Tin wave height measuring system and method thereof

A technology of height measurement and tin wave, applied in the field of tin wave height measurement system, it can solve the problems of great influence, loss of audit points, and influence on the determination of customers to place orders, so as to avoid measurement differences and ambiguity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

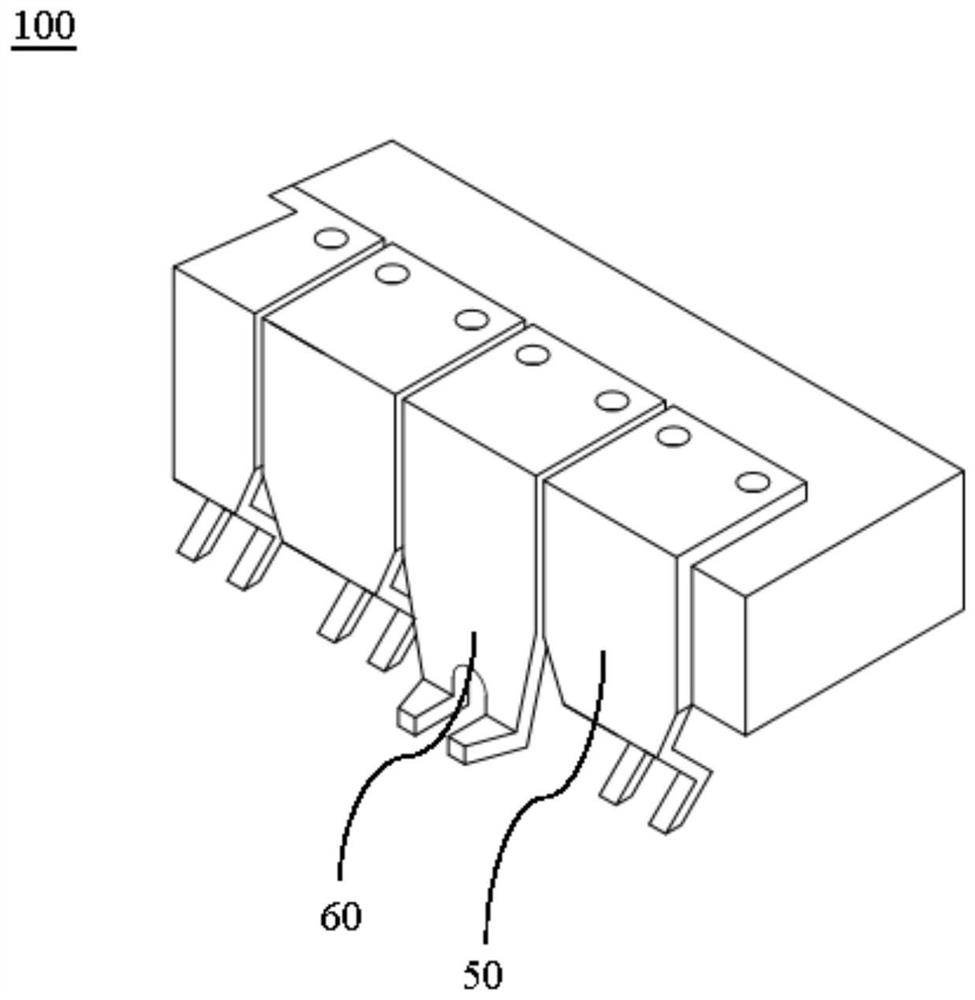

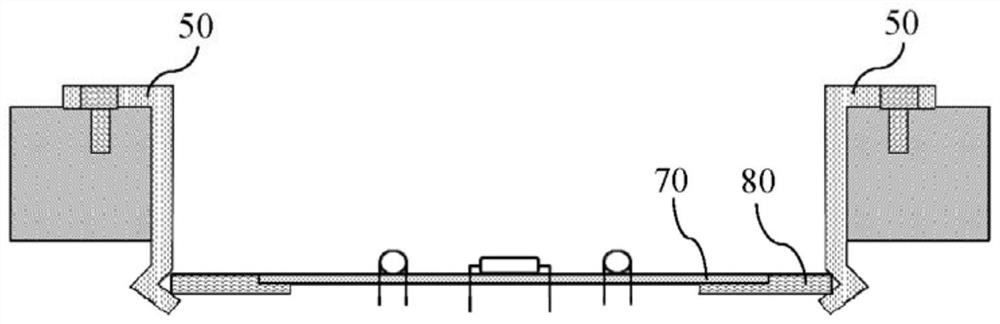

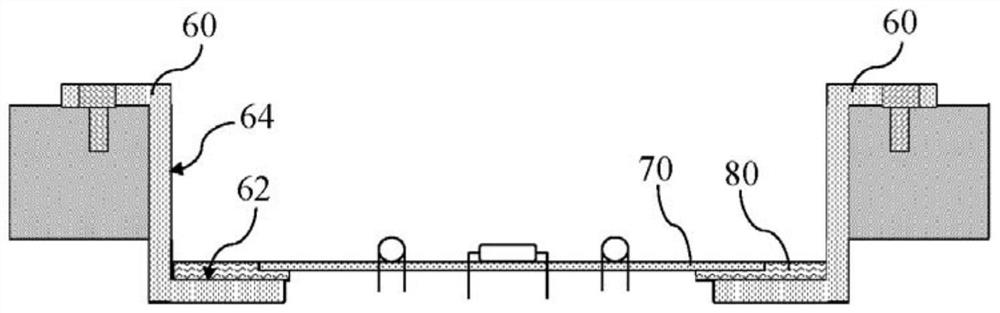

Image

Examples

Embodiment Construction

[0045] Before explaining the tin wave height measuring system disclosed in the present invention and its method, the nouns defined by the present invention are described first. The measurement controller and display device included in the tin wave height measuring system of the present invention can mainly be used It can be realized by hardware, and it can work together with software or firmware. Wherein, the software or firmware used in the implementation can be stored on a machine-readable storage medium, such as: read-only memory (ROM), random access memory (RAM), magnetic disk storage medium, optical storage medium, flash memory devices, etc., and may be executed by one or more general or special purpose programmable microprocessors. The transmission of signals and data can be carried out between the electric slide table and the measurement controller and between the display device and the measurement controller in a wireless or wired manner.

[0046] The implementation o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com