Apparatus for on-site detection of holes in tube

An on-site detection and pipeline technology, applied in the direction of material magnetic variables, etc., can solve the problems of complex signal channels, too many detection components, and high price, and achieve the advantages of simple sensing structure, improved sensitivity and signal-to-noise ratio, and good real-time detection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

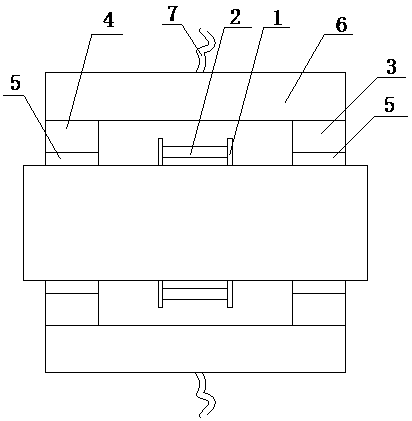

Image

Examples

Embodiment Construction

[0009] The present invention will be described in more detail below in conjunction with the accompanying drawings and embodiments.

[0010] As shown in the figure, the present invention is a device for on-site detection of holes in pipelines, including a plurality of magnetic gathering rings 1 annularly distributed on the same section, with Hall elements 2 on the magnetic gathering rings 1, each Ring 1 is all positioned between permanent magnet one 3 and permanent magnet two 4, and each permanent magnet one 3 is positioned on the same cross section, and each permanent magnet two 4 is positioned on the same cross section, and permanent magnet one 3 and permanent magnet two 4 different magnetic poles are opposite, permanent Both magnet one 3 and permanent magnet two 4 are connected to the pipeline to be tested through the pole shoe 5 on one side, and the other side of permanent magnet one 3 and permanent magnet two 4 are connected through lining iron 6, and permanent magnet one 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com