Anchor net spraying-steel wire rope oblique cross coupling supporting method

A technology of coupling support and wire rope, applied in the installation of bolts, earthwork drilling, shaft equipment, etc., can solve problems such as the collapse of the roadway roof, the failure of the combined support body of the bolt and the anchor cable, and the damage of the support, so as to achieve the construction Simple operation, good support effect, and the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

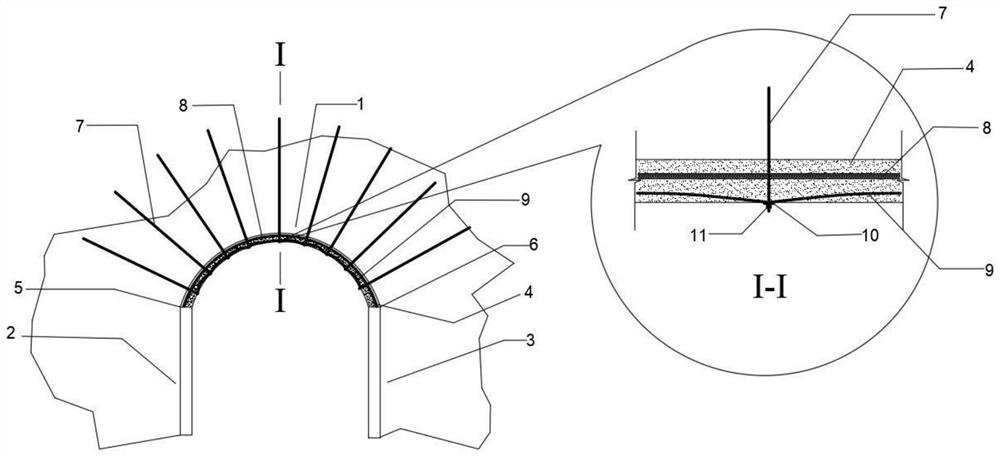

[0025] The present invention is further described below in conjunction with the accompanying drawings and embodiments.

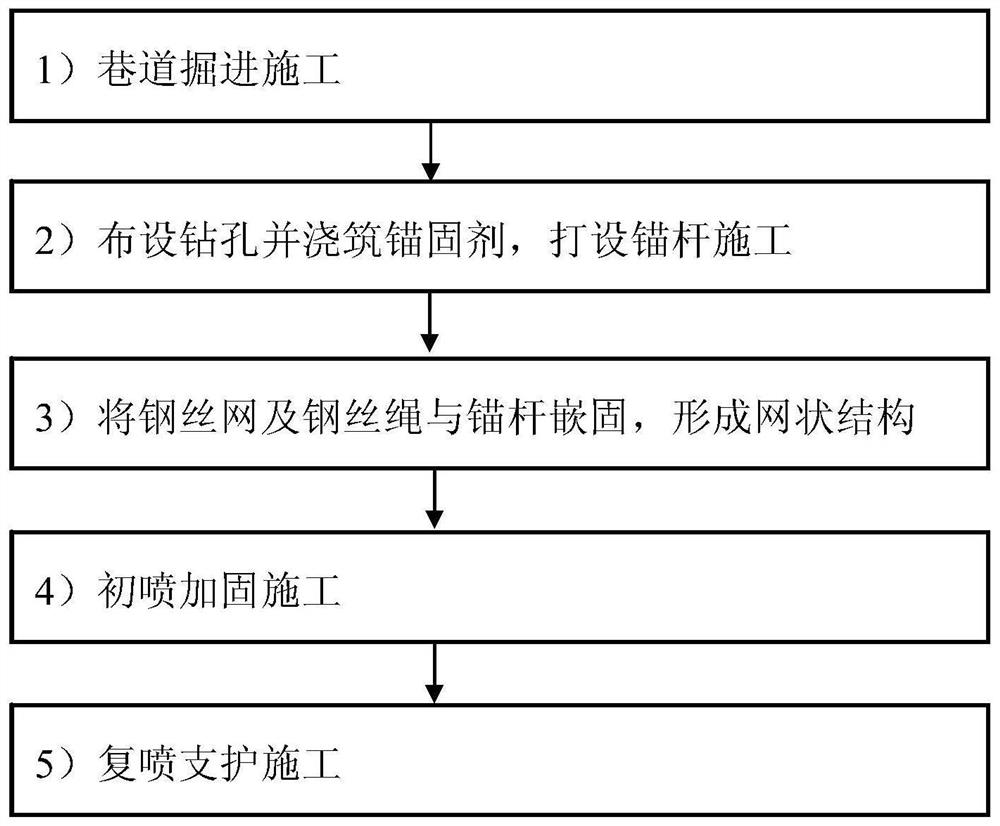

[0026] as Figure 1 As shown, an anchor mesh spray-wire rope obliquely coupled support method, comprising the following steps:

[0027] 1) Roadway tunneling construction.

[0028] In order to reduce the disturbance of the surrounding rock, the excavation roadway is constructed by the smooth blasting method.

[0029] 2) Lay holes in the top plate of the roadway 1, the left shoulder of the roadway 5 and the right shoulder of the roadway 6 and pour the anchoring agent, and lay the anchor rod 7 to the design depth.

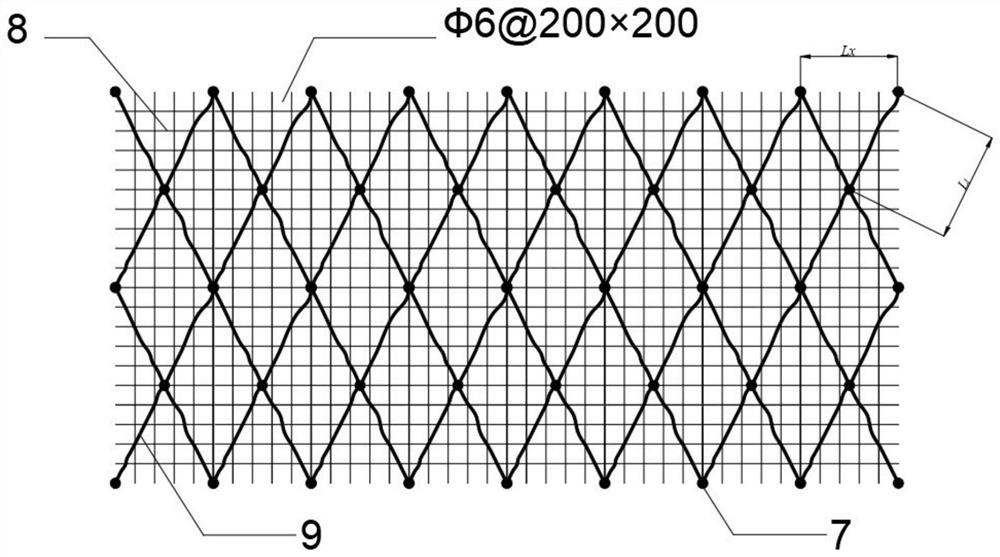

[0030]According to the size of the roadway, in the roadway top plate 1, the left shoulder of the roadway 5 and the right shoulder of the roadway 6 reasonable layout of multiple rows of drilling holes, in the pouring anchor agent drill hole to set anchor 7, multi-row anchor 7 set up, anchor rod 7 using plum blossom arrangement, anchor pallet 10 using stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com