Plastic mechanical sealing and cutting equipment

A plastic machinery and equipment technology, applied in the field of plastic mechanical sealing and cutting equipment, can solve the problems of plastic films sticking together, reducing the flatness of the incision, increasing energy consumption, etc., to reduce the integrity, small tooth gap, and reduce machine energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

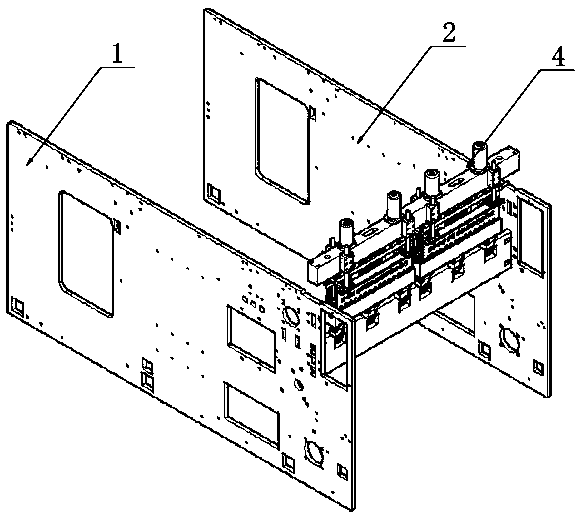

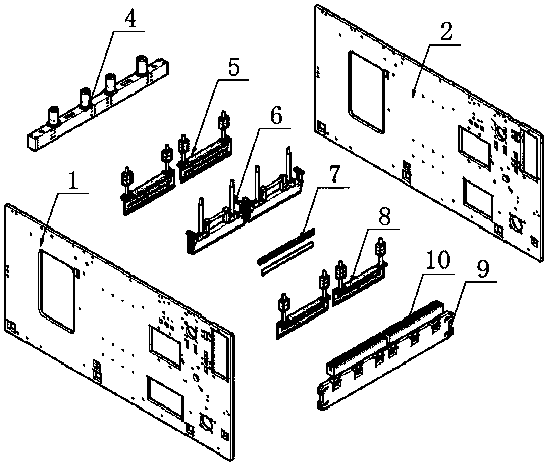

Image

Examples

Embodiment approach

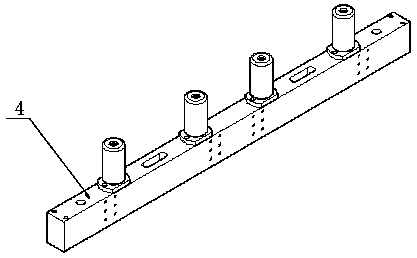

[0038]The embodiment is specifically: the first fixed frame 15 is fixedly connected with one of the guide rods 13, the second fixed frame 17 is fixedly connected with the other group of guide rods 13, and the connecting rod 16 is used to pass through the first fixed frame 15. and the second fixed frame 17, the two are fixedly connected together, so that the sealing knife 6 and the crossbeam 4 are more integrated, and when the sealing knife 6 is heated, the thermal expansion and contraction of the sealing knife 6 are bound by the fixed structure of the guide rod 13 , the position of the guide rod 13 cannot be changed, prolonging the service life of the linear bearing of the guide rod 13, the overall operation of the machine is also more stable, and the installation structure of the sealing knife 6 of the existing sealing and cutting equipment is solved. In order to avoid thermal expansion and contraction, the position of the guide rod 13 changes Squeeze out the bearing, reserve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com