Quantitative measurement method for trace/ultra-trace impurities in high-purity rare-earth oxide

A rare earth oxide and impurity technology, which is applied in the direction of measuring devices, test sample preparation, sampling, etc., to achieve accurate measurement, avoid element loss and pollution, and improve analysis efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described below through specific examples, but the present invention is not limited thereto.

[0041]The experimental methods used in the following examples are conventional methods unless otherwise specified; the reagents and materials used in the following examples can be obtained from commercial sources unless otherwise specified.

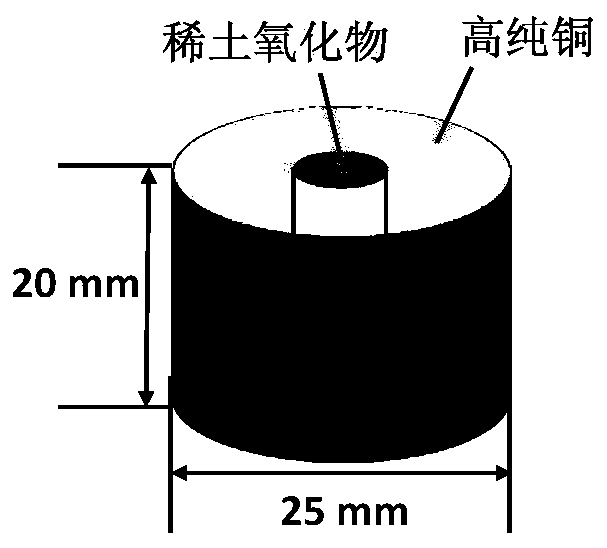

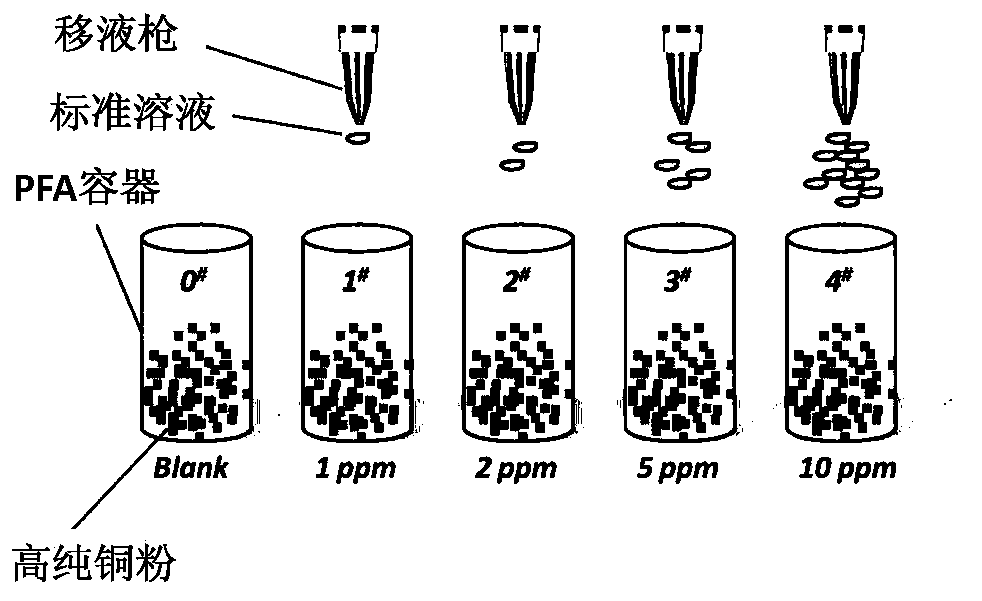

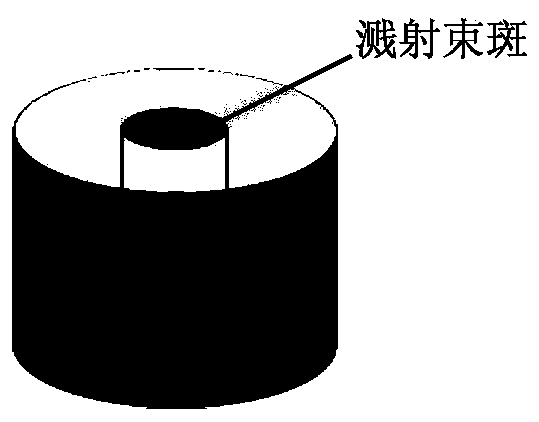

[0042] Take an appropriate amount of high-purity lanthanum oxide sample (~0.5g), put it into the through hole on one side of the conductive auxiliary device (high-purity copper cylinder), and press it for 10s at a pressure of 0.5MPa with a supporting pressure rod and a tablet press, to Ensure the density of rare earth oxides, and at the same time ensure that the surface of the sample is flush with the surface on the other side of the conductive auxiliary device. Place the high-purity copper cylinder loaded with high-purity lanthanum oxide samples in GDMS for detection and sputtering. After the signals of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com