Color filter film thickness measurement method and device

The technology of a color filter and a measurement method is applied in the field of color filter film thickness measurement method and device, which can solve the problems that the color filter cannot be accurately distinguished and the detected pixel areas are different, so as to avoid the difference in measurement results , Eliminate the effect of measurement error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention is described below by means of the accompanying drawings and specific embodiments.

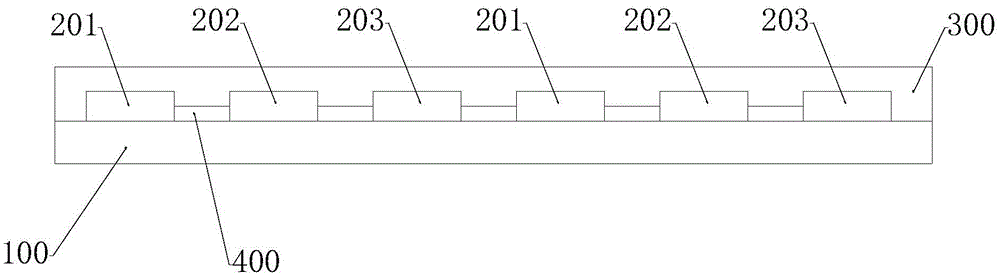

[0034] Such as figure 1 Shown is a schematic cross-sectional structure diagram of a color filter (ColorFilter) used in a TFT-LCD. The color filter includes a glass substrate 100 on the bottom layer, and a layer of opaque black matrix 400 (blackmatrix, BM) is formed on the glass substrate 100 by deposition, coating, etc. Pixel cells of different colors, for example in figure 1 includes red pixel 201 (Rpixel), blue pixel 202 (Bpixel) and green pixel 203 (Gpixel) arranged repeatedly in order. A layer of indium tin oxide 300 (ITO) is covered on these pixel units and the black matrix 400 . When different colors need to be displayed, the TFT circuit corresponding to each pixel unit controls whether it transmits light. Obviously, the thickness of each pixel unit will greatly affect the quality of displayed colors, and the thickness of the black matrix 400 will affect ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com