Method for solving flexible job-shop scheduling problem with improved GA based on polychromatic set hierarchical structure

A technology of workshop scheduling and hierarchical structure, applied in the direction of gene model, data processing application, prediction, etc., can solve the problems of many invalid data, large gap, long chromosomes, etc., to improve the solution speed, reduce the scale and data volume, and improve the search The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

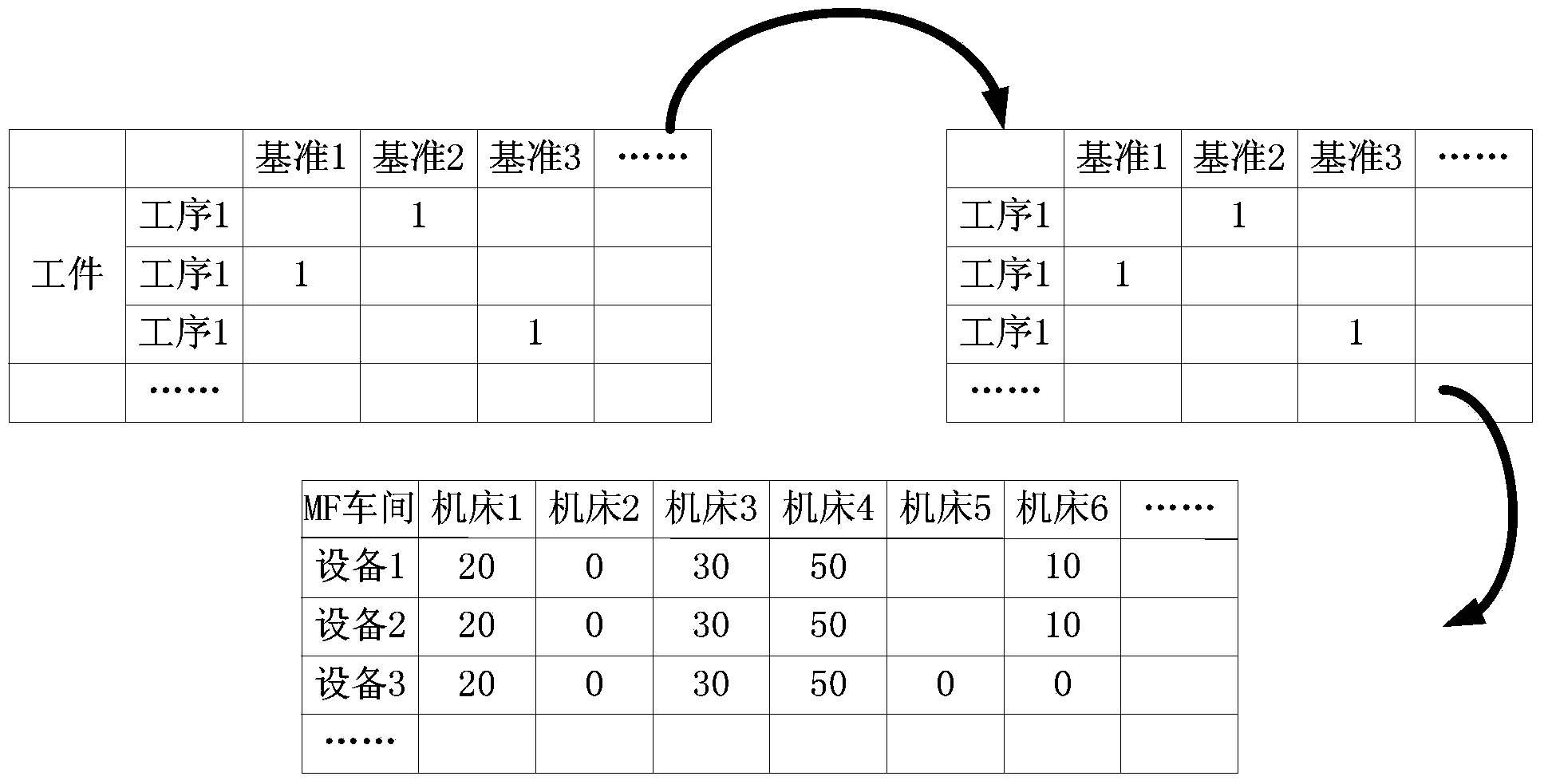

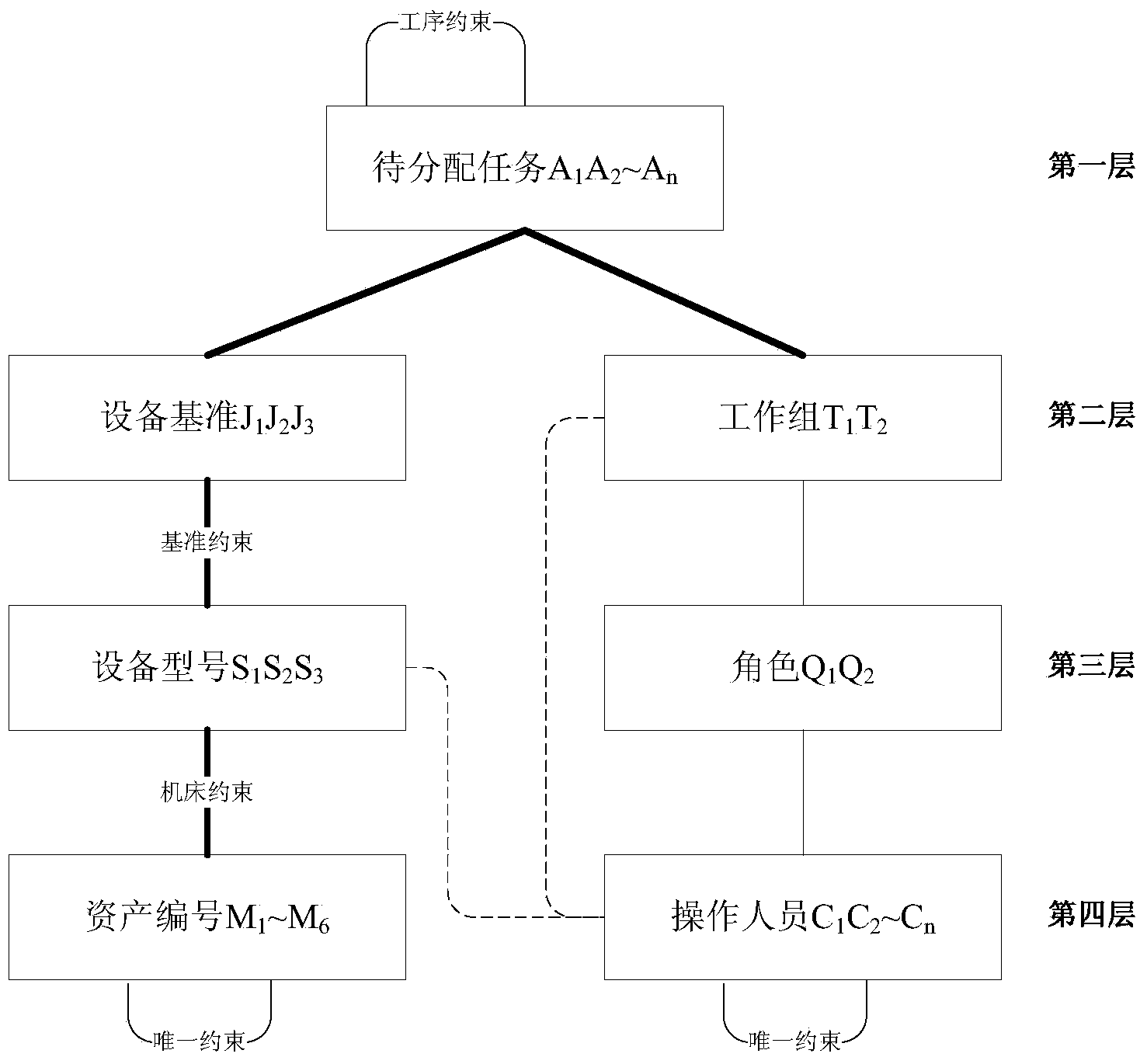

[0062] 1) Mathematical model of flexible shop scheduling problem

[0063] FJSP can be described as, assuming that M is the number of processing equipment, N is the number of workpieces to be processed, P is the number of processes, and I is the set of all equipment; I eg Represents the set of available equipment for the gth process of the workpiece e, J e is the process number of workpiece e; X is the processing sequence of all workpieces, S egk Indicates the start time of the gth process of workpiece e processed on equipment k; E egk is the processing end time of the gth process of the workpiece e on the equipment k; T egk is the continuous processing time of the gth process of workpiece e on equipment k, and k∈I eg then there is E egk =S egk +T egk ;E p Indicates the completion time of the last process; MS indicates the final completion time of all workpieces;

[0064] When the j-th process of workpiece i and the g-th process of workpiece e are executed on the same...

example 1

[0163] Example 1 simulation:

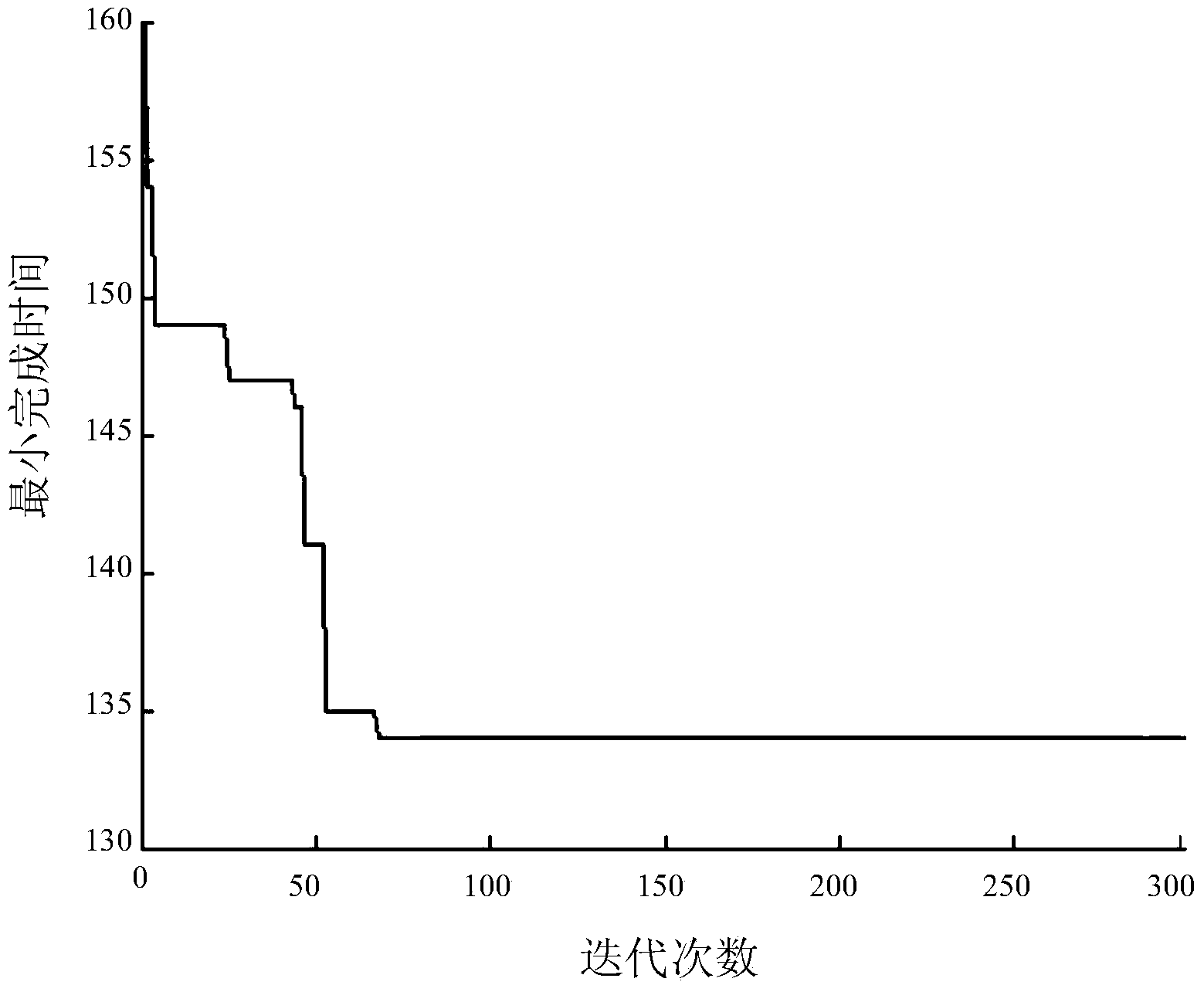

[0164] For the calculation example in Table 1, the parameters of the genetic algorithm are set as follows: the population size is 50, the crossover rate is 0.6, the mutation rate is 0.8, and the maximum number of evolutionary bands is 100. The GA evolution curve is obtained by simulation in the MATILAB7.0 environment: image 3 shown by image 3 It can be seen that the improved GA algorithm can quickly converge from 147 to 134 in the 70th generation, and the corresponding scheduling result Gantt diagram is as follows Figure 4 shown.

example 2

[0165] Example 2 simulation and comparison:

[0166] In order to further verify the correctness of the algorithm, choose Example 2 for simulation, set 2 process benchmarks, 4 equipment numbers, and 8 specific equipment, and the optimal solution is 121 minutes. Depend on Figure 5 The genetic evolution curve shows that the improved genetic algorithm can quickly converge from 130 to 121 in the 32nd generation, and its solution speed is obviously faster. The corresponding Gantt diagram of the scheduling result is as follows Figure 6 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com