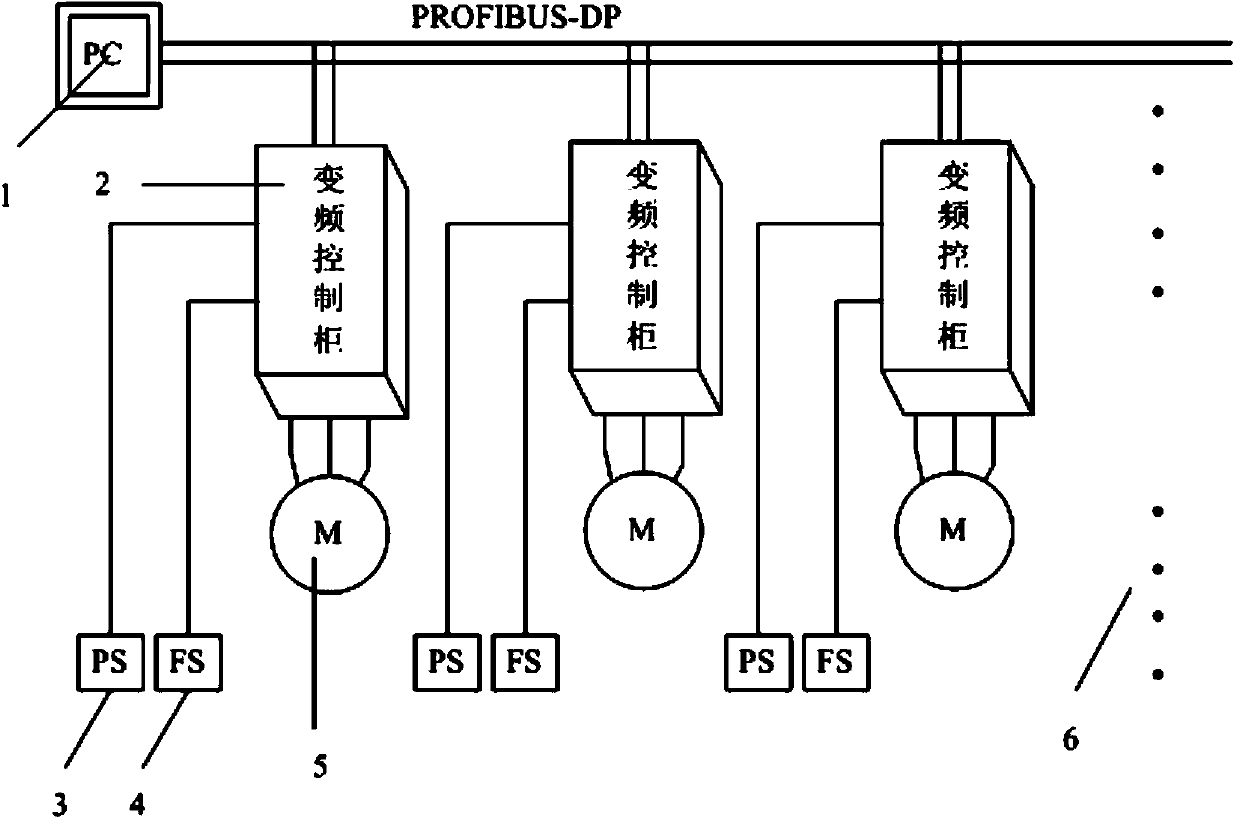

Constant-current frequency conversion control system for brine pumps of freezing station

A frequency conversion control, frequency conversion control cabinet technology, applied in the direction of pump control, liquid variable capacity machinery, machine/engine, etc., can solve the problem of unrealized centralized monitoring of computer networking, inability to compare effective data and collaborative control, low degree of automation, etc. problems, to achieve the effect of improving the degree of automation, improving automation, and improving control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below with reference to the accompanying drawings.

[0023] In this embodiment, the flow sensor installed on the brine pipeline is used to detect the flow of brine in the pipeline, and the flow is converted into an electrical signal and input to the PLC controller, and the PID control method is used in the PLC controller to control, and the output signal Control the output frequency of the frequency converter to change the speed of the brine pump. When the amount of cooling required for freezing increases, the flow rate inside the pipeline is less than the set flow rate. After the flow signal is adjusted by PID, the output frequency of the inverter increases, the speed of the water pump motor increases, and the flow rate of brine becomes larger until it becomes stable; on the contrary, when freezing requires cooling When the flow rate decreases, the flow rate inside the pipeline is greater than the set flow rate. After t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com