Quantitative measurement method for trace/ultra-trace impurities in high-purity rare earth oxides

A rare earth oxide and impurity technology, which is applied in the direction of measuring devices, test sample preparation, sampling, etc., to achieve accurate measurement, avoid element loss and pollution, and improve analysis efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described below by way of a specific embodiment, but the present invention is not limited thereto.

[0041]The experimental methods used in the following examples are not particularly illustrative, all of which are conventional methods; those used in the following examples, such as non-special descriptions, can be obtained from the business pathway.

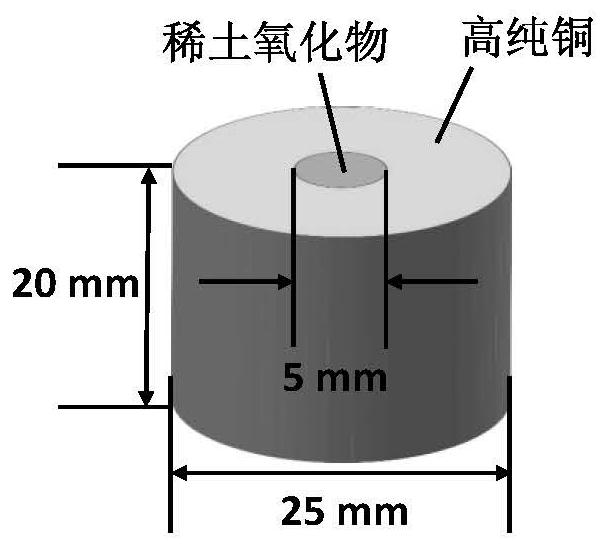

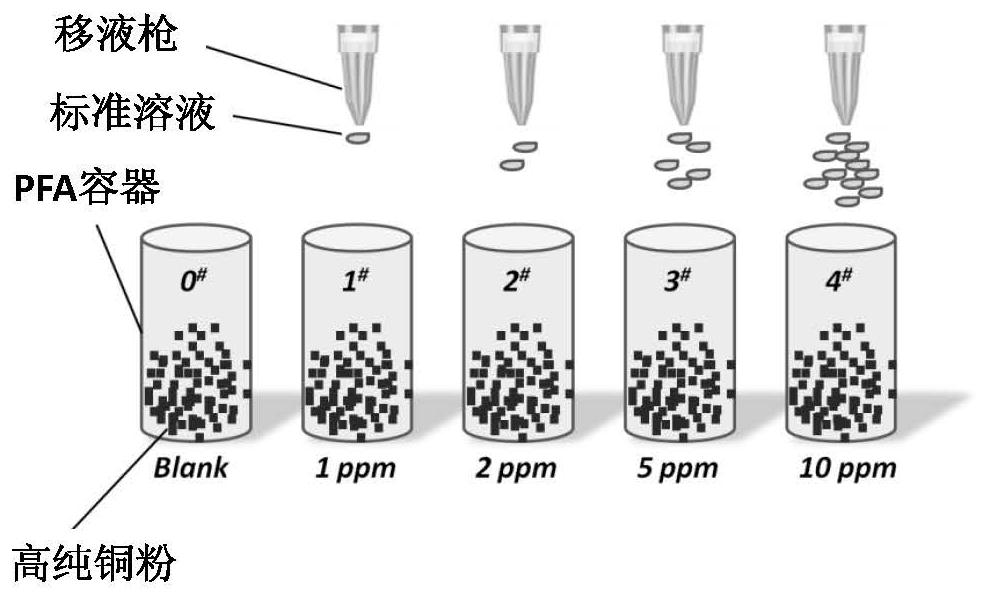

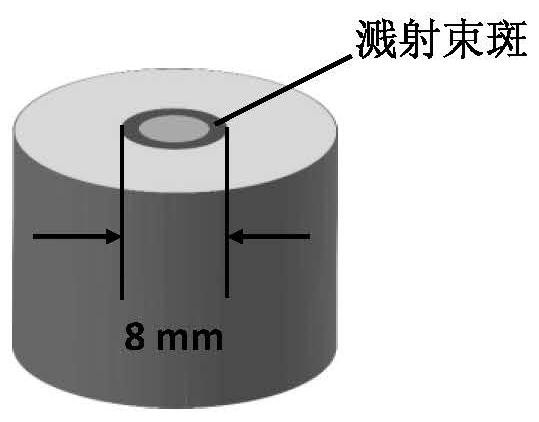

[0042] The high purity cerium oxide sample (~ 0.5 g) is applied, and one side through hole of the conductive assistance device (high pure copper column) is applied, and 10s is pressed with the pressure of 0.5 MPa with the compression bar and the compression machine. To ensure rare earth oxide density while ensuring that the surface of the sample is flush with the other side surface of the conductive auxiliary device. The high-purity copper column filled with high purity cerium oxide samples is placed in GDMS for detection, sputtering, and the signal to be electrically die Cu is stable, data collec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com