High-temperature double-piston fixing ball valve

A fixed ball valve and double-piston technology, applied to valve devices, cocks including cut-off devices, engine components, etc., can solve the problem that ball valves with double-piston functions cannot be used in high-temperature media, so as to solve high-temperature medium leakage and reduce elastic pressure , good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

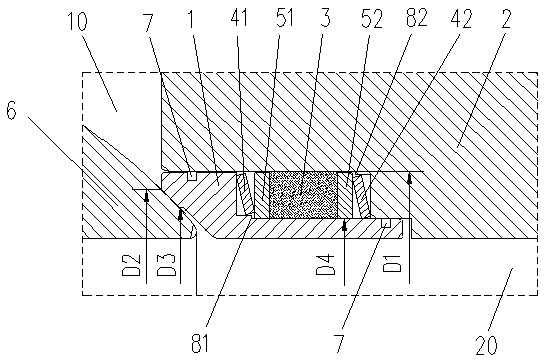

[0028] see figure 1 , a high-temperature double-piston fixed ball valve, which includes a valve seat 1 arranged between a valve cover 2 and a ball 6, the valve seat 1 is in sealing contact with the ball 6, and the valve seat 1 and the valve cover 2 Set the sealing assembly, the sealing assembly includes a sealing body 3, the sealing body 3 is a graphite sealing ring; of course, in other embodiments, it can also be made of other materials that are resistant to high temperatures and have certain deformation capabilities; 3 is an integral structure, which is annular and fills the radial gap between the valve seat 1 and the valve cover 2. The integral sealing assembly 3 is mainly suitable for ball valves with a small thickness of the sealing assembly. Both ends of the sealing body 3 are respectively provided with a first elastic member 41 and a second elastic member 42, and the sealing body 3, the first elastic member 41 and the second elastic member 42 are arranged along the valv...

Embodiment 2

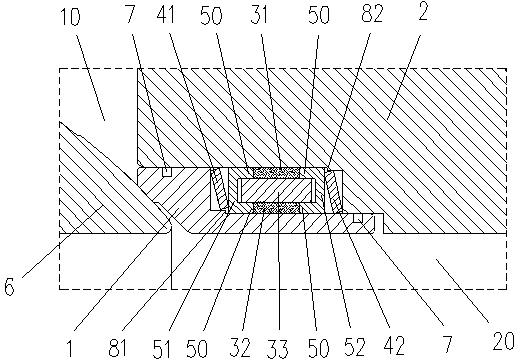

[0038] Since the sealing body 3 is generally made of materials such as graphite that are resistant to high temperatures and have a certain deformability, the thicker the thickness, the greater the initial preload required for the first elastic member 41 and the second elastic member 42. Some ball valves require the sealing body 3 to have a relatively large thickness, which will cause the ball valve to be difficult to operate when it is closed or opened.

[0039] In order to solve this problem, the sealing body 3 in this embodiment includes a first sealing ring 31 and a second sealing ring 32 arranged radially, and the gap between the first sealing ring 31 and the second sealing ring 32 is There is a core ring 33 for separating the first sealing ring 31 from the second sealing ring 32; the first sealing ring 31 seals the gap between the core ring 33 and the valve cover 2 , the second sealing ring 32 seals the gap between the core ring 33 and the valve seat 1 .

[0040] Further...

other Embodiment approach

[0042] In other embodiments, the sealing member 3 can also choose more layers of sealing ring structure according to the situation, and the sealing rings of adjacent layers can be separated by the core ring. Those skilled in the art should understand that as long as the first elastic member and the second elastic member are arranged at both ends of the sealing member 3, and the inner and outer diameters of the sealing assembly and the distance between the inner and outer diameters of the valve seat and the sealing position of the ball are ensured, relationship, a ball valve with dual-piston functions can be obtained, and the above-mentioned structures all belong to the content to be protected by the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com